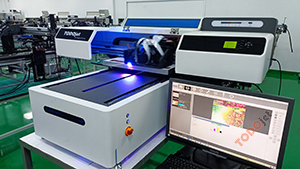

Many people are asking, what is the difference between the height of the product that the UV printer cannot print?

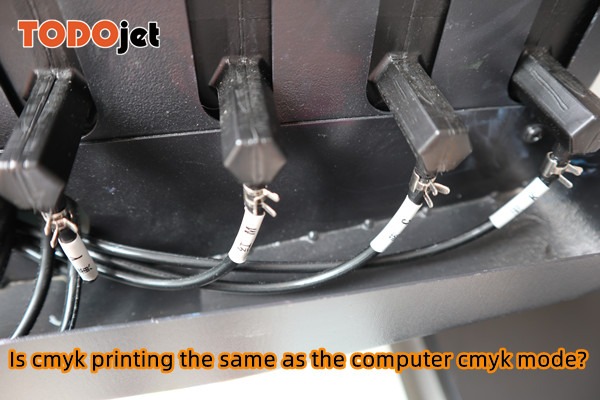

UV printers that print high drop, also known as UV high jets. Under normal circumstances, the maximum height difference of the existing equipment can reach about 15mm, but the height difference also brings a certain burden to the print head itself. Whether it is an industrialized Ricoh nozzle or an inexpensive and easy-to-use Epson nozzle, it is a piezoelectric nozzle. The core principle of achieving high drop is to increase the voltage to the print head to make it eject ink faster. Each print head has its optimal voltage environment. Forcible pressure will bring additional burden to the print head. This is why the high drop will inevitably reduce the service life of the print head.

