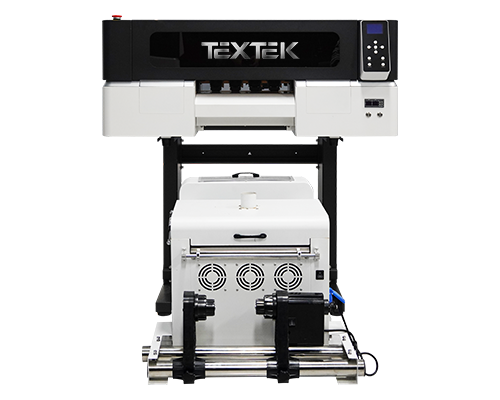

2024 Hot Sale 30cm DTF Printer with PET Film Heat Transfer and Shaking Powder Machine

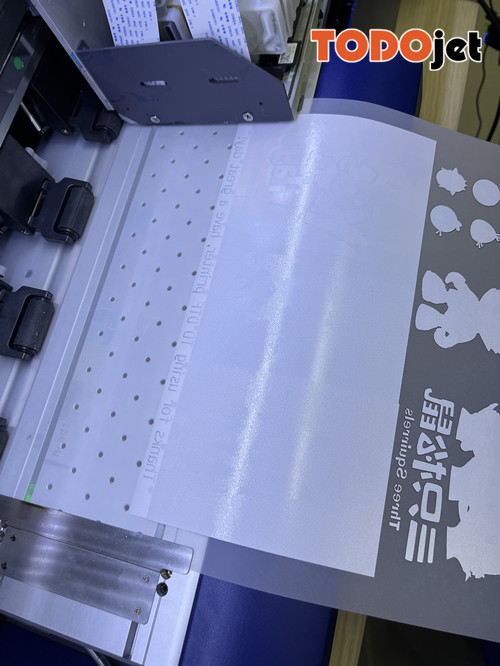

The white ink stirring function ensures continuous circulation and stirring of the white ink, which effectively prevents ink precipitation and reduces the risk of printer failures. Additionally, this function guarantees stable white ink output upon startup, enhancing the overall printing quality and reliability.

The white ink stirring function ensures continuous circulation and stirring of the white ink, which effectively prevents ink precipitation and reduces the risk of printer failures. Additionally, this function guarantees stable white ink output upon startup, enhancing the overall printing quality and reliability.

Imaging Beyond Your Imagination Every Time

The white ink stirring function allows the white ink to circulate and stir, thereby effectively inhibiting ink precipitation and preventing failures. This also ensures the stable output of white ink when the printer is started.

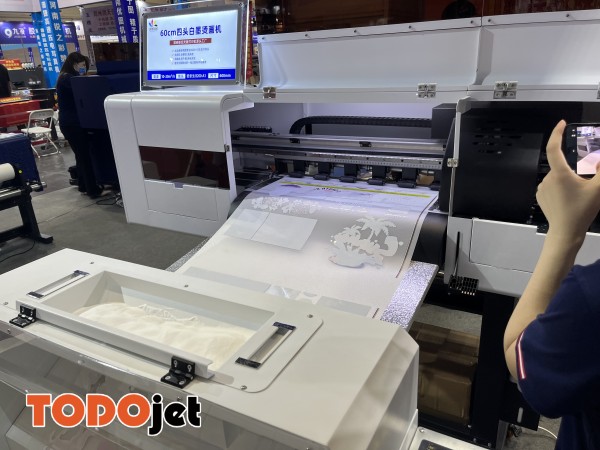

DTF Printer: Save Worry, Effort, and Time with New Advantages

Advanced Features:

- White Ink and Environment-Friendly Paint Heat Transfer Solution: A revolutionary garment heat transfer application that overcomes fabric selection issues associated with direct-injection printing processes.

- Versatile Material Transfer: The new heat transfer process is not restricted to specific materials, eliminating concerns about color difference and color fastness.

- Efficient Production: The process requires no engraving, waste discharge, or lamination, which improves production efficiency.

- Unlimited Patterns: The system supports natural hollowing, resulting in lighter, thinner, breathable transfers with a short cycle and fast delivery.

- Cost-Effective: No need for high investment in equipment and venues, making it cost-effective from the very first piece.

By breaking through the limitations of traditional color registration plate making, this new heat transfer solution offers flexibility and reduces investment costs significantly.