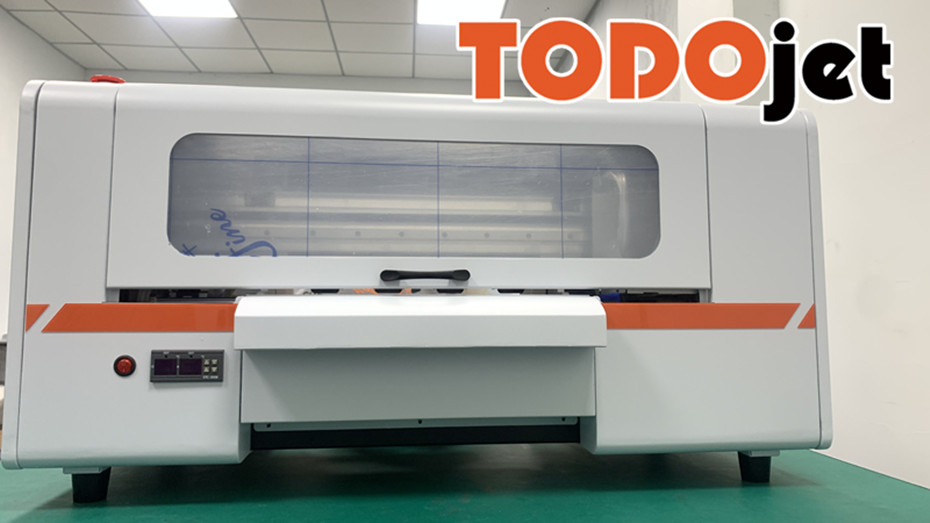

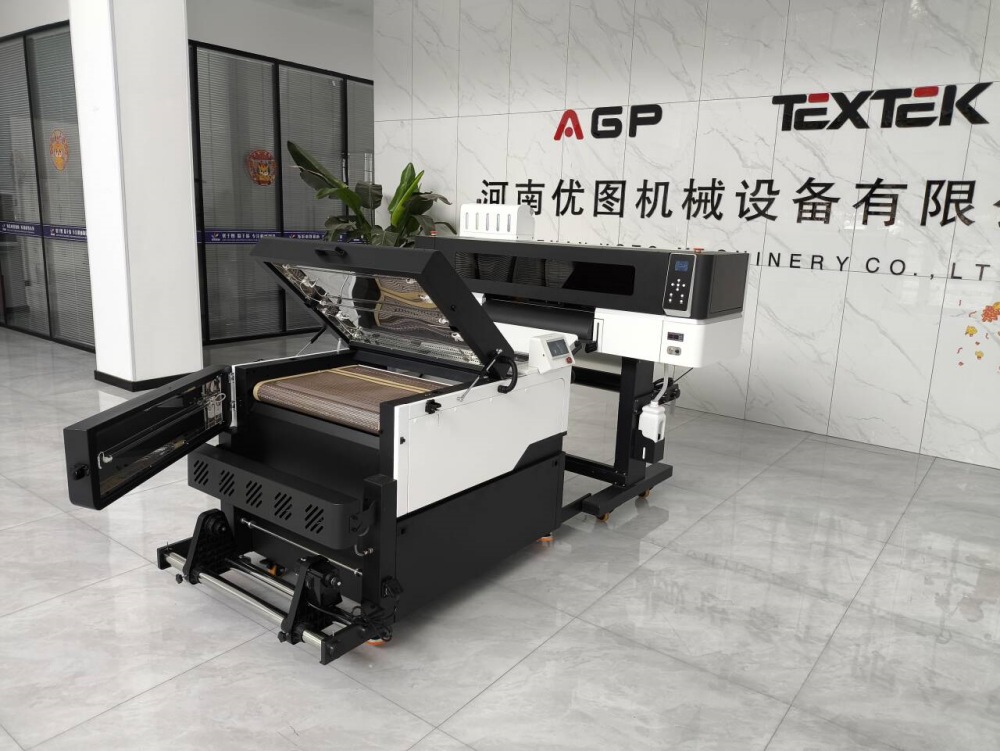

2 Head xp600 Digital DTF Printer Machine A3 PET Film T-shirt Printing Machine White Pigment Ink Shake Powder

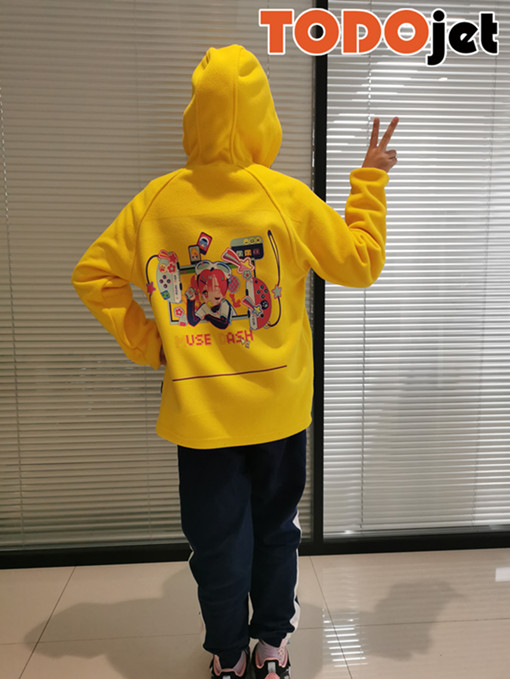

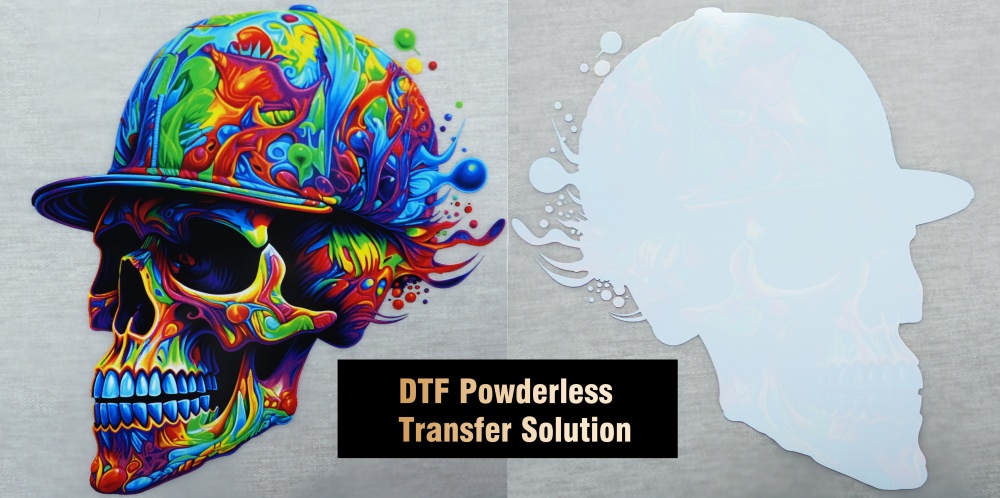

The complexity of the pattern is not subject to any restriction, the full-color gradient color can be printed at one time, and the machine automatically matches colors.

The biggest advantage of the T-shirt printing machine is that it is not limited by the batch size, one piece is printed, and the single piece cost will not increase because of the small batch.

1. Prepare the pattern to be printed, use PS software to color, retouch and cut out the picture, and then lay a white ink layer through the spot color channel, and thicken the white ink in the light-colored part, and the printing effect is better.

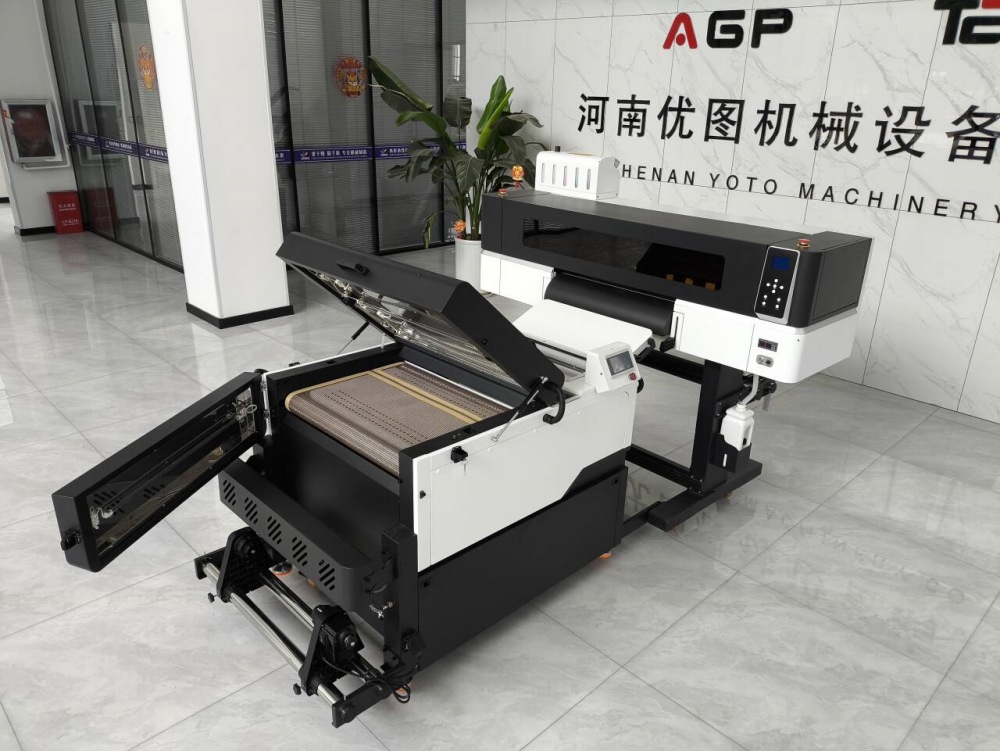

2. Open the printing software Print_System_Net, perform data analysis, transfer the pattern to be printed to the heat transfer printer through data, and prepare to start printing

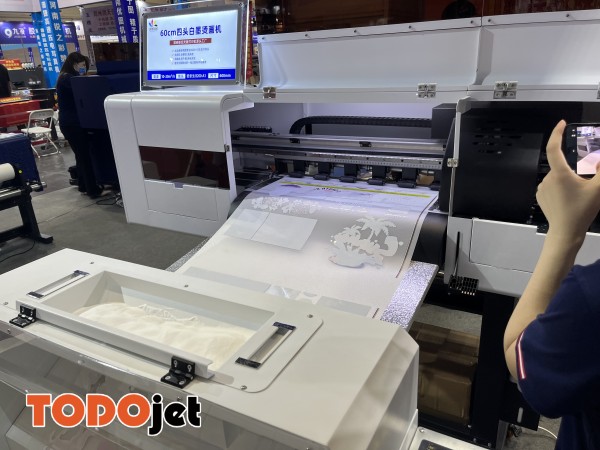

3. The offset heat transfer printer starts to print, the white color comes out at the same time, the color is below, and the white is covered. It can print any color pattern. The printed pattern is hollowed out, and there is no need for lamination and lettering.

4. In the printing part, Taituo Digital has a new technological breakthrough, which is the patented “one-key ventilation” printing mode. Customers can choose conventional printing and ventilation hole printing according to their needs, especially for large-area patterns , breathable mode printing, soft to the touch, the ink is compatible with the fabric, and it is close to the direct injection effect.

5. Output to the powder shaker for automatic powder feeding, powder shaking, and even powder shaking

6. The belt conveys the heat transfer and heats the hot melt powder. The temperature is about 160 degrees. The whole baking process takes about 2-3 minutes. The baking is uniform and the dry and wet rubbing fastness of the pattern is increased.

7. The heat transfer after shaking the powder is cut, and pressed with a heat transfer pressing machine. The temperature is controlled at about 160-170 degrees, and the heat is pressed for about 18-20 seconds.

8. After standing for 1 minute, cold tear the film, the customized T-shirt is completed, soft to the touch and beautiful color