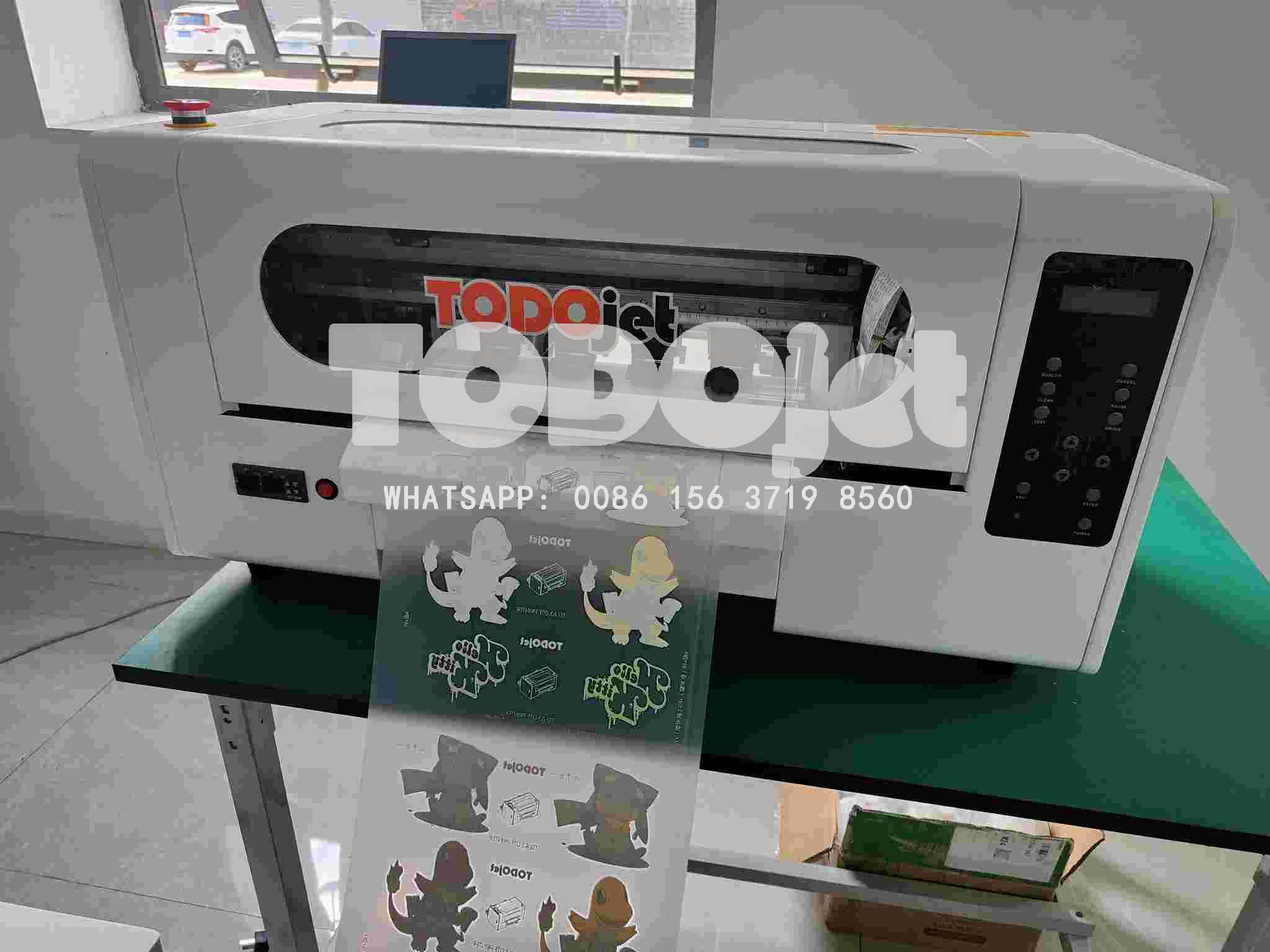

60cm Dual I3200 Head DTF Inkjet Printing Pet Film Printer Machine A1 DTF Printer For T-shirt

1. Before printing, clean the dirt and dust on the printing platform area and the surface of the printing medium to prevent the electrostatic characteristics of the printing process from attracting dust on the surface of the nozzle, causing the nozzle hole to be blocked.

