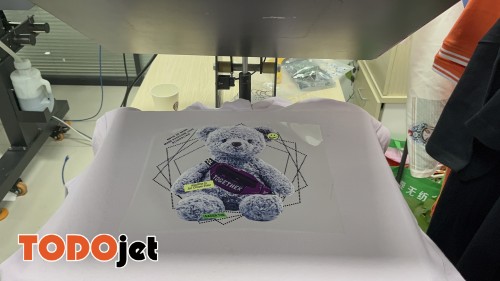

DIY T-shirts with A3 DTF Printer

You could try our A3 DTF Printer. Maintenance method of T-shirt and cotton textile after transfer printing?

1. Just transferred T blood will have a little hard, the feeling, you will become soft after washing.

2 The newly processed T-shirt must be cleaned up after 2 hours. Turn the clothes over to the reverse side and wash them.

3 Do not rub the surface of the T-shirt (the surface material does not attach dirt).

4 Do not wash with a detergent containing bleach.

5. Wash with warm or cold water below 40 C.

6 Try not to use a washing machine.

7 After washing, do not use the clothes dryer to shake dry.

8 Dry naturally and do not twist your clothes. Don’t expose your T-shirt in the sun.

9. If the clothes need to be scalded flat; dry can use medium temperature steam ironing (including elastic fiber can not be irat high temperature, so as not to damage the tissue structure of elastic fiber. influence

Clothing elasticity effect), do not iron directly on the pattern.

10 After Ironing. Do not plug clothings into narrow space, can use coat hanger county hang or flat spread, in order to maintain clothings flat appearance.

