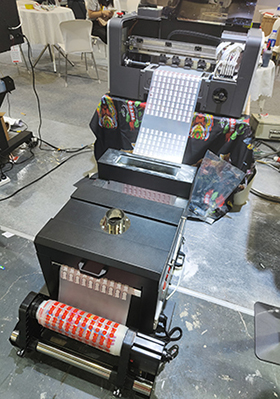

60CM crystal label UV DTF printer automatic tea can label printing laminating machine

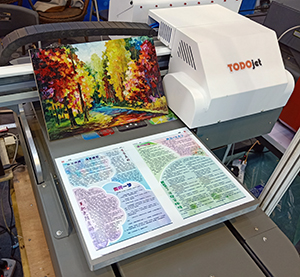

ALL MEMS (Micro-Electro-Mechanical Systems) Manufacturing Process

The use of thin-film piezoelectric elements enables high-precision print hole alignment (600npi/2 rows)

Enables compact, fast and high quality printhead

Normal use after 106 billion cycles of piezoelectric endurance

High precision processing technology, excellent durability

High resolution, smooth color transition, high saturation, fine image quality

ALL MEMS (Micro-Electro-Mechanical Systems) Manufacturing Process

The use of thin-film piezoelectric elements enables high-precision print hole alignment (600npi/2 rows)

Enables compact, fast and high quality printhead

Normal use after 106 billion cycles of piezoelectric endurance

High precision processing technology, excellent durability

High resolution, smooth color transition, high saturation, fine image quality

1.All aluminum suction platform

Even and stable air suction, so that the material is better adsorbed to the platform to ensure the flatness of the material and improve the smoothness of paper feeding

2.High quality drag chain

Can greatly reduce the wear and tear of the harness, prolong the service life of the harness, and increase the stability of printing

3.High precision guide rail

Adopt China Taiwan on the silver linear guide, smooth and noiseless, with the pressure paper wheel to ensure the accuracy and stability of the printing pattern.

4.Servo Motor Mode

Provide the best control on the X-axis to ensure the accuracy of mechanical transmission, lasting and durable

UV-F604 UV DTF Printer

Can be applied to a variety of material surfaces regardless of material restrictions