To understand the prospects of the UV printer market, we can start from the three aspects of the UV printer equipment itself, the materials that can be printed, and the application industry.

One; UV printer equipment itself

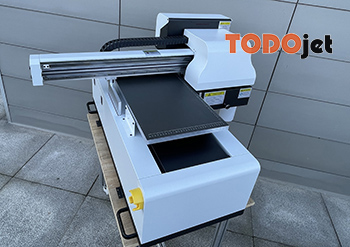

1. In terms of print heads: The print heads used by UV printers on the market are divided into two parts, one is industrial print heads, mainly Ricoh print heads, mainly used by large machines, expensive, and the pursuit of printing speed. One is commercial sprinklers, mainly Epson sprinklers. Mostly used in small and medium-sized machines, the price is relatively cheap, and the pursuit is printing accuracy. The two complement each other.

2. Ink types: UV printers can print on a variety of materials. For this, UV inks are also divided into multiple types according to different product materials. UV hard ink used in hard materials such as stone, glass, metal, ceramics, wood, etc. UV soft ink specially used for soft materials such as PVC and TPU. Leather stretching ink for leather. There is also a solvent ink.

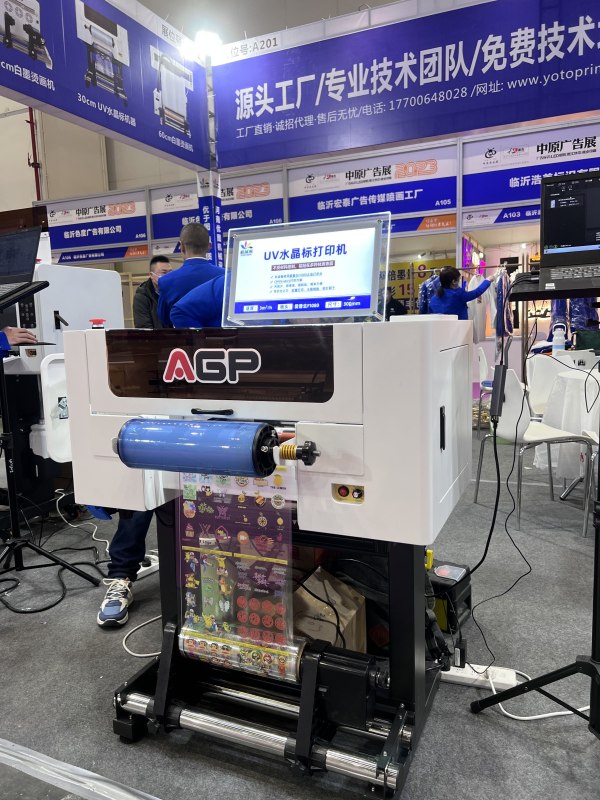

3. The number of nozzles; early UV printers were mostly modified machines, and white ink and color ink shared a nozzle. Take the commercial nozzle machine as an example. For a six-channel nozzle, four channels correspond to C M Y K four-color ink, and the remaining two channels correspond to W (white ink). Form a sequence configuration of CMYK+WW. After the host machine appeared later, choose two standard nozzles, one for each white color. Form CMCMYK (color ink) + WWWWW (white ink) sequence.

2. Materials and products that UV printers can print

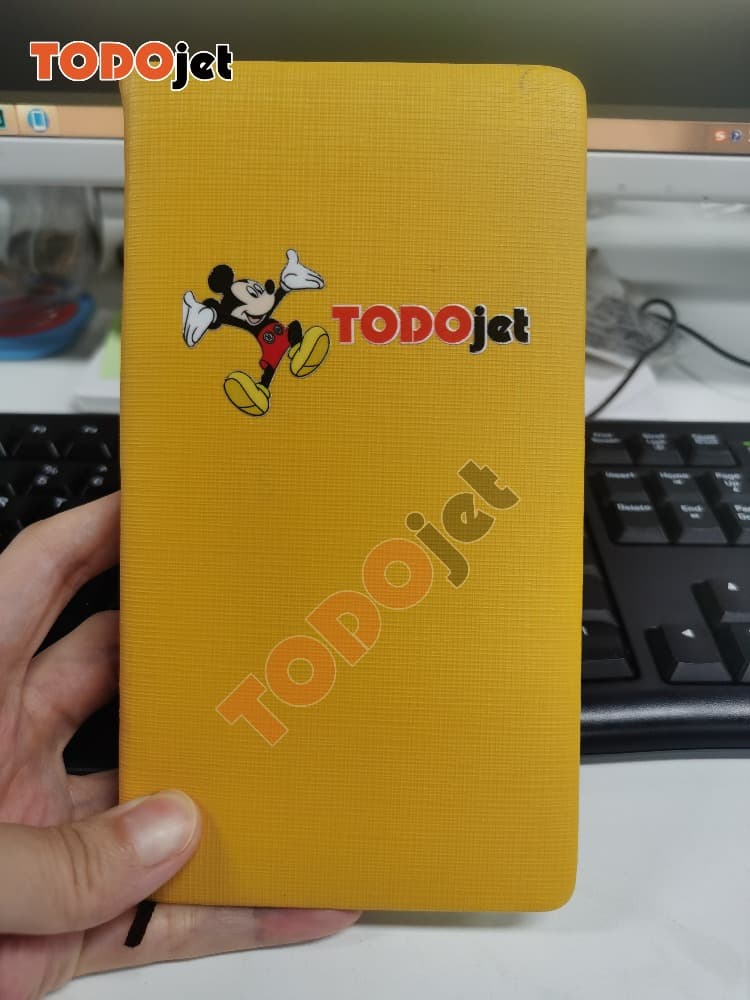

1. Early UV printers could only print flat materials. After years of development, they have now developed to print flat, cylindrical, sphere, and micro-curved products. Such as acrylic, wood, packaging boxes, wine bottles, mugs, vacuum flasks, lampshades, basketballs, signature pens and other products. The print drop of commercial nozzles can be up to 3.5mm. It is believed that in the future, it can be developed to achieve printing of products with greater gaps.

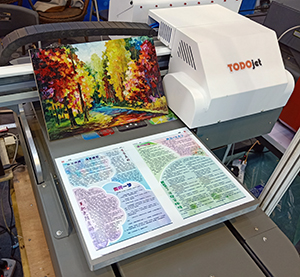

2. The product can be printed by UV printer, which can print plane and embossed effect as required. The relief effect can be freely selected from partial relief, full relief, and micro relief. The relief effect is actually stacked by increasing the white ink printing multiple.

Three, UV flatbed printer application industry

2. Building materials industry: ceramic tiles, glass, leather.

3. Advertising industry: canvas, advertising boards, signs.

4. Handicraft industry: keychains, pendants, fake nails, lipstick tubes.