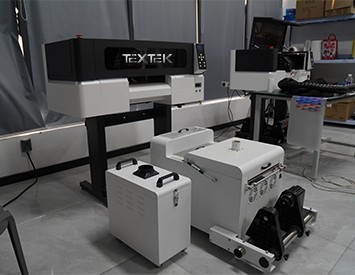

China A3 DTF printer supplier with xp600 printhead for T-shirt printing

Probably many people have already tried on the possibility of direct printing on dark T-shirts,they mostly known to choose DTG printer and screen printing can reach their demand, but the price barrier makes most of those who want to do it nervously aside.

For these two solution, it’s good when there is a flow of orders for large volumes, you can, in principle, recoup investments. But this is far from always the case; in most regions, orders are limited by very modest regional demand.

Then, TODOjet offer you a economicable solution to make customized T-shirt and make benefit. We use Brand new DTF printing technology, suitable for any fabric. No MOQ, printing fast, low printing cost, and cheap start cost.

DTF technology advantages:

1) Adequate investment for the start.

2) The ink for this technology is activated by heating with a polymer, they do not need primary polymerization in the material. Therefore, they clog less steam generator and have a higher shelf life of 2 years, instead of half a year for textile ones.

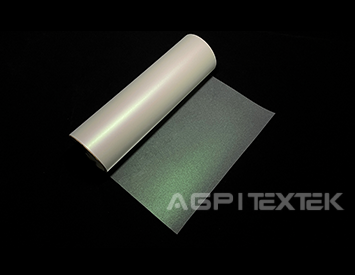

3) The polymer backing eliminates the problem with different types of fabric, remember that with direct printing you have to make several passes with white, which falls into the fabric, like water in sand at low tide.

4) There is no need to prime products before transferring images.

5) The technology is convenient when you need a lot of small logos. They are printed in one pass on a sheet, and then transferred to products in the flow. In a textile printer, just stacking a T-shirt for each print takes a lot of time. Considering that pressing after direct printing is also necessary.

6) More stable color on any media.

7) The result is similar to silk-screen printing with plastisol paints. Partially, the structure of the tissue remains. The image is stretched and deformed.

8) Image durability is slightly higher than direct printing on fabric.