Do you know screen printing?

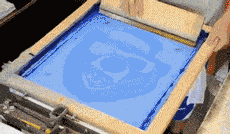

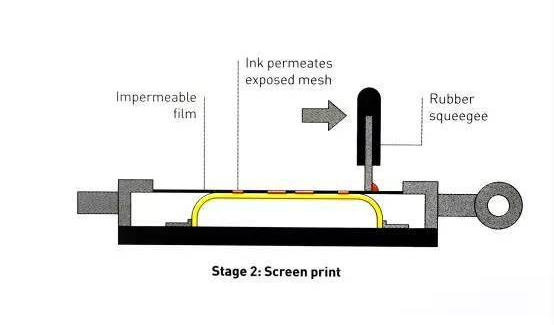

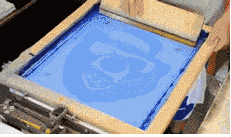

Screen printing, also called silk screen printing or silk screen printing, is a printing method in which a printing plate is supported on a finely woven silk screen, and the screen is taut and fixed on the screen frame.The material to be printed is placed under the screen frame, and the liquid ink is squeezed downward by a “squeegee”, passing down through the porous material.

Then, the image and text part of the ink-permeable printing plate is transferred to the material to be printed.

Screen printing differs from other printing forms in that it uses pigment inks, which form a thick layer of ink on the paper surface, resulting in bright and vivid colors.

1.Screen printing, also called silk screen printing or silk screen printing, is a printing method in which a printing plate is supported on a finely woven silk screen, and the screen is taut and fixed on the screen frame.

The material to be printed is placed under the screen frame, and the liquid ink is squeezed downward by a “squeegee”, passing down through the porous material.

Then, the image and text part of the ink-permeable printing plate is transferred to the material to be printed.

Screen printing differs from other printing forms in that it uses pigment inks, which form a thick layer of ink on the paper surface, resulting in bright and vivid colors.

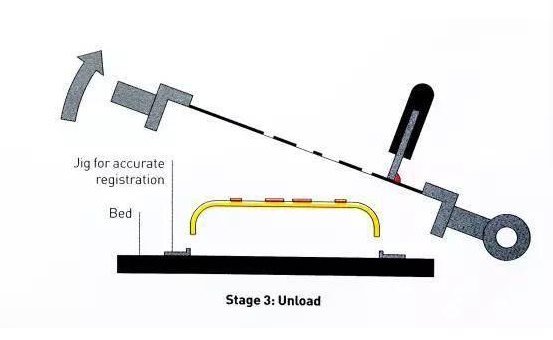

2. The process of screen printing:

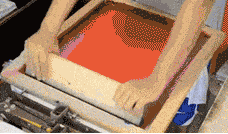

Step 1: Positioning the feed & ink deployment;

Step 2: Grscraper;

Step 3: confirm the test printing & batch.

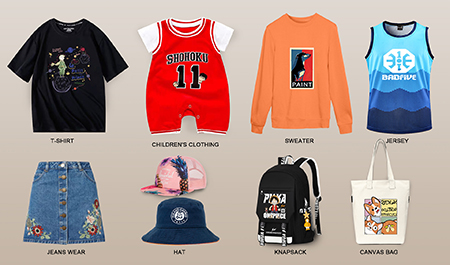

3. The effects:

4. Screen printing process cost

- The mold cost is low, but it still depends on the number of colors, because each color should be made separately

- Time cost: up to 30 per minute, 1-5 per minute

- Labor cost: In manual silk printing, the labor cost is too high, especially when it comes to colorful printing