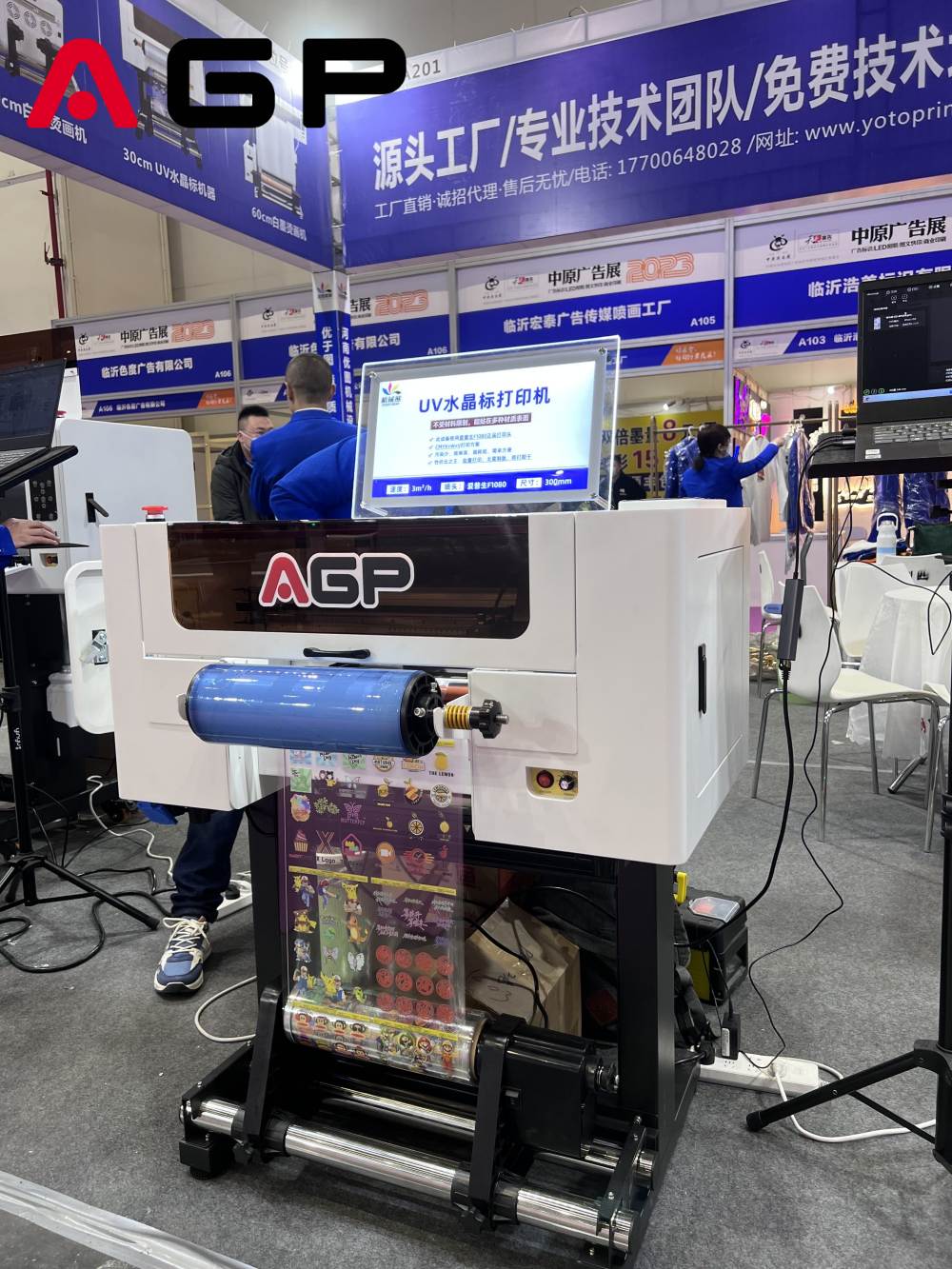

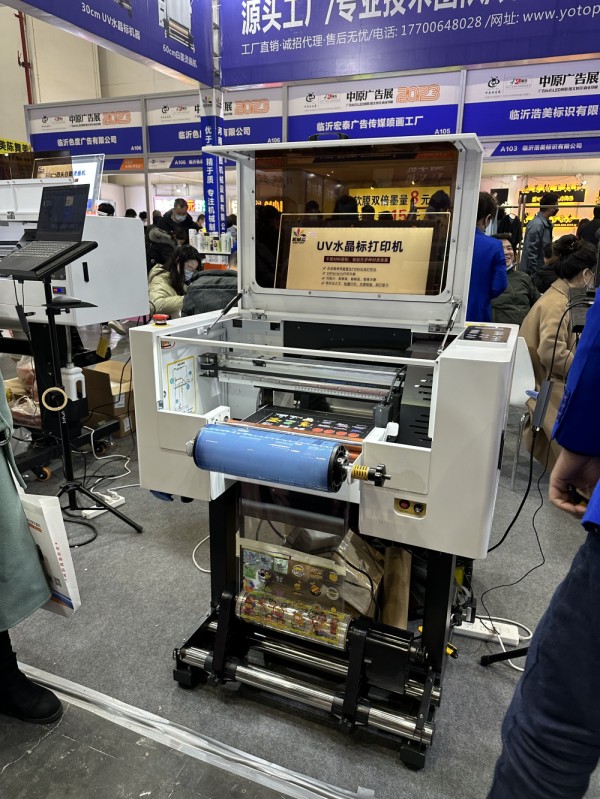

AGP UV DTF printer full set AB film automatic 30CM UV flatbed varnish printer for phone case bottle glass metal sticker

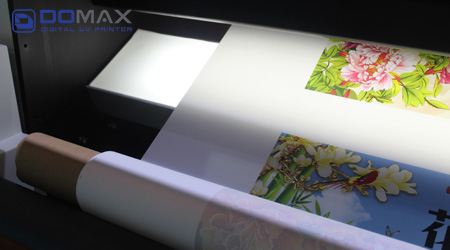

Crystal label, it is first glue, isolation, pattern, hot stamping, varnish layer by layer in a special PP release paper printed into patterns, trademarks, etc., and then covered with transfer film. Then use the transfer film to bring up the pattern and attach it to the surface of the object as a decorative process.

Crystal label, it is first glue, isolation, pattern, hot stamping, varnish layer by layer in a special PP release paper printed into patterns, trademarks, etc., and then covered with transfer film. Then use the transfer film to bring up the pattern and attach it to the surface of the object as a decorative process.

