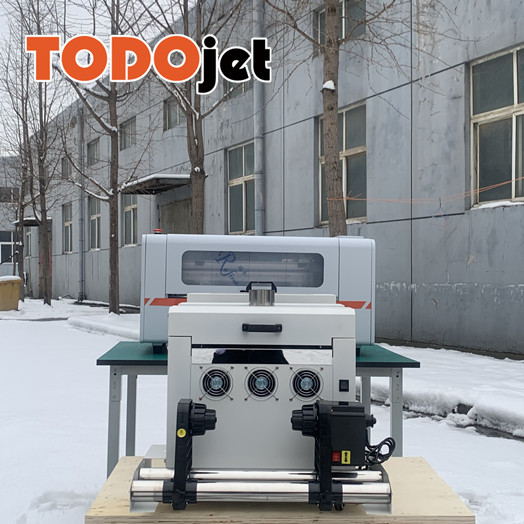

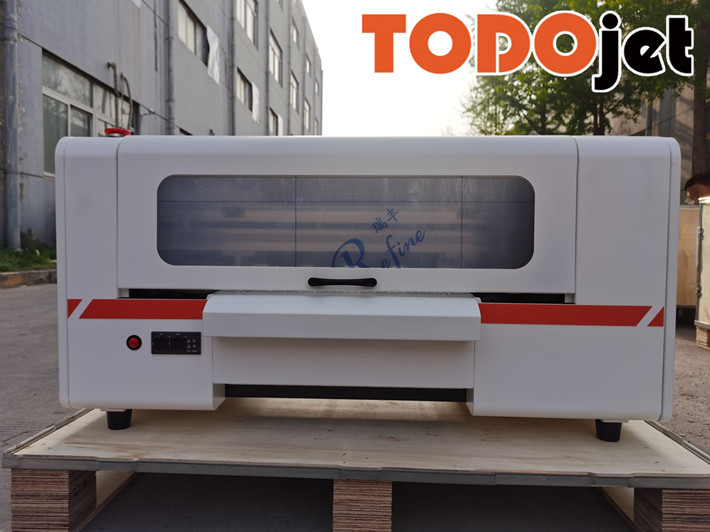

Digital DTF Printer 60cm A3 PET Film T-shirt DTF Printing Machine Powder Shaker Machine

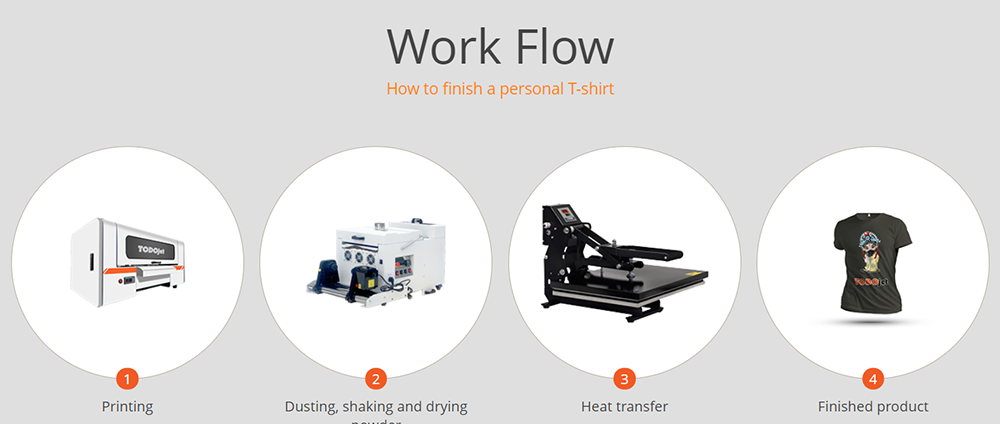

DTF is an exciting innovation to garment field that cannot be ignored. If you have shied away from DTG printing in the past because of the pre-treatment process required when using white ink or you are tired for making plate for screen printing, DTF breaks this cycle and requires no pre-treatment but still offers the soft hand touching and good water fastness .

Specifications

| Model | DTF-6002E | DTF-6004E |

| Print head | 2-i3200A1 | 4-i3200A1 |

| Print speed | 4 pass:12 sqm/h

6 pass:8 sqm/h |

4 pass:22 sqm/h

6 pass:8 sqm/h |

| Print width | 600mm | |

| Machine size | 1737*750*1390mm | |

| Packing size | 1870*880*720mm | |

| Heating system | Pre-heater/rear-heater as standard

Infrared&fan drying system as option |

|

| RIP software | Maintop(standard)/Photoprint(option) | |

Process Flow

Technical Details

1.Double or four originial Epson print heads to achive high quality outcome.

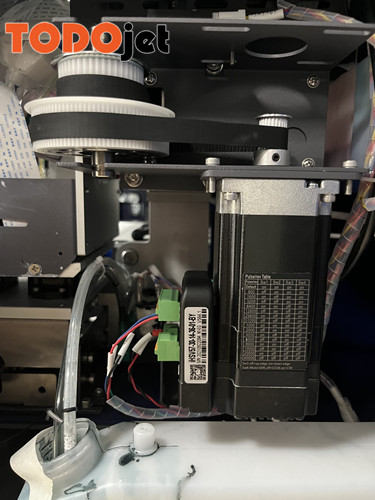

2.Hoson main board offers nice interactive performance with computer software which is easy to operate. Highly-integrated power supply board, good stability, neat routing.

3. Servo motor is almost the same size of industrial use and more stable.

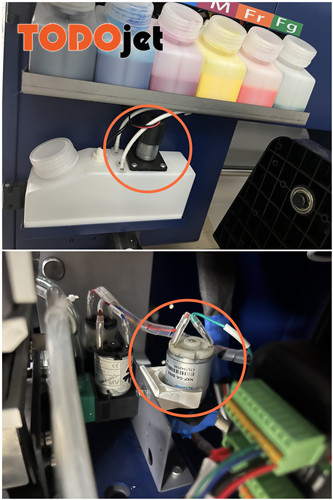

4.White ink stirring-and-circulating system prevents nozzle clogging and low white ink density caused by white ink precipitation.

5. Lack of paper and lack of ink alarm.