Daily Maintenance Tips for UV DTF Printers to Ensure Optimal Performance and Print Quality

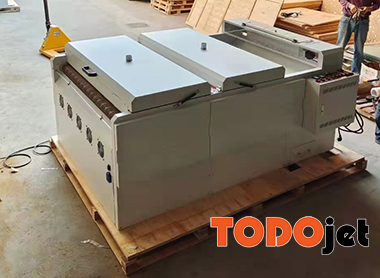

Daily maintenance is essential for keeping your UV DTF printer in top condition and ensuring high-quality prints for custom transfers, personalized merchandise, and other print applications. Proper maintenance helps avoid costly repairs, extends the lifespan of your UV DTF printing machine, and minimizes downtime. Here are some key daily maintenance steps you should incorporate into your routine for optimal print quality and machine performance.

Daily maintenance is essential for keeping your UV DTF printer in top condition and ensuring high-quality prints for custom transfers, personalized merchandise, and other print applications. Proper maintenance helps avoid costly repairs, extends the lifespan of your UV DTF printing machine, and minimizes downtime. Here are some key daily maintenance steps you should incorporate into your routine for optimal print quality and machine performance.

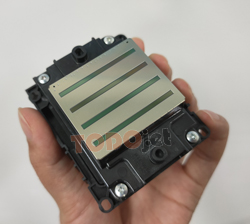

1. Daily Maintenance of the Printhead in Your UV DTF Printer

The printhead is the heart of your UV DTF printer. Regular maintenance of the printhead is crucial to prevent clogging, ensure consistent print quality, and avoid costly repairs.

(1) After Work Each Day:

- Test the printhead: After finishing your printing for the day, perform a quick printhead test. Keep the test ink strip from the day’s print job and compare it with the test strip from the following day. This helps to identify any potential issues early on.

- Return the printhead to the ink pad: Ensure that the printhead is placed above the ink pad overnight to allow the pad to keep the printhead moist. UV DTF ink can dry quickly when exposed to air, leading to clogged nozzles or even permanent damage. This simple step ensures that the printhead is kept in optimal condition for the next day’s print job.

(2) Before Work Each Day:

- Test the printhead: Before starting work in the morning, test the printhead and compare it with the test strip from the previous day. If the ink flow is inconsistent or there are gaps in the strip, clean the printhead until it shows a solid, uninterrupted test strip.

- Clean the printhead if necessary: Perform a cleaning routine if the ink is not flowing evenly. Testing and cleaning the printhead before and after each print run ensures that the printer is ready to produce high-quality prints and minimizes the risk of print defects.

Tip: Regular printhead testing ensures that your UV DTF printer operates at peak performance and prevents issues such as uneven printing, ink wastage, and print quality degradation.

2. Protect Your UV DTF Ink from Light Exposure

UV inks are sensitive to light and can begin to cure or dry out when exposed to it. To maintain optimal ink performance and prevent premature curing, follow these tips:

- Keep ink components out of direct light: Ensure that the ink tank, ink tubes, nozzles, and other ink-related components are kept away from any light sources, both during operation and while the machine is idle.

- Monitor ink condition: Regularly check the ink levels in your UV DTF printer and replace any dried or thickened ink. If you notice that the ink has dried up or is not flowing properly, replace it immediately to avoid print quality issues.

AGP Tip: For small manufacturers with lower production volumes, small capacity inks (e.g., 100ml or 500ml bottles) are ideal. These smaller containers can be used quickly, reducing the risk of the ink drying out due to prolonged exposure to light.