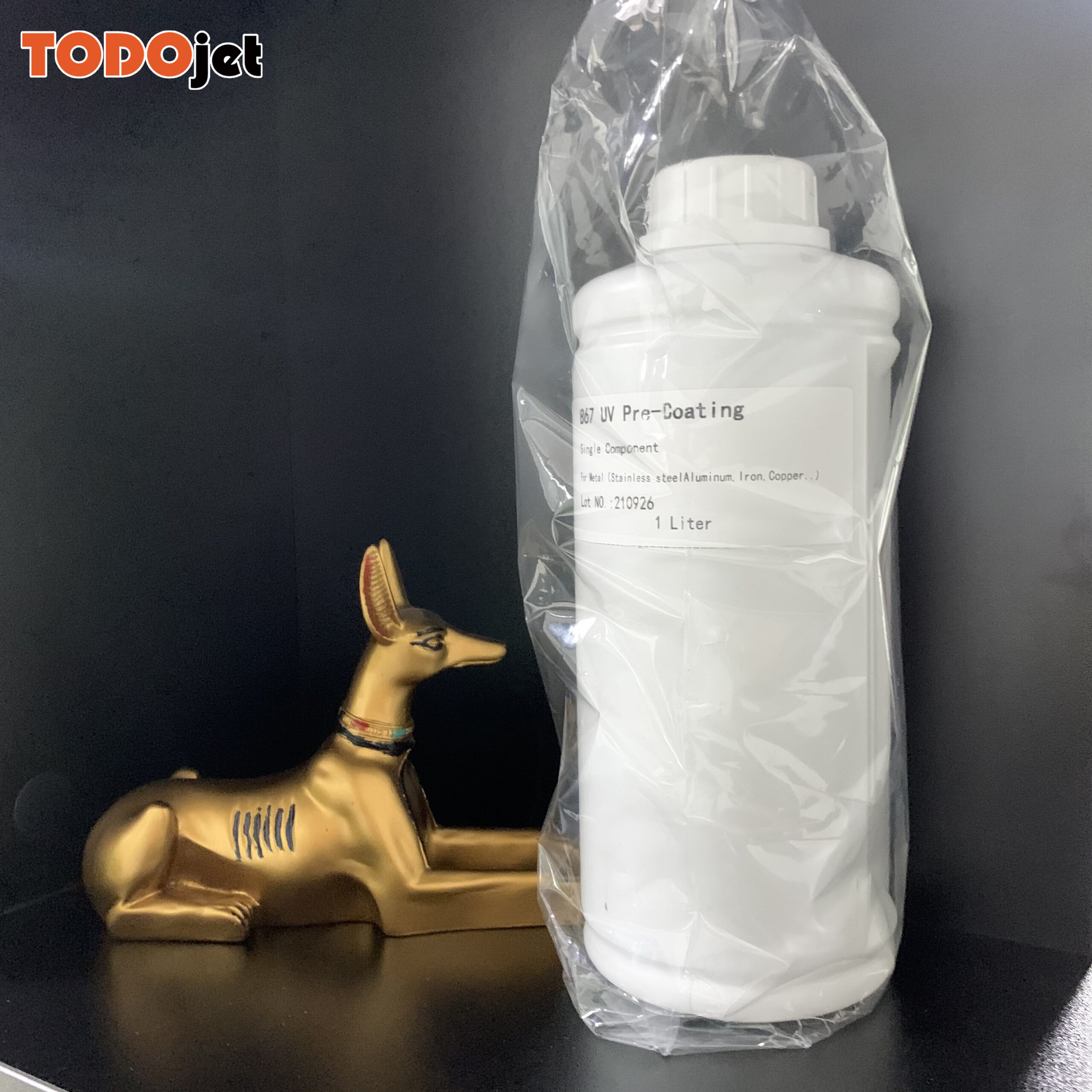

UV printer can achieve a piece of printing, no plate, that is, to play that out, greatly eliminating a variety of tedious operational steps and processes, whether it is LOGO trademark or gradient pattern, “matte mode”, “bright mode, no light oil mode and other modes of effect can be achieved, to meet the needs of many kinds of personalized small batch of custom customers.

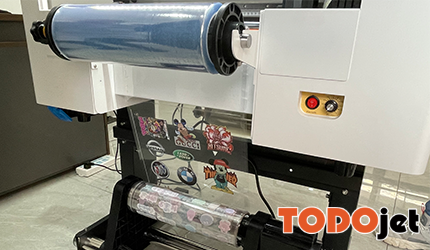

In fact, the equipment is not the hard part of making crystal labels, the backing paper is.

The backing paper is the key to determine whether the crystal label can be transferred completely and easily. A good quality backing paper can firmly stick to the pattern, but it is very easy to separate the two, even if the text is very fine strokes, it can be easily transferred to the transfer paper.

And chemically stable, when the temperature and humidity of the surrounding environment changes, the length and width of the backing paper remains unchanged, so as to avoid wrinkling and deformation of the backing paper, the impact of the pattern.

Crystal label backing paper on the market is not uniform, how to choose a good price, strong adhesion backing paper, is the key to advertising people can print the perfect pattern.