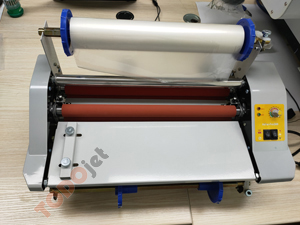

A3 size powder shake machine for our A3 DTF Printer with high quality

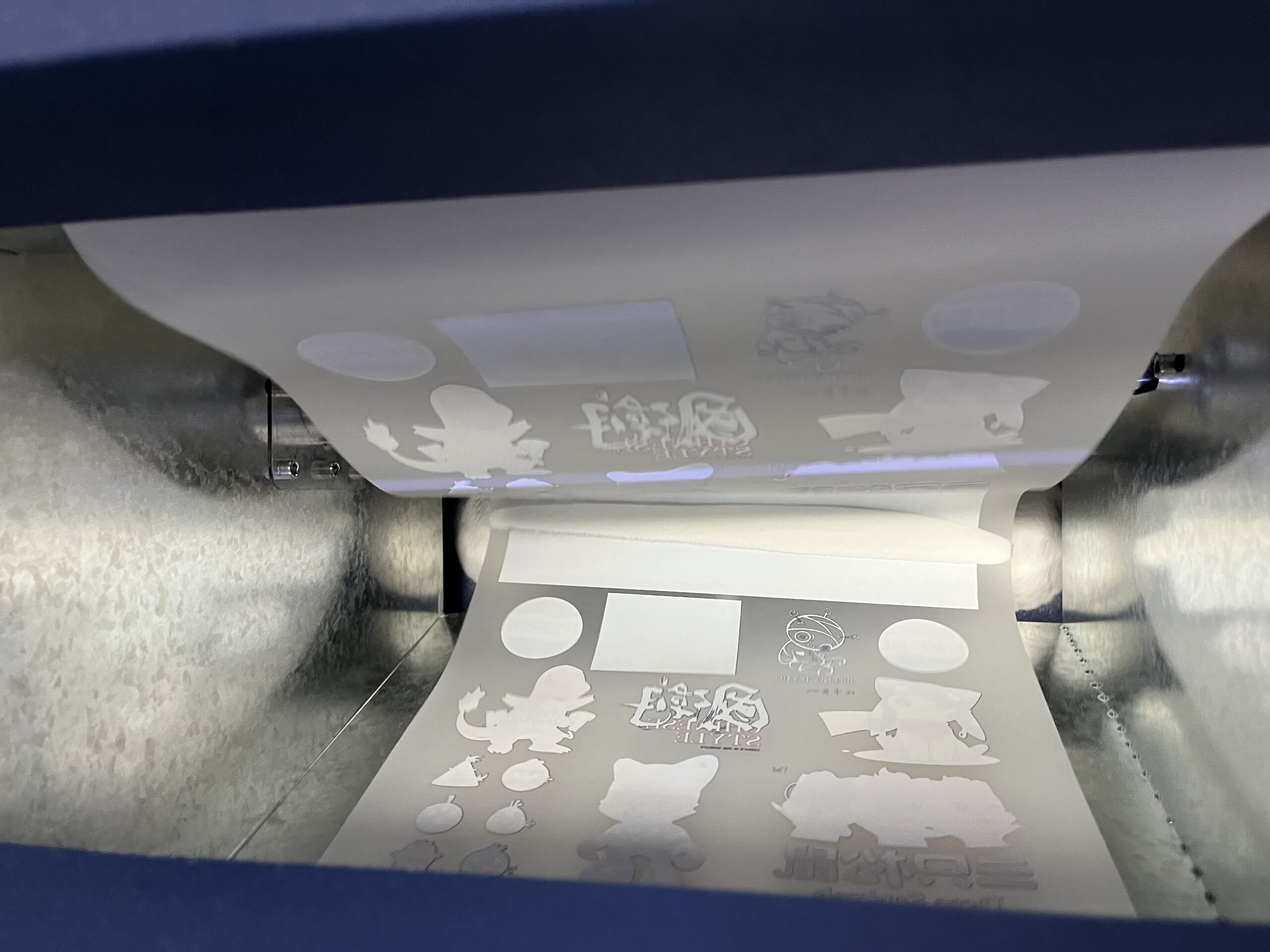

Using the shake powder could consider these procedures.