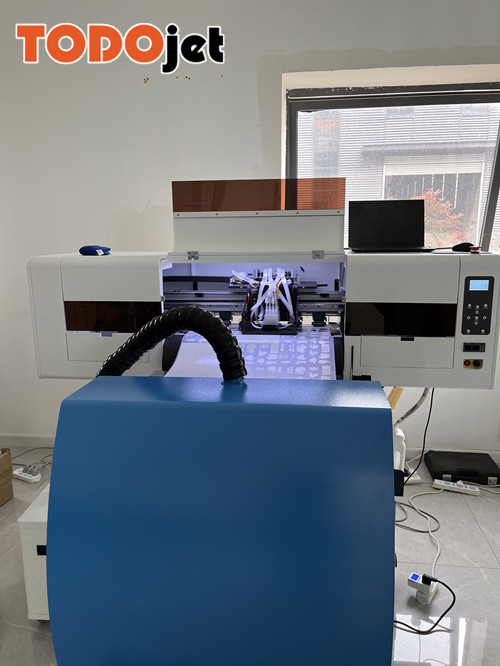

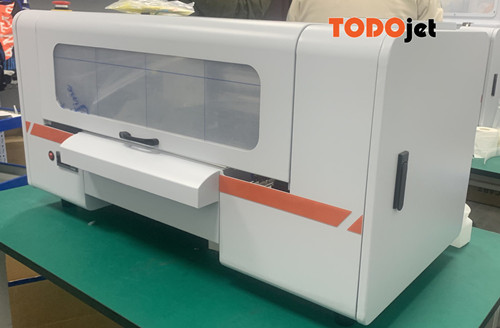

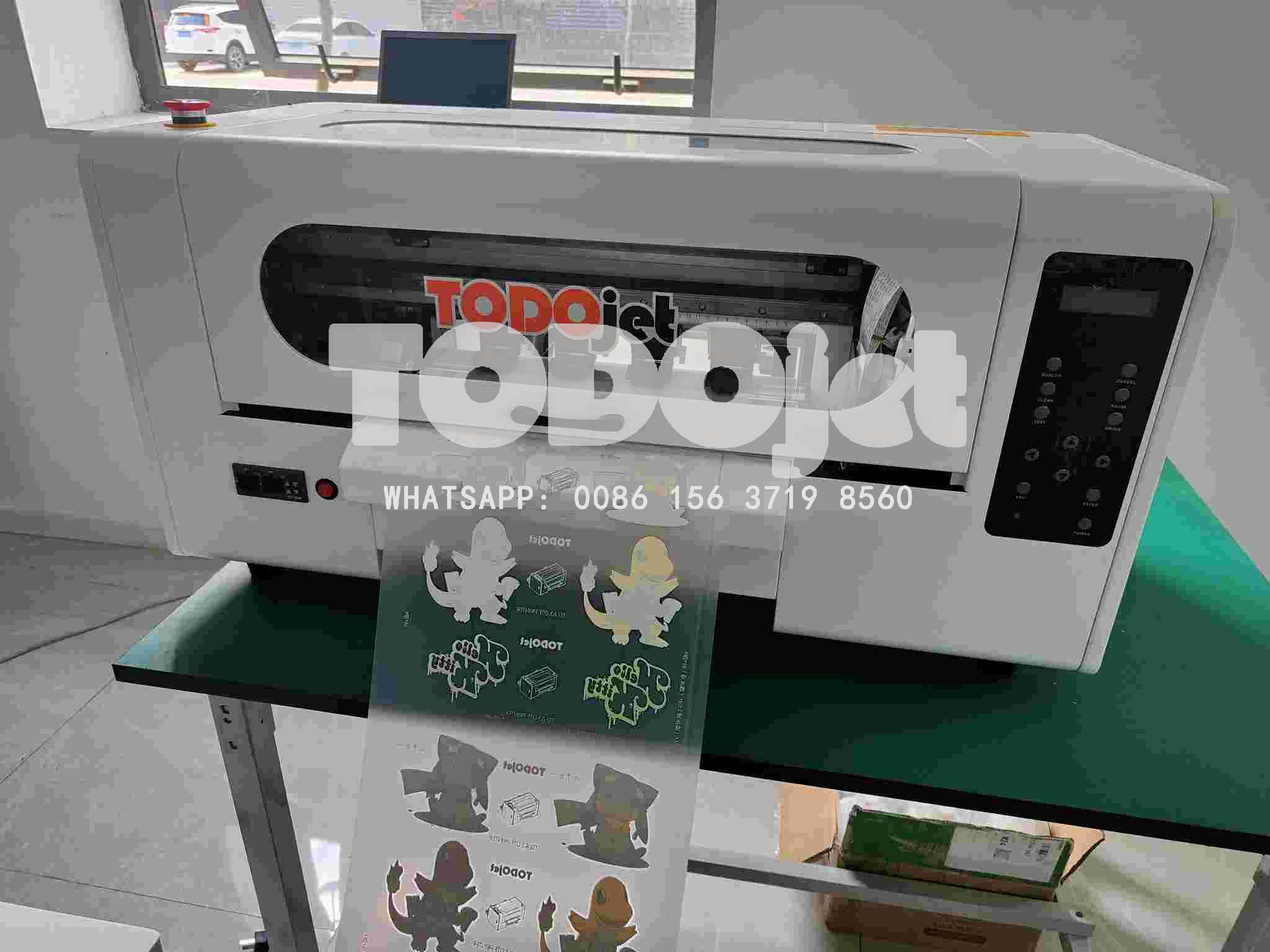

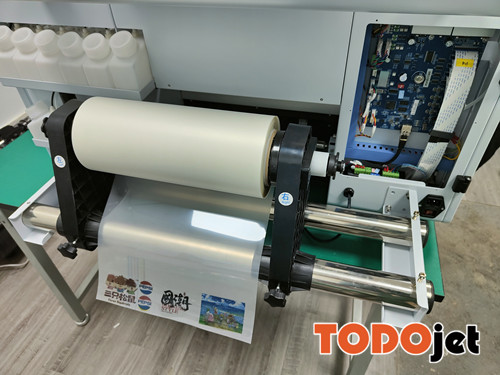

A3 DTF Printer:

Products display:

Maintenance method of T-shirt and cotton textile after transfer printing?

1.Just transferred T blood will have a little hard, the feeling, you will become soft after washing.

2 The newly processed T-shirt must be cleaned up after 2 hours. Turn the clothes over to the reverse side and wash them.

3 Do not rub the surface of the T-shirt (the surface material does not attach dirt).

4 Do not wash with a detergent containing bleach.

5.Wash with warm or cold water below 40 C.

6 Try not to use a washing machine.

7 After washing, do not use the clothes dryer to shake dry.

8 Dry naturally and do not twist your clothes. Don’t expose your T-shirt in the sun.

9.If the clothes need to be scalded flat; dry can use medium temperature steam ironing (including elastic fiber can not be irat high temperature, so as not to damage the tissue structure of elastic fiber. influence Clothing elasticity effect), do not iron directly on the pattern.

10 After Ironing. Do not plug clothings into narrow space, can use coat hanger county hang or flat spread, in order to maintain clothings flat appearance.