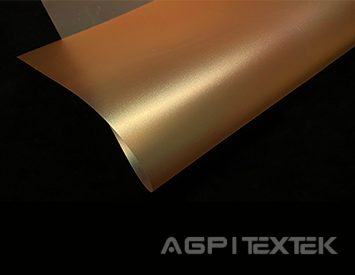

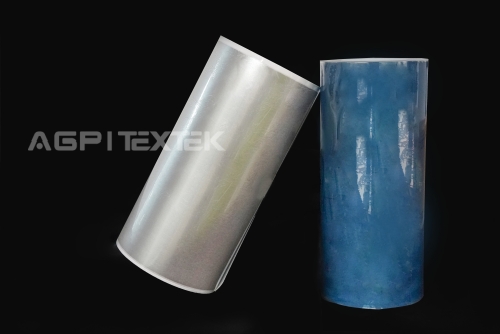

AGP 3D flocking heat transfer lettering film Soft flocking fabric touch Over 50 washes 0.6mm 3D flocking touch

Definition of Flocking Heat Transfer

Flocking heat transfer is a process that uses high-quality flock paper to create patterns with a plush, three-dimensional appearance. The flock feels soft and ranges in height from 0.6 to 1.2mm. This technique includes multi-color flocking and glitter flocking, which are at the forefront of the industry. Flocking heat transfer is widely used in various applications, such as women’s clothing, sportswear, children’s clothing, plush toys, and sweaters.

Definition of Flocking Heat Transfer

Flocking heat transfer is a process that uses high-quality flock paper to create patterns with a plush, three-dimensional appearance. The flock feels soft and ranges in height from 0.6 to 1.2mm. This technique includes multi-color flocking and glitter flocking, which are at the forefront of the industry. Flocking heat transfer is widely used in various applications, such as women’s clothing, sportswear, children’s clothing, plush toys, and sweaters.

Principle of Flocking Heat Transfer

The principle of flocking relies on the physical properties of electric charges, where like charges repel and opposite charges attract. In this process:

- Charging the Flock: The flock is given a negative charge.

- Preparing the Object: The object to be flocked is placed under zero potential or grounding conditions.

- Flocking Process: The negatively charged flock is attracted to the object with a different potential and accelerates vertically towards its surface.

- Adhesion: The object is coated with adhesive, allowing the flock to adhere vertically, creating a plush effect.

Electrostatic flocking leverages the natural characteristics of electric charge to achieve this unique production process.

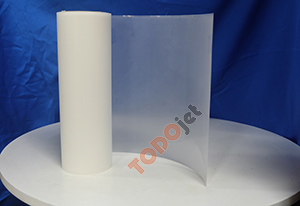

3D flocking heat transfer lettering film

Soft flocking fabric touch,

0.6mm 3D flocking touch,

Various styles and patterns to choose from,

Over 50 washes.

| Category | Details |

| Main Material | PET flocking film |

| Performance Characteristics | Thick plate,Back adhesion, Folding resistance,Wear resistance- Washability, Regular stock of 3 colors, other colors can be customized |

| Appearance Effect | 0.7-0.8mm thick, three-dimensional |

| Technology Characteristics | Easy to engrave,Easy to discharge,Suitable for engraving with a laser marking machine |

| Typical Applications | Clothing, gloves, bags, shoes, socks and hats, sports equipment, masks, household textiles, etc. |

| Packaging Specifications | 40*50cm/sheet |

| Hot Stamping Instructions | Temperature: 155-165℃,Time: 18-28 seconds,Pressure: 4-6KG,Cold tear (tear after complete cooling) |

| Note | This product is not suitable for metal, ceramics, plastics, waterproof cloth, anti-slip cloth, wooden products, etc. |

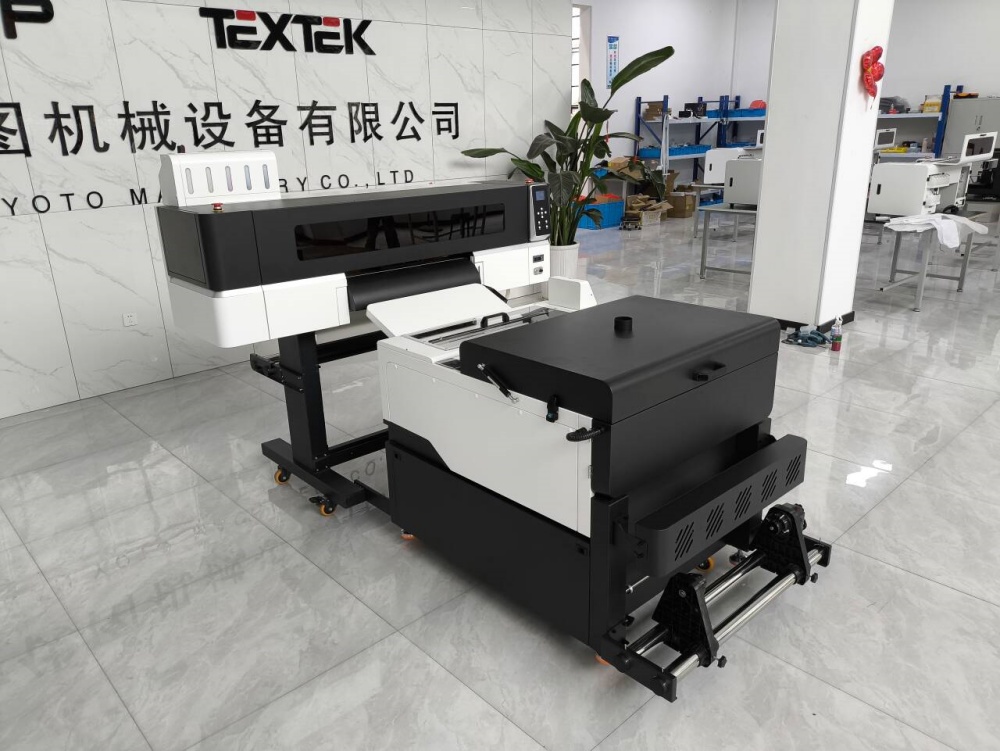

Traditional Flocking Printing Process

- Silk Screen Printing: Special flocking slurry is repeatedly applied to the substrate through a silk screen printing plate.

- Drying: Each layer of slurry must be dried before the next application.

- Thermal Transfer: The fluff on the flocking paper is transferred to the substrate using a thermal transfer machine.

This method is complex, technically demanding, costly, and time-consuming. It is suitable for large-scale production in professional printing factories, making small batches and personalized flocking printing impractical.