Dusting.

1.What is the powder sprinkled with?Hot melt powder, when the heat is sticky, after the formation of glue coating;

2.Why?Stick hot melt stick to the dry ink to help eventually form the coating;

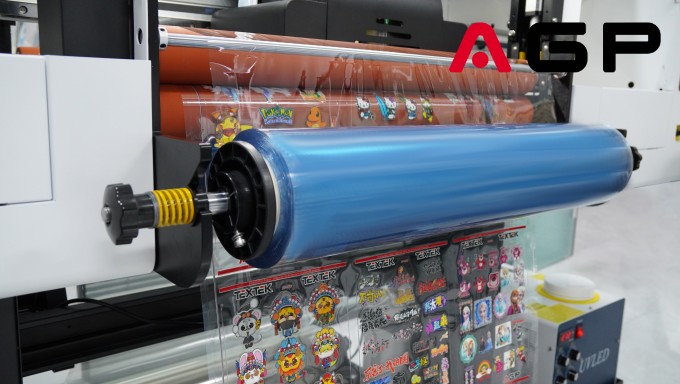

3.How to sprinkle, sprinkle how fast?Can adjust the knob on the shake powder machine;

4.How much?The powder is about 2-3cm thick to stop sprinkling the powder.

Shaking.

1.Why shake powder?Shake off the excess powder on the ink and film adhesion, so that the powder is thin and evenly attached to the ink.

2.Shake powder speed.Depending on the situation, the knob on the condition machine, about 2-3 gear ok.

Drying.

1.Why drying?Melt the hot melt powder to create a reprint pattern coating;.

2.How long will it bake?Undefinite, depending on the specific situation, mainly to ensure that the pattern feels no powder, hot melt powder all melted into coating.

3.Temperature? 90-130 ° C is ok.

The process of using shake powder:

Dusting.

1.What is the powder sprinkled with?Hot melt powder, when the heat is sticky, after the formation of glue coating;

2.Why?Stick hot melt stick to the dry ink to help eventually form the coating;

3.How to sprinkle, sprinkle how fast?Can adjust the knob on the shake powder machine;

4.How much?The powder is about 2-3cm thick to stop sprinkling the powder.

Shaking.

1.Why shake powder?Shake off the excess powder on the ink and film adhesion, so that the powder is thin and evenly attached to the ink.

2.Shake powder speed.Depending on the situation, the knob on the condition machine, about 2-3 gear ok.

Drying.

1.Why drying?Melt the hot melt powder to create a reprint pattern coating;.

2.How long will it bake?Undefinite, depending on the specific situation, mainly to ensure that the pattern feels no powder, hot melt powder all melted into coating.

3.Temperature? 90-130 ° C is ok.

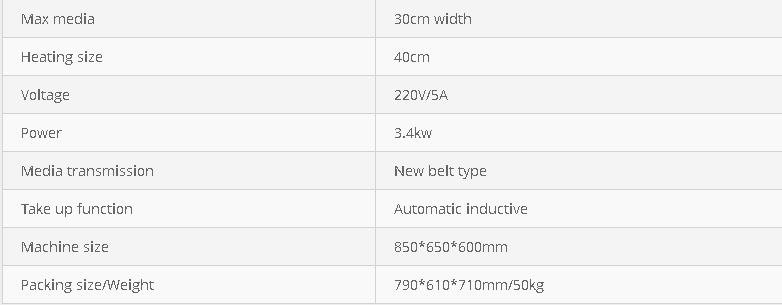

The information of this machine: