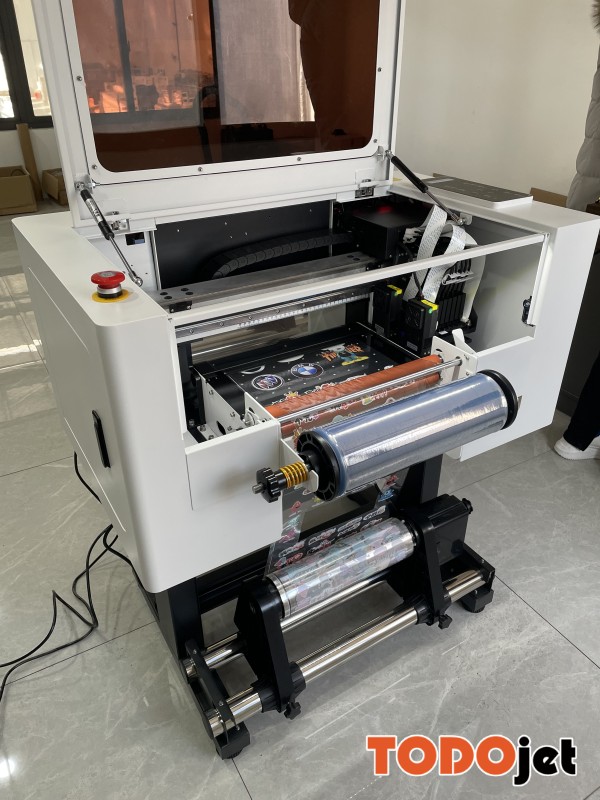

A3 Size 30cm wide UV DTF Printer – UV-S30 New Product with 3*Epson l1600 Heads and Vacuum Platform

This feature is essential for ensuring high-quality printed materials. The suction platform, constructed from aluminum alloy with honeycomb holes, creates an optimal environment for precise substrate placement. The platform’s quality is defined by its load-bearing capacity, flatness, and adsorption efficiency.

This feature is essential for ensuring high-quality printed materials. The suction platform, constructed from aluminum alloy with honeycomb holes, creates an optimal environment for precise substrate placement. The platform’s quality is defined by its load-bearing capacity, flatness, and adsorption efficiency.

The AGP self-developed UV DTF printer (crystal label printer) features a compact design, user-friendly interface, and easy operation, making it an ideal choice for DIY small shop businesses.

