6 types of coating Primer of UV printer Instructions and storage matters

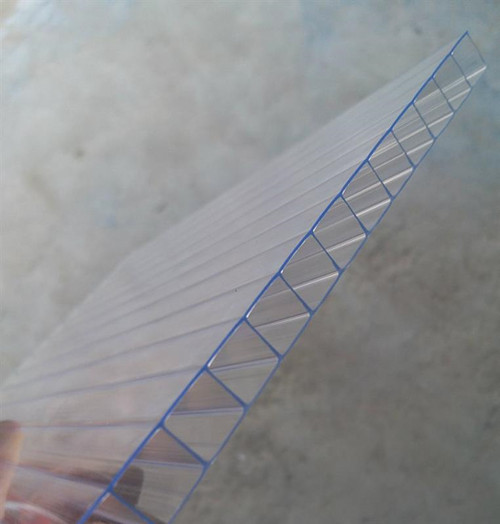

Suitable for plexiglass, tempered glass, glazed tile, crystal and other glass materials that require special treatment. Currently there are two types of quick-drying coating and baking. The former can be printed after standing for 10 minutes and the latter needs to be baked in the oven before printing the pattern.

Suitable for aluminum, copper plate, tinplate, aluminum alloy and other materials, there are two kinds of transparent and white, need to be used on the finished product, can not be used before stamping, injection molding, otherwise the effect will be greatly reduced.

Instructions:

3.The irritating odor of the coating is generally relatively large. It can be equipped with masks and disposable gloves during operation;

4.Different types of coatings correspond to different materials. Do not use one coating to adapt to other materials.

Preservation of the coating:

3.Do not press other materials on it