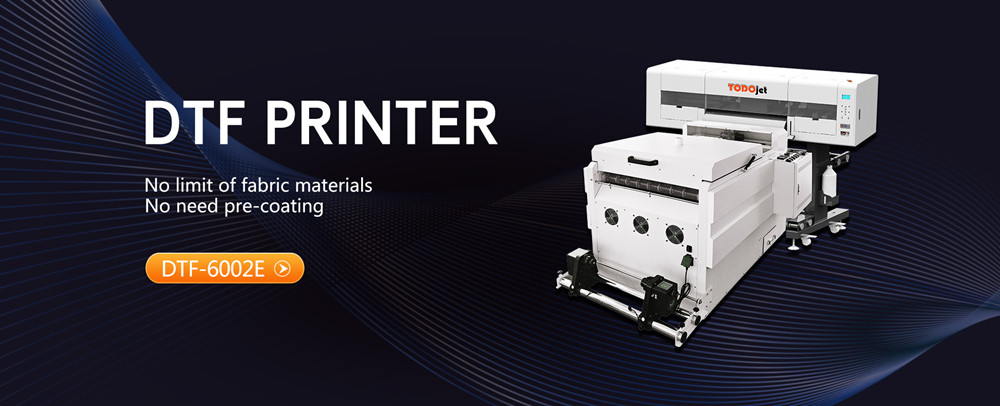

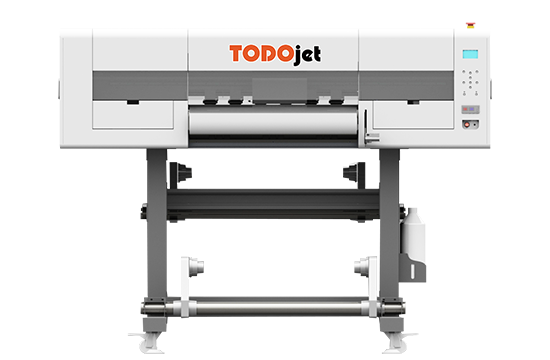

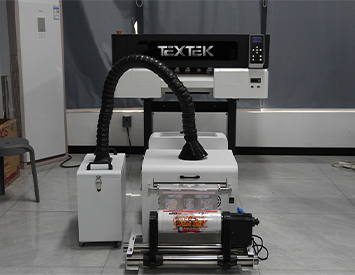

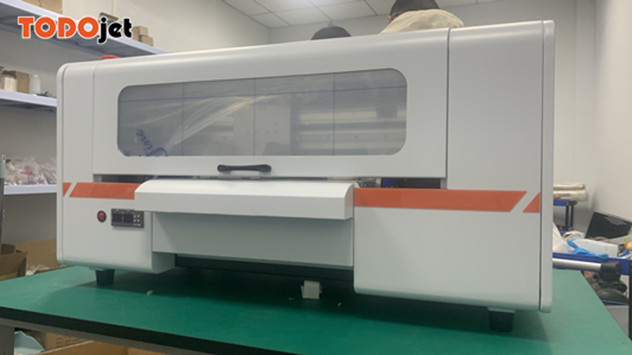

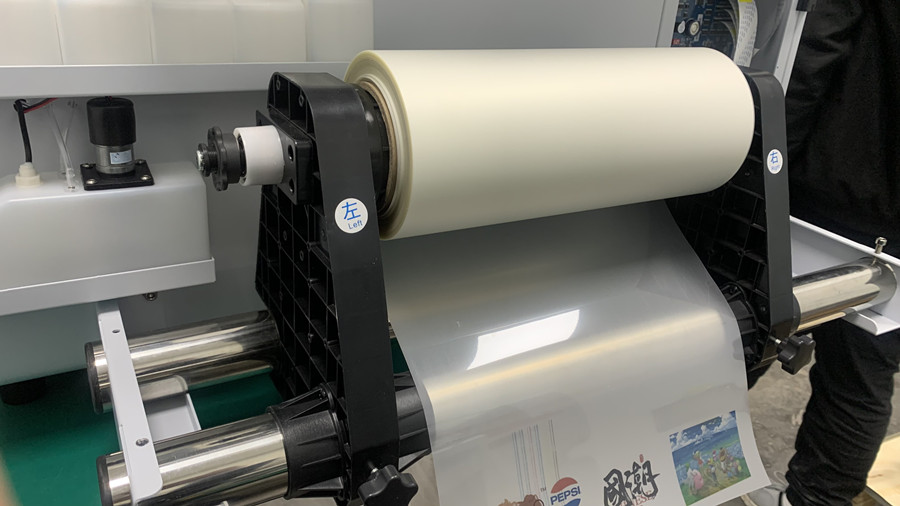

Desktop Plastisol Heat transfer printer dtf pet film printer 60cm dtf printer for t-shirt With Shaker

60CM DTF Printer

No limit of fabric materials

No need pre-coating

CMYK+ White (Fluoresent color for option)

2pcs EPSON i3200-A1 (4 heads for option)

Printing width: 60cm

Printing Speed: 10~15sqm/h

Software: Maintop/Photoprint

Comparison of TODOjet 60CM DTF Pro Printer and Traditional Printing

Offset heat transfer transfer is also known as offset transfer. It is to use a layer of silicon and wax solution coated on the base paper, and then hot melt and liquefy when heated, so that the printing material flux penetrates into the fabric to form the principle of hot melt loose bonding and two printing methods: offset printing and screen printing. The combination of processes produces a product with transfer conditions. Thermal transfer printing is a type in the textile printing industry, and offset transfer printing is an independent production process and unique printing method of thermal transfer printing. It is widely used in cultural shirts, T-shirts, shoes and hats, school bags, luggage, trademarks, etc. It has strong artistic appeal and decoration, and has a unique style. It feels soft, washable, and has a clear and vivid pattern. incomparable.

1.Differences in pattern feel and washability

(1)Offset heat transfer, soft to the touch after hot pressing, skin-friendly and comfortable to wear, stretch-resistant, wash-resistant, dry and wet rubbing fastness up to grade 4, and it will not crack and feel offset after dozens of washes.

(2)Traditional heat transfer has a cold and hard texture, and it is not breathable to wear. It looks like a hard piece to the touch, and the adhesion is not strong. After washing several times, it will crack and fall off, and there will be a sticky glue feeling.

2. Differences in health and environmental protection

(1)Offset heat transfer, printing with water-based environmentally friendly ink, no waste and no pollution during the printing process, and the hot melt powder used is also healthy and environmentally friendly.

(2)Traditional heat transfer needs to be covered with film, there is a lot of waste, and glue needs to be used, and the material is general.

3. The requirements for the pattern are different

(1)Offset heat transfer, through software analysis, automatic pattern hollow processing, no matter how small or complex patterns can be printed, no special requirements for color, can be printed at will.

(2)In traditional heat transfer, some very complex and small patterns are difficult to complete with an engraving machine, and there will be some choices in color.

4. Differences between personnel and venues

(1)Offset heat transfer, from printing to finished heat transfer, one person is enough, 2 people can cooperate to see multiple machines, and one machine occupies less than one parking space.

(2)In traditional heat transfer, each machine operates in a decentralized manner, from drawing – printing – laminating – cutting – lettering, at least two or three people are required to complete a complete set of processes, and the area is much larger.