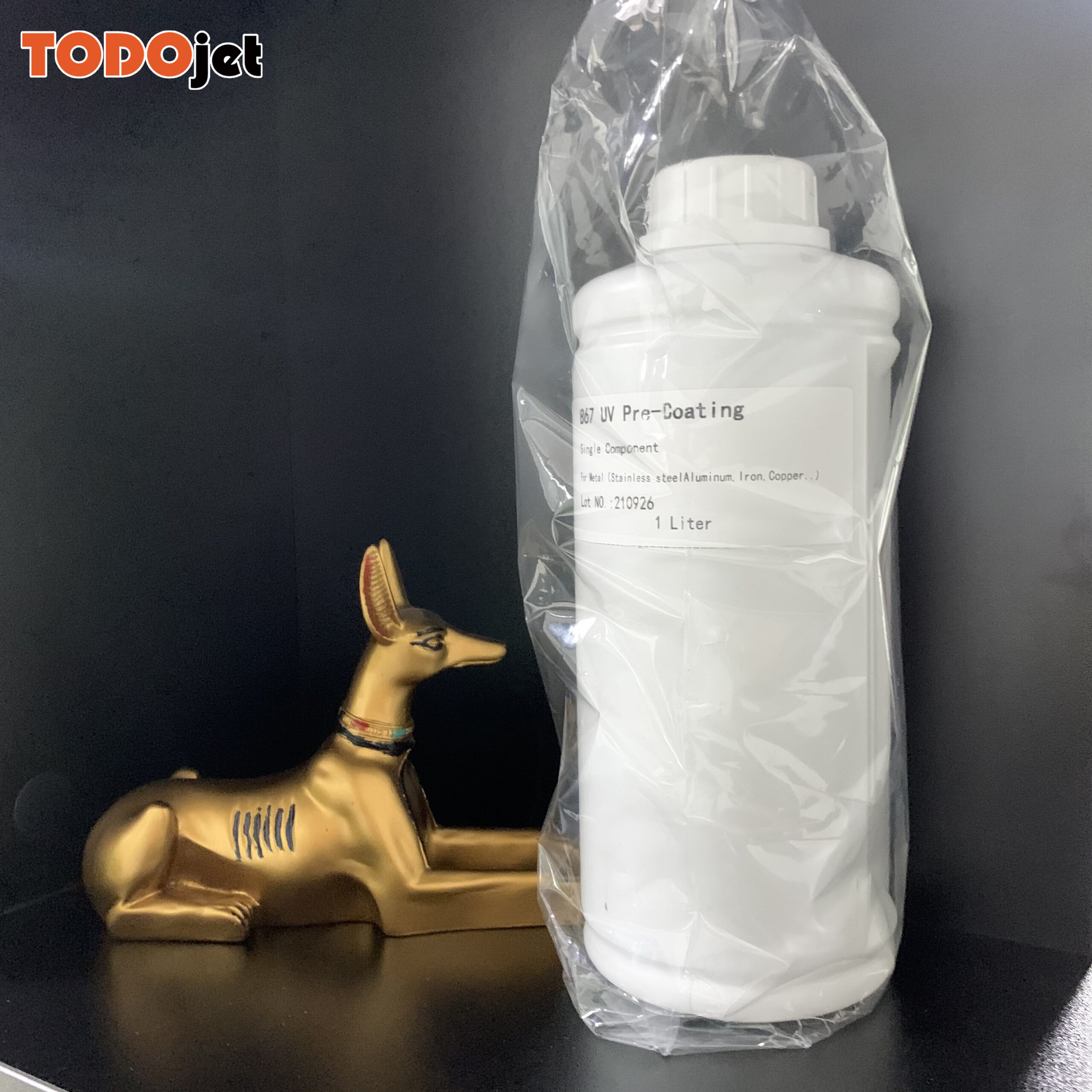

Therefore, choosing a UV printer with a high drop must weigh the pros and cons. In addition, a good UV printer must use good accessories, and everyone must pay more attention when making choices.

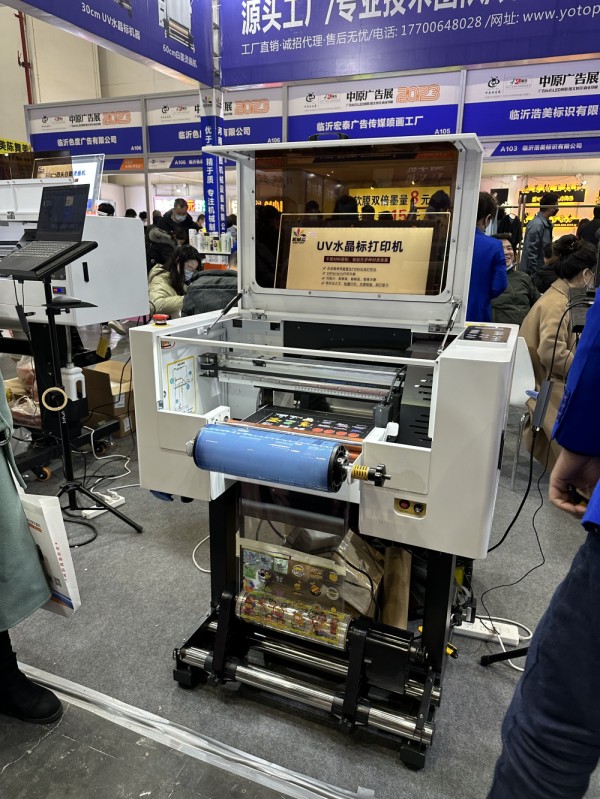

However, the high drop has also brought many benefits to the UV printing industry. Previously, the heads of children’s doll toys, sports shoes, and bottles that were not cylinder-shaped could not be printed, which can basically be achieved now. This not only broadens the scope of use of UV printing equipment, but also facilitates many customers.

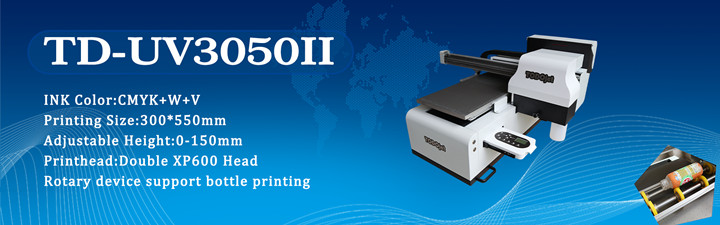

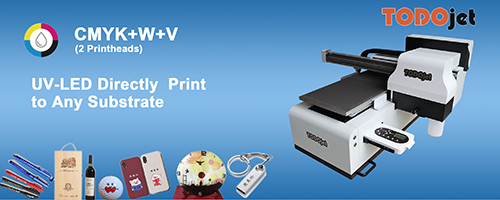

| Model | TD-UV6090 |

| Print head | 2pcs Epson i3200/ 3pcs Epson XP600 |

| Print size | 610*910mm |

| Max print height | 20cm |

| RIP software | Photoprint |

| Max resolution | 720*1440dpi |

| Ink type | UV ink |

| Print color | CMYK+W/ CMYKLcLm+W+V |

| Operating environment | 20-30℃ 35-65RH |

| Voltage | 110V-220V |

| Print speed | 720*720dpi 12sqm/h, 720*1080dpi 10sqm/h, 720*1440dpi 8sqm/h |

| Machine size/net weight | 1400*1710*780mm/220kg |

| Packing size/gross weight | 1550*1860*980mm/360kg |

| Print materials | Acrylic, glass, plastic, pvc, wood, metal, etc |