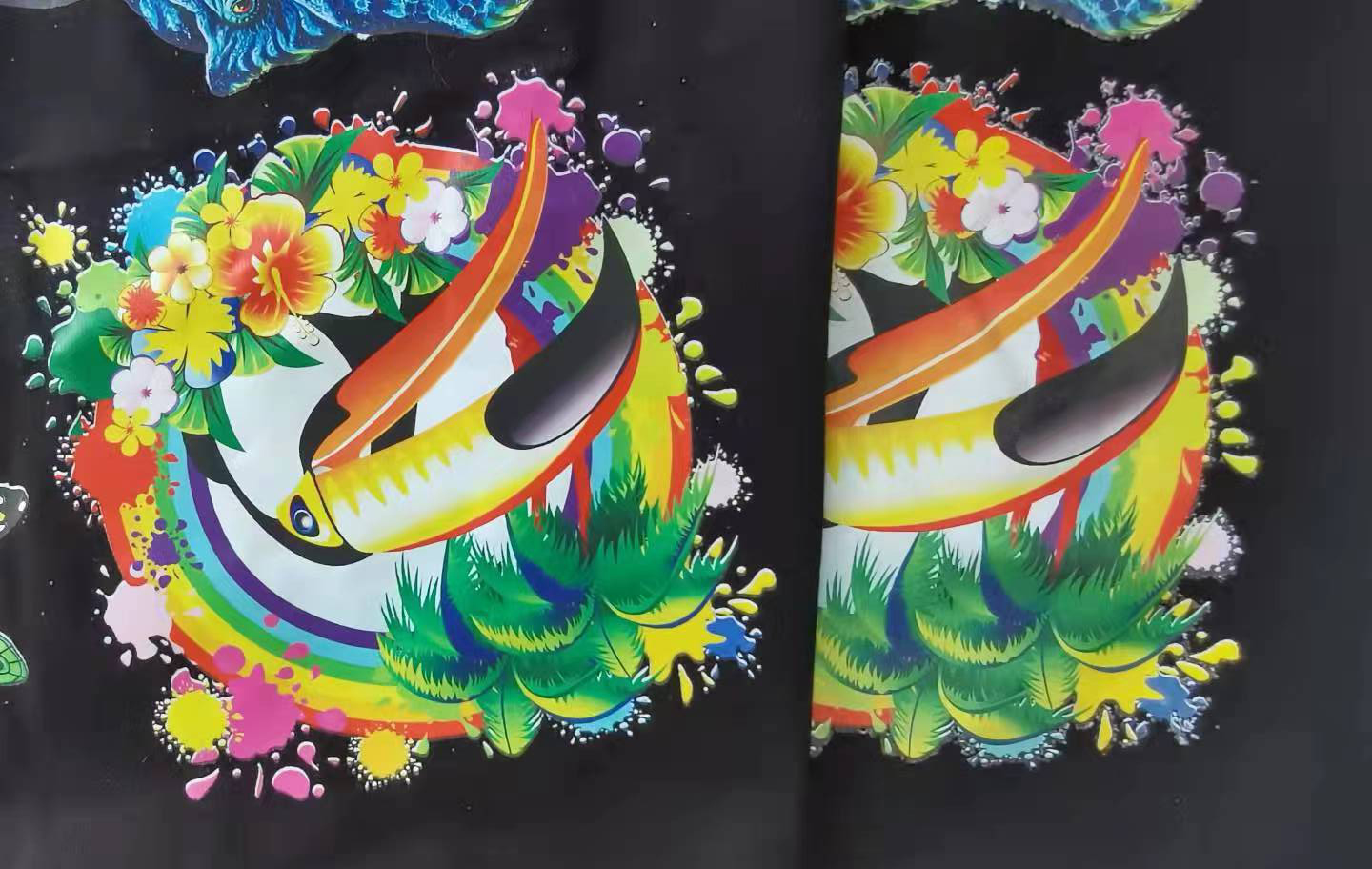

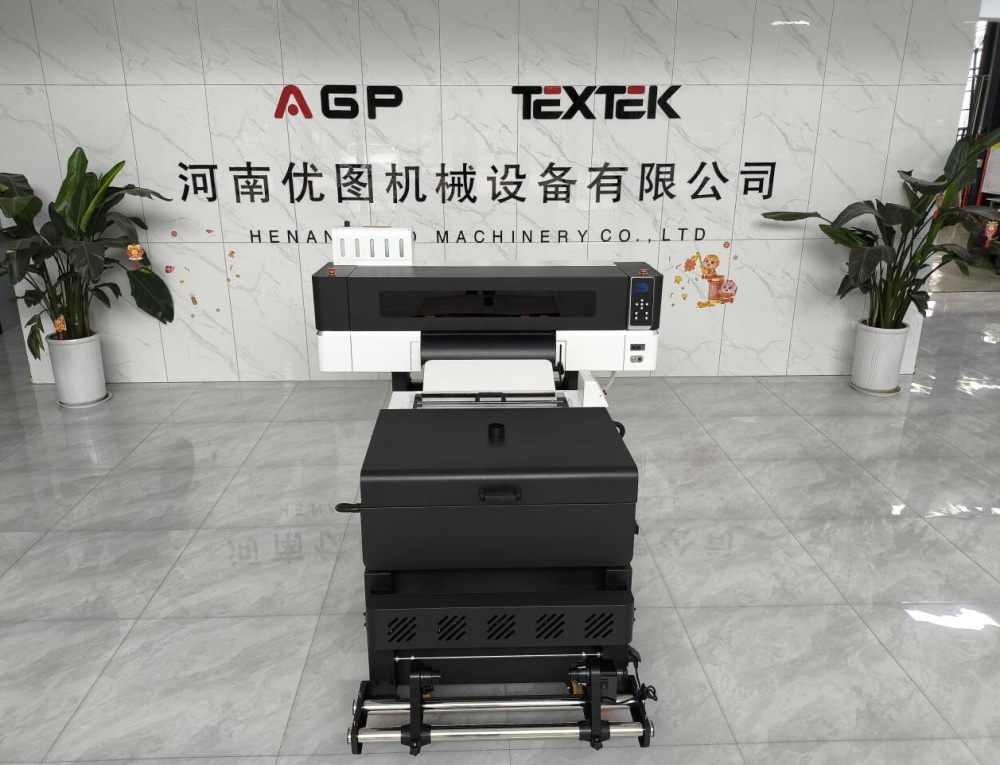

30cm Double XP600 Printing Impresoras Wholesale Roll to Roll A3 DTF Printer with Shaker Powder Machine

DTF printing is a new technology created for high-quality textile printing. The DTF of the English Direct Transfer Film includes printing the design directly on the film, and then using heat to transfer it to the garment, directly printing on the fabric, for fashion and decoration applications.

Product form

| Product name | Digital Heat transfer PET Film T-Shirt Printer |

| Print head number | 1/2 pcs |

| Print head | XP600 |

| Media Type | PET Film (Premium Quality) |

| RIP software | Maintop/Photoprint |

| Dryer size | 850*650*600mm |

| Dryer weight | 45kg |

| Type | Inkjet Printer |

| Applicable Industries | Garment Shops, Home Use, Printing Shops, Advertising Company |

| After Warranty Service | Video technical support, Online support |

| Local Service Location | Egypt, Turkey, Italy, Pakistan, Chile, UAE, Colombia, Algeria |

| Showroom Location | Egypt, Turkey, Italy, Spain, Romania, Australia |

| Condition | New |

| Automatic Grade | Automatic |

| Color & Page | Multicolor |

| Warranty | 1 Year |

| After-sales Service Provided | Online support, Video technical support |

| Ink Type | Pigment Ink |