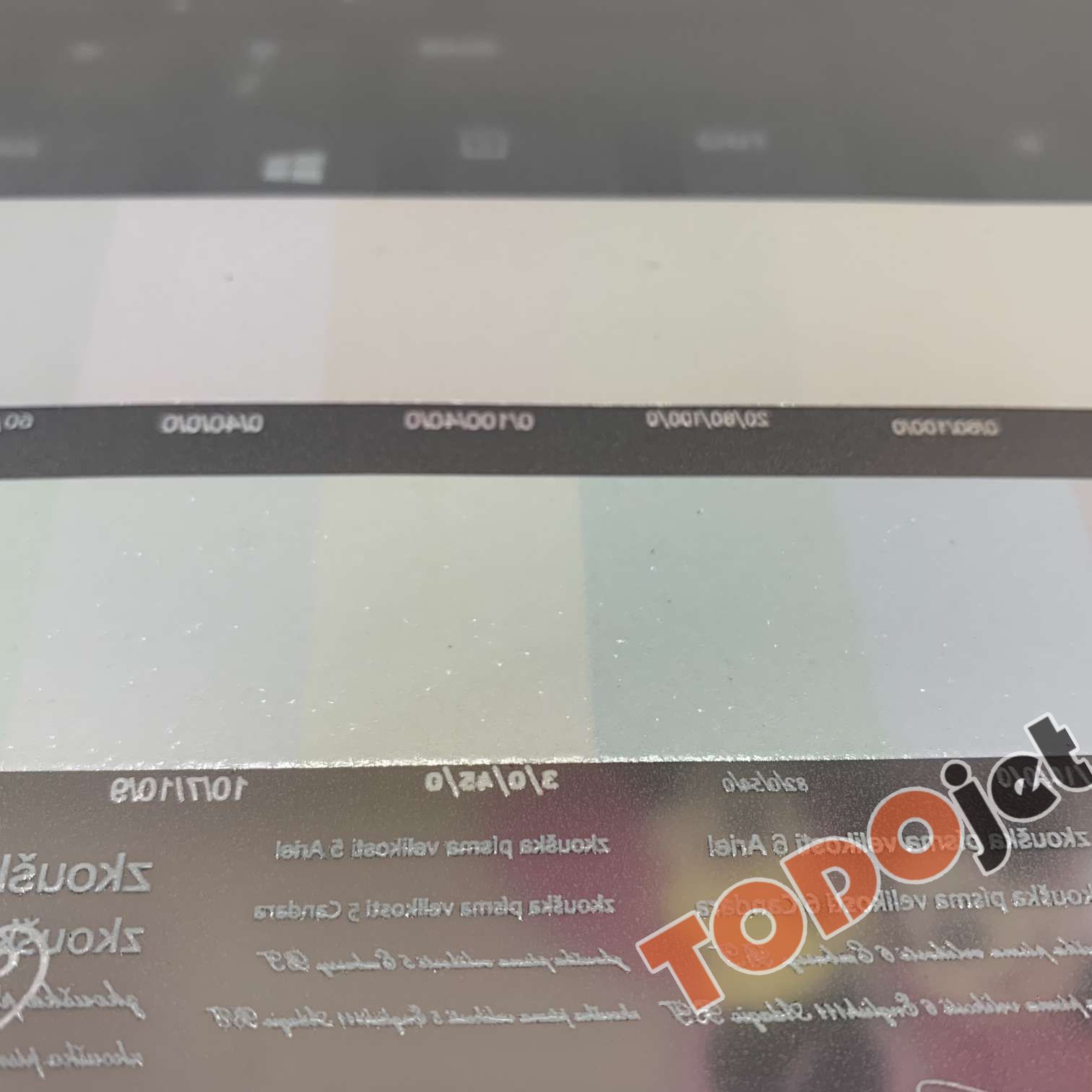

2. After starting up and before shutting down, print the nozzle test strip to check the status of the nozzle. If there is a blockage or oblique spray, it should be cleaned in time.

1. Before printing, clean the dirt and dust on the printing platform area and the surface of the printing medium to prevent the electrostatic characteristics of the printing process from attracting dust on the surface of the nozzle, causing the nozzle hole to be blocked.

2. After starting up and before shutting down, print the nozzle test strip to check the status of the nozzle. If there is a blockage or oblique spray, it should be cleaned in time.

3. During the printing process, every 2-5 hours, use a special cleaning solution to clean the residual ink on the surface of the nozzle to prevent the ink on the surface of the nozzle from solidifying for a long time and block the nozzle holes.

4. During the printing process, avoid that some nozzles do not ink for a long time. It is recommended to add 6 color bars on both sides of the image without affecting the picture, so as to prevent the nozzles from being blocked due to no ink for a certain color for a long time.

5. During the printing process, it is found that the nozzle has broken ink or oblique spraying. It should be suspended in time and cleaned.

6. At the end of the daily printing, the ink remaining on the surface of the print head and around the bottom plate of the print head must be cleaned with a special cleaning solution, and a new, clean non-woven fabric should be dipped in the cleaning solution on the surface of the print head, and the entire spray car cover should be covered Dust hood.