Did you choose the right one? Guide to DTF Transfer Hot Melt Powders

Did you choose the right one? Guide to DTF Transfer Hot Melt Powders

Hot melt powder is the key material in the DTF transfer process. You may be wondering what role it plays in the process. Let’s find out!

Hot melt powder is a white powdery adhesive. It comes in three different grades: coarse powder (80 mesh), medium powder (160 mesh), and fine powder (200 mesh, 250 mesh). Coarse powder is mainly used for flocking transfer, and fine powder is mainly used for DTF transfer. Because it has such great adhesive properties, hot melt powder is often used as a high-quality hot melt adhesive in other industries. It’s very elastic at room temperature, turns into a viscous and fluid state when heated and melted, and solidifies quickly.

Did you choose the right one? Guide to DTF Transfer Hot Melt Powders

Hot melt powder is the key material in the DTF transfer process. You may be wondering what role it plays in the process. Let’s find out!

Hot melt powder is a white powdery adhesive. It comes in three different grades: coarse powder (80 mesh), medium powder (160 mesh), and fine powder (200 mesh, 250 mesh). Coarse powder is mainly used for flocking transfer, and fine powder is mainly used for DTF transfer. Because it has such great adhesive properties, hot melt powder is often used as a high-quality hot melt adhesive in other industries. It’s very elastic at room temperature, turns into a viscous and fluid state when heated and melted, and solidifies quickly.

Its characteristics are:It’s safe for people and good for the environment.

The DTF transfer process is really popular with industry manufacturers. Many manufacturers are looking for ways to choose consumables after buying a DTF printer. There are lots of types of consumables for DTF printers on the market, especially DTF hot melt powder.

The role of hot melt powder in DTF transfer process

1.Enhance adhesion

The main role of hot melt powder is to enhance the adhesion between the pattern and the fabric. When the hot melt powder is heated and melted, it adheres well to the white ink and fabric surface. This means that even after many washes, the pattern remains firmly attached to the fabric.

2.Improved pattern durability

Hot melt powder is more than just an adhesive. It also makes patterns last longer. The hot melt powder forms a strong bond between the pattern and the fabric, which means the pattern won’t flake or peel off during washing or use. This makes the DTF transfer process ideal for frequently used apparel and fabric products.

3.Improve the feel and flexibility of your handiwork

High-quality hot melt powder can form a soft and elastic adhesive layer after melting, which can prevent the pattern from becoming stiff or uncomfortable. If you’re looking for a soft feel and good flexibility in your garments, choosing the right hot melt powder is key.

4. Optimize the heat transfer effect

Using hot melt powder in DTF transfer can also help optimize the final heat transfer effect. It can create a uniform protective film on the surface of the pattern, which makes the pattern clearer and brighter, making it look more vivid and refined.

Should you choose DTF hot melt powder?

DTF hot melt powder might look like just another kind of glue, but it’s actually pretty important. Glue is basically an intermediate that connects two materials. There are lots of different types of glue, most of which come in the form of aqueous agents. Hot melt powder comes in powder form.

DTF hot melt powder isn’t just used in the DTF transfer process—it’s got a bunch of other uses, too. DTF hot melt powder is used in printing various textiles, leather, paper, wood, and other materials, as well as in the preparation of various glues. The glue made with it has these great properties: it’s water-resistant, has high fastness, dries fast, doesn’t block the network, and doesn’t affect the color of the ink. It’s a new, eco-friendly material.

Here’s how DTF hot melt powder is used in the DTF heat transfer process:

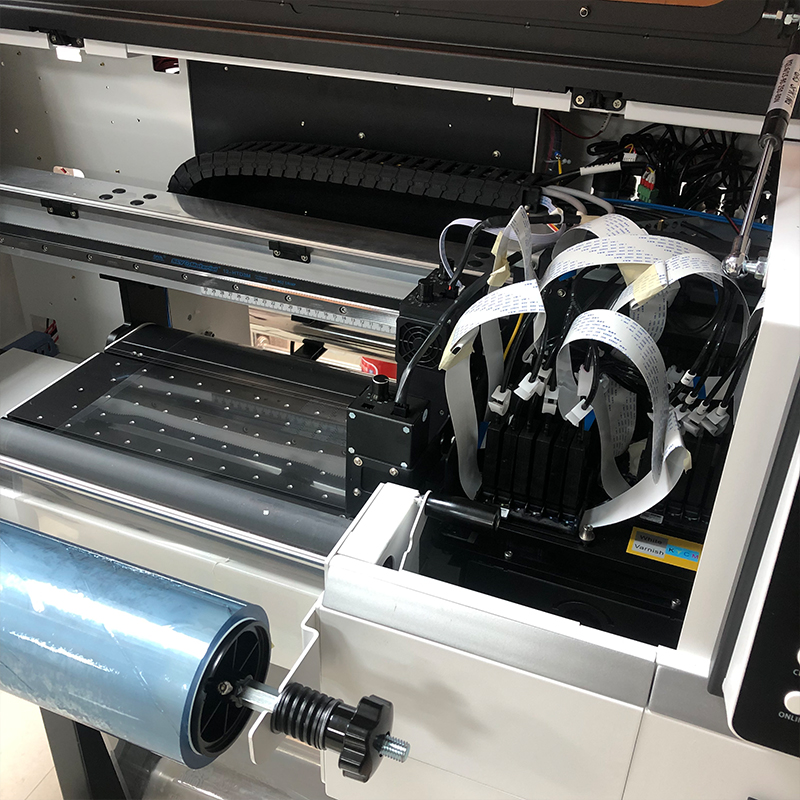

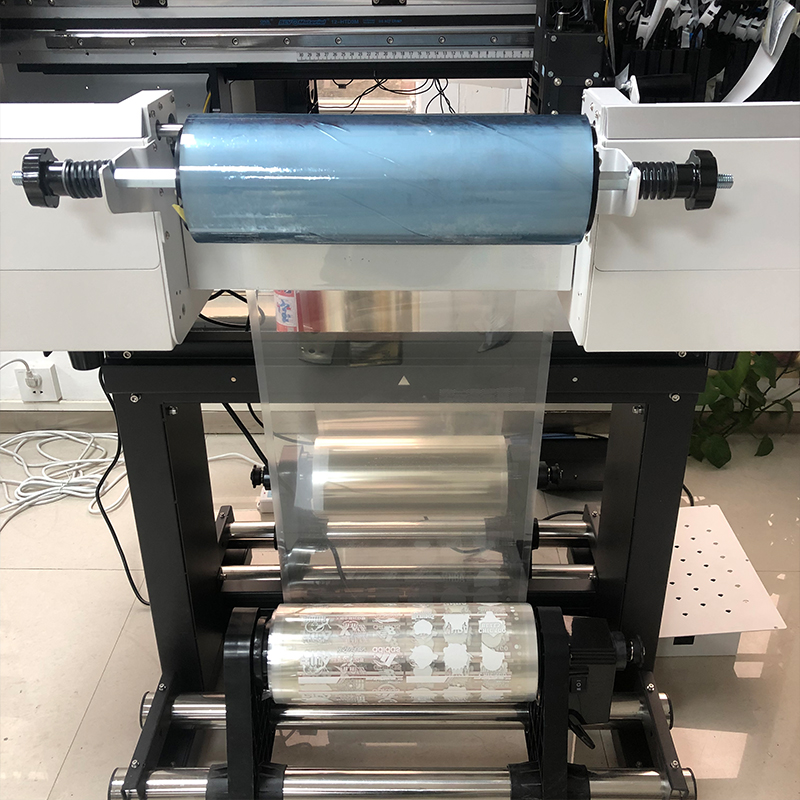

Once the DTF printer has printed the color part of the pattern, a layer of white ink is added. Then, the DTF hot-melt powder is evenly sprinkled on the layer of white ink through the dusting and powder shaking functions of the powder shaker. Since the white ink is liquid and moist, it’ll stick to the DTF hot-melt powder automatically, and the powder won’t stick to areas where there’s no ink. Then, you just need to enter the arch bridge or crawler conveyor to dry the pattern ink and fix the DTF hot melt powder on the white ink. This is how you get a finished DTF transfer pattern.

Then, the pattern is pressed and fixed on other fabrics like clothes through a pressing machine. Flat out the clothes, place the finished heat transfer product according to the position, use the right temperature, pressure and time to melt the DTF hot melt powder and stick the pattern and the clothes together to fix the pattern on the clothes. This is how you get custom clothes made through the DTF transfer process.

Hey there! We know that choosing DTF hot melt powder can be tricky. So, we’ve put together a few tips to help you make the right choice.

1. Thickness of powder

Coarse powder is thicker and harder. It’s good for coarse cotton, linen, or denim. Medium powder is thinner and softer. It’s good for general cotton, polyester, and medium- and low-elastic fabrics. Fine powder is good for T-shirts, sweatshirts, and sportswear. It can also be used for small wash water labels and marks.

2. Mesh number

DTF hot melt powders are divided into 60, 80, 90, and 120 mesh. The larger the mesh number, the better it can be used on finer fabrics.

3. Temperature

DTF hot melt powder is also divided into high temperature powder and low temperature powder. DTF hot-melt powder requires high-temperature pressing to melt and fix on clothing. DTF hot-melt low-temperature powder can be pressed at low temperature, which is more convenient. DTF hot-melt high-temperature powder is resistant to high-temperature washing. Ordinary DTF hot-melt powder will not fall off when washed with daily water temperature.

4. Color

White is the most common DTF hot melt powder, and black is commonly used on black fabrics.