| Model | UV-S30 |

| Printhead | 3*Epson l1600 |

| Printing Color | CMYK+W+V |

| Printing Speed | 6PASS 7m²/h 8PASS 5m²/h |

| Printing Size | 300mm |

| RIP Software | Riin/Flexiprint/Cadlink/Maintop |

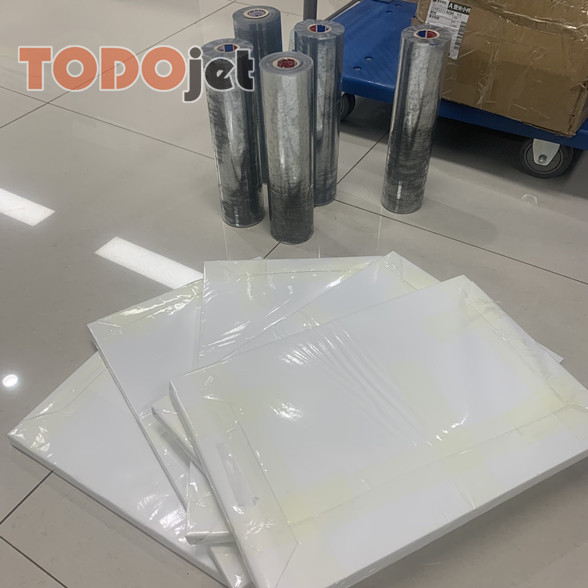

| Printing Media | UV AB film |

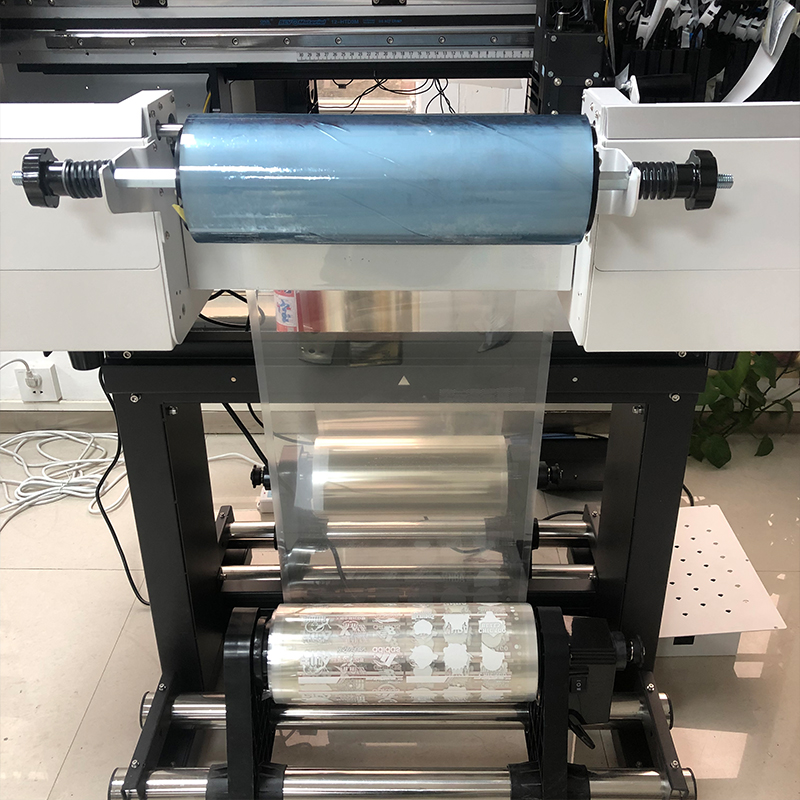

| Lamination | Integrated automatic laminator |

| Ink curing | LED curing |

| Power Supply | 110V/220V 50-60HZ |

| Sleeping:40W

Standby:140W Working:400W |

|

| Work Environment | Temperature:18°C-26°C humidity:35%-70% |

| Dimension | 1170*962*1218mm |

3 Big Steps

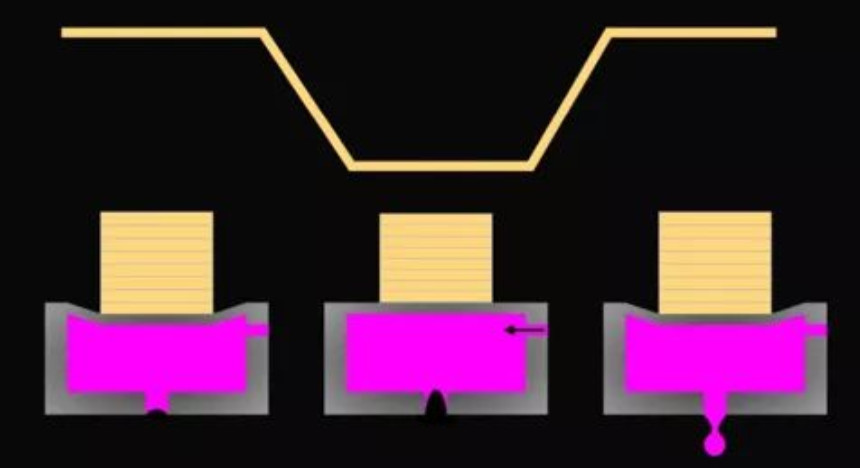

Printing Step UV DTF is a decorative process that involves printing patterns and trademarks on special PP release paper in layers of glue, white ink, and varnish. This is then covered with a transfer film. The transfer film is used to lift the pattern and attach it to the surface of the object.

Using UV DTF is very simple and requires no special equipment. The process involves:

- Separating the pattern from the base film.

- Transferring the film to the surface of the object.

- Pressing firmly once and then peeling off the surface film, leaving the design beautifully attached.