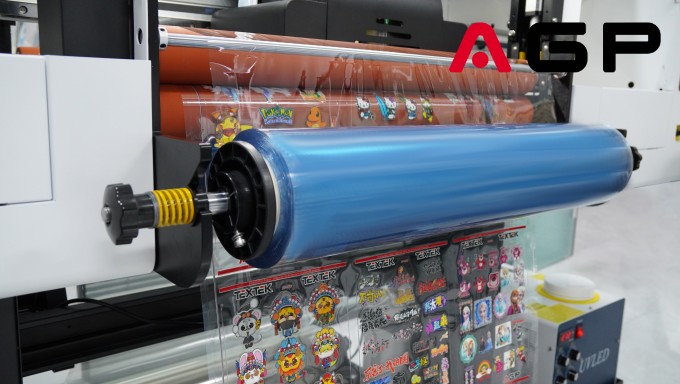

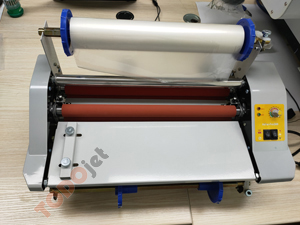

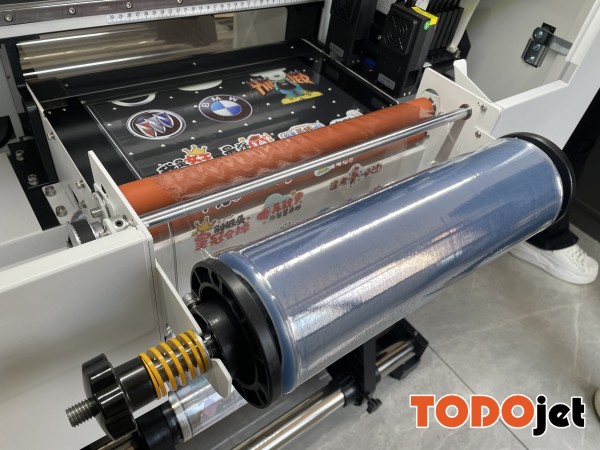

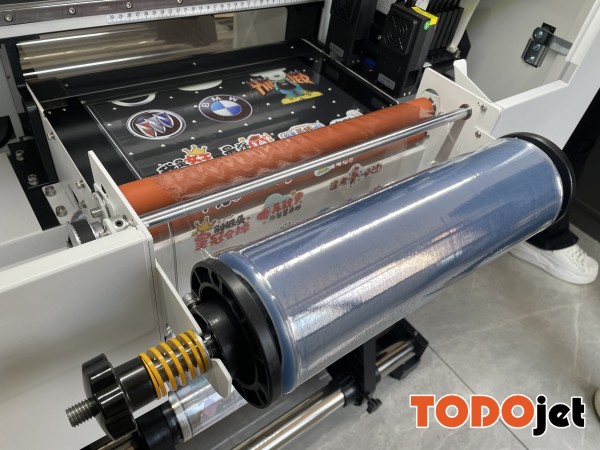

3. Keep the Printing Film Dry and Smooth

The quality of your DTF transfer film plays a significant role in achieving excellent print results. To ensure smooth and consistent prints:

- Maintain a dry working environment: If possible, control the humidity levels in your printing area to prevent moisture from affecting the DTF film.

- Inspect the film before each print: Check the DTF transfer film for any dampness or wrinkles. If the film appears damp or warped, replace it with fresh, dry film to avoid print defects and ensure smooth application of your UV prints.

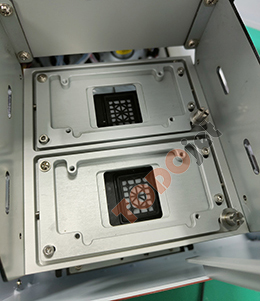

4. Keep Your UV DTF Printer Clean and Tidy

A clean machine is essential for consistent performance. Dust and debris can damage the nozzles, affect print quality, and lead to costly repairs. Here’s how to maintain a clean working environment:

- Clean the printer surface: Before starting your daily printing routine, wipe down the surface of the UV DTF printer to remove any dust or debris that could interfere with its operation.

- Tidy up the workspace: Ensure that the area around the printer is free from dirt, dust, and foreign particles that could potentially damage the machine’s components, especially the printhead and nozzles.

Regular cleaning prevents buildup of unwanted particles that can cause clogs, misprints, and quality issues.

Why Daily Maintenance is Crucial for Your UV DTF Printer

Incorporating daily maintenance routines into your UV DTF printing workflow not only helps extend the lifespan of your DTF printer but also ensures that every print job meets your quality standards. By keeping the printhead clean, preventing ink drying issues, maintaining proper humidity for the transfer film, and ensuring a clean workspace, you reduce the chances of costly repairs and unnecessary downtime.

Regular maintenance also improves print quality, reduces waste, and ensures that your UV DTF printer is ready for high-performance tasks, whether you’re printing custom transfers for T-shirts, mugs, or promotional products.

Conclusion: Maximize Your UV DTF Printer’s Performance with Regular Maintenance

Adopting daily maintenance practices is essential for keeping your UV DTF printer running smoothly and ensuring high-quality prints. By maintaining the printhead, protecting the ink from light exposure, keeping the transfer film dry, and ensuring a clean workspace, you can achieve consistent results and reduce the risk of downtime or print errors. Regular upkeep is an investment in the long-term performance of your UV DTF printing machine, ensuring that you get the best possible results every time.