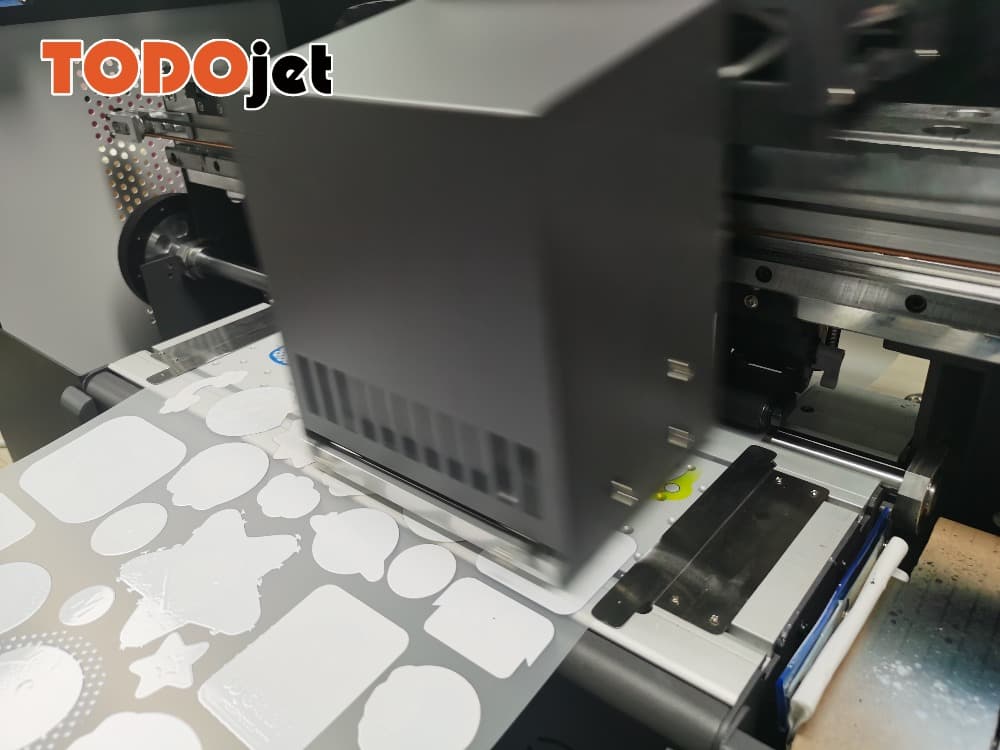

30cm A3 DTF Printer and Shaker Machine XP600 Model

DTF Printers (Direct to Film Printers) are capable of printing to cotton, silk, polyester, denim, and more.

With the advancement in DTF technology, there is no denying that DTF is taking the printing industry by storm.

It is quickly becoming one of the most popular technologies for textile printing compared to traditional printing methods.

Advantages:

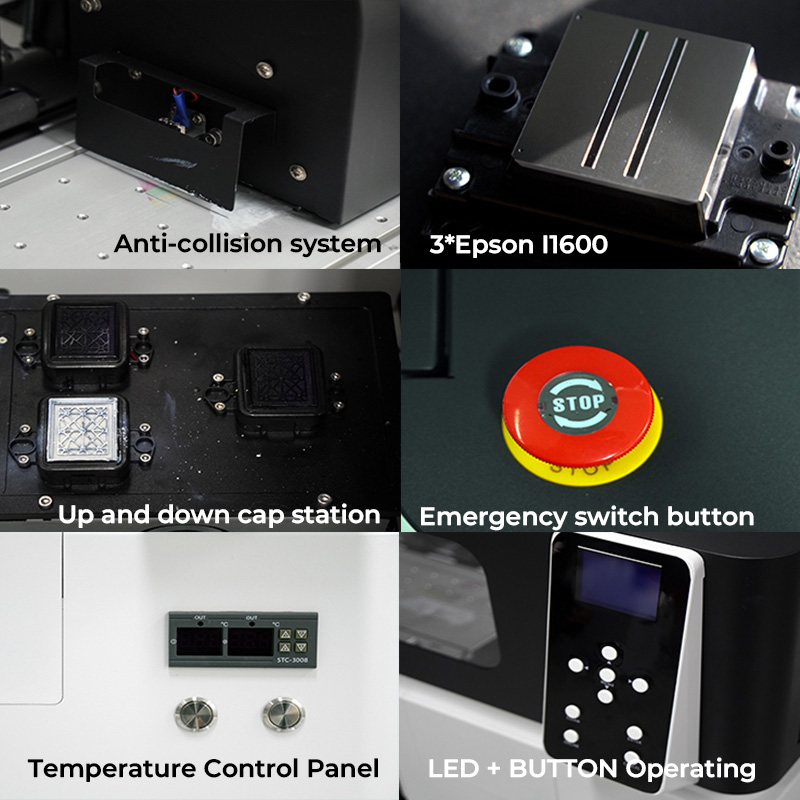

1. Good fastness, long life, good stability, good performance, and high precision

2. No restrictions on patterns, natural hollowing is lighter and breathable

3. No need for engraving, waste removal, and lamination, effectively improving production efficiency

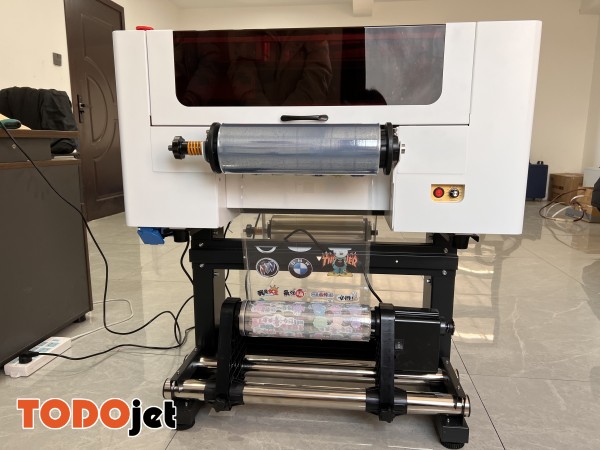

4. Small footprint, one-person operation, water washing

5. Suitable for any fabric, light/dark fabric together

6. Application field: Any fabric can be printed, and one machine can solve all problems in the garment printing industry. Use to print clothing T-shirts, leather, pillows, hats, sweaters, etc.

Personalized customization, one piece is printed, white and color are produced, suitable for various colors, printing on fabrics, leather, jeans, etc. to enhance market competitiveness; small footprint, can be used in various factories, homes courtyard workshops, and Amazon stores are an excellent choice for start-ups and the best equipment supplement for major garment factories.