| Key Selling Points | High Productivity |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Motor, PLC, Gear |

| Place of Origin | Henan,China |

| Plate Type | DTF Printer |

| Usage | Cloths Printer, film printer |

| Voltage | 110v-220v |

| Dimensions(L*W*H) | 900*470 *500mm |

| Weight | 49kg |

| Certification | CE |

| Print Dimension | 30mm |

| Marketing Type | Hot Product 2021 |

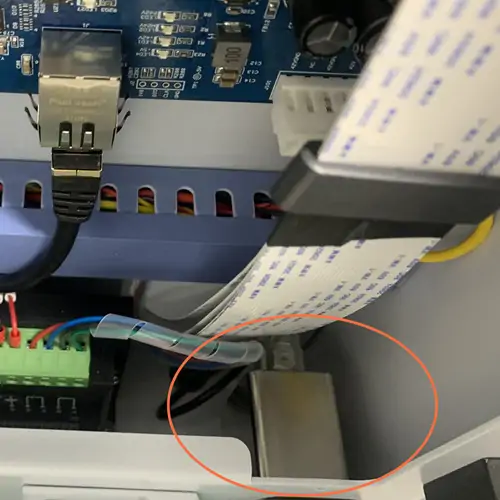

TODOjet A3 DTF Pro Printer Advantages

1.There are filters in the switch to filter clutter and ensure signal output. Generally, manufacturers only have switches.

2.The front and rear heating of the machine is equipped with 2 independent thermostats, which is easy to control. It is generally set to 40-45 degrees before leaving the factory. The pre-heating is to dry the ink of the film after printing a little, and the post-heating is to simply dry the material before printing to dehumidify and ensure better printing color and pigment adhesion.

3.There is a shaft under the fuselage, which functions as follows:

(1) Make the film close and then heated to ensure better dehumidification and drying effect;

(2) Make the paper-out device better sense the film.

4.The machine supports 110V/220V voltage and does not need a transformer for customers who require 110V.

Packaging Details