AB film UV DTF Transfer Direct Printing With UV DTF Printer

UV printing is one of the most flexible and exciting print processes ever created, and its uses are almost limitless. For regular object, UV Printing is so convenient. But for irregular object, there are some problems, the AB film solution is suitable for these irregular object and you can also develop a new market of label printing industry. Its just expand the application of UV flatbed printer.

1.UV AB Film material is waterproof and high temperature resistant, wear-resistant and scratch-resistant for daily use, bright color and clear details.

2. Attention:

Please note that this technology required varnish printing, and its better use hard or neutral ink.

Printing on film A first (which with glue), then laminating with film B and lamining temperature is 80 degree (laminate the mat side of film B with glue side of film A)

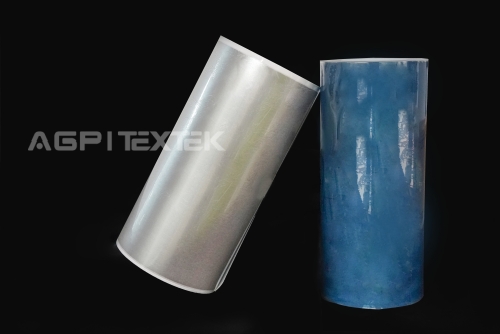

3.A+B Film Instructions:

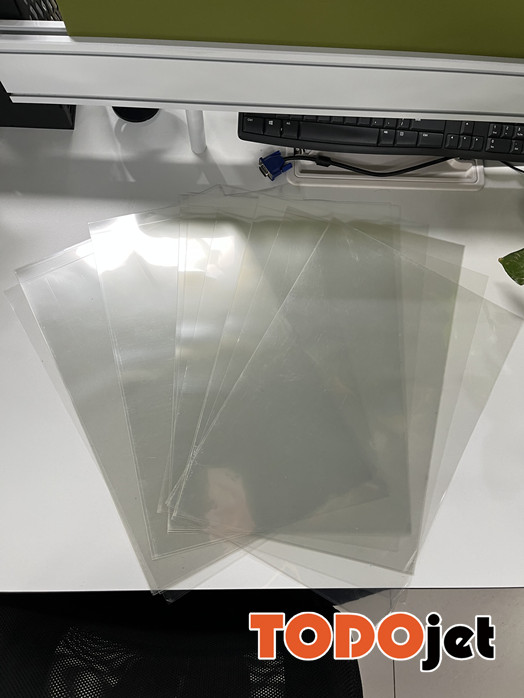

(1)Film A is the printing side, tear off the protective paper, and print with the adhesive side facing up. The printing sequence is: white ink-color ink-varnish;

(2)The B film is hung on the support of the laminator. When laminating, the matte surface must be attached to the glue surface, otherwise it could not be take off. The film temperature is 80 degrees, the slower the better.