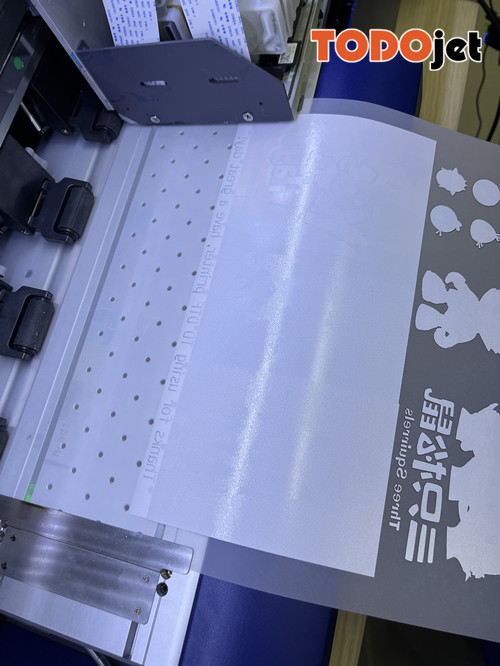

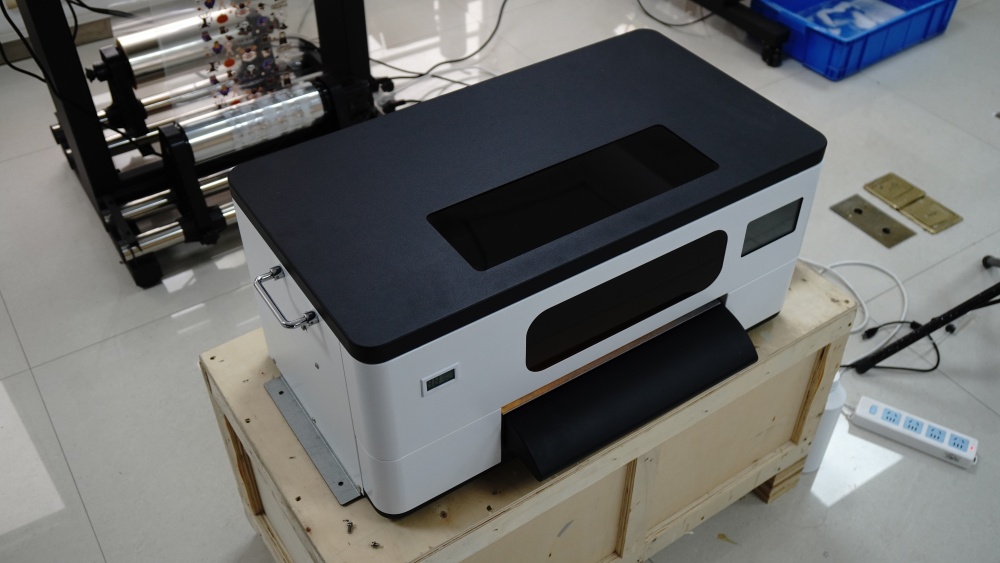

Digital High Speed DTF Printer A3 30cm Heat Transfer Direct To Film for all fabric t-shirts

Garment heat transfer can be subdivided into colloidal heat transfer and inkjet heat transfer. Glue heat transfer is suitable for batch operation and needs to be printed with a large four-color printing machine, and then coated with adhesive after printing. The cost of plate making and start-up is relatively high, usually at least 500 copies can be used in this process, otherwise the cost is too high.

Garment heat transfer can be subdivided into colloidal heat transfer and inkjet heat transfer. Glue heat transfer is suitable for batch operation and needs to be printed with a large four-color printing machine, and then coated with adhesive after printing. The cost of plate making and start-up is relatively high, usually at least 500 copies can be used in this process, otherwise the cost is too high. The cost of proofing is usually several hundred dollars. Inkjet heat transfer means that it needs an inkjet printer to print on special transfer paper, and it can be printed in a single piece, so the cost of proofing is very cheap, only tens of yuan, suitable for small family workshops, but not suitable for dark colors Printing of clothes. Advantages of colloidal garment heat transfer: It can print high-precision character photos and 3D game animation patterns with colorful, full-level, and delicate tones, which can be very close to computer design drafts. Shortcomings: The hand feel is not perfect. When you touch it with your hand, there is a gelatinous feeling, just like a piece of plastic film that sticks to the skin. Because it is not breathable. If only small patterns are used to decorate clothing products, it would be better. Of course, when making luggage products, there is no need to worry about whether it is breathable. Heat transfer T-shirt maintenance method: wash with warm or cold water below 40°C.

Adjust the thermostat and timer of the heat press machine to the desired temperature and time.

1.Lay the substrate flat on the silicone plate, then place the offset heat transfer drawing on the substrate, and press the handle down firmly until it is completely closed.

2.When the time indicated for hot stamping is up, the buzzer will sound, and the handle will be lifted back to its original position.

3.If it is cold torn, the heat transfer paper should be torn off after cooling; if it is hot torn, the heat transfer paper should be torn off immediately after the hot stamping is completed.

I believe that most people have a new understanding of clothing heat transfer, and different materials have different heat transfer methods.Hope the above introduction can help you.

Clothing heat transfer classification: 1. Foaming heat transfer: foaming heat transfer paper. Scope of use: children’s clothing, women’s clothing, advertising shirts, etc. 2. Flocking heat transfer: strong flocking three-dimensional feeling, soft to the touch. The newly developed multi-color flocking heat transfer and glitter flocking heat transfer are in the leading position in the industry. Scope of application: used in women’s clothing, sportswear, children’s clothing, plush toys, sweaters, etc. 3. Washing water mark: the pattern is clear in color and the lines are smooth and smooth. Super stretchy, washable and comfortable to wear. The color fastness level has reached the European level 4 or above, which is in line with the newer SGS environmental protection testing standards. Application: T-shirts, shirts, underwear, socks. 4. Swimsuit heat transfer: high elasticity, especially resistant to stretching. The environmental protection index meets the requirements of international adult fabrics. Scope of application: swimwear, body-building underwear, body-shaping underwear, fitness clothing, etc.