A3 DTF with powder shaker Small size, big function

Powerful suction Simple design Automatic cleaning Factory direct sales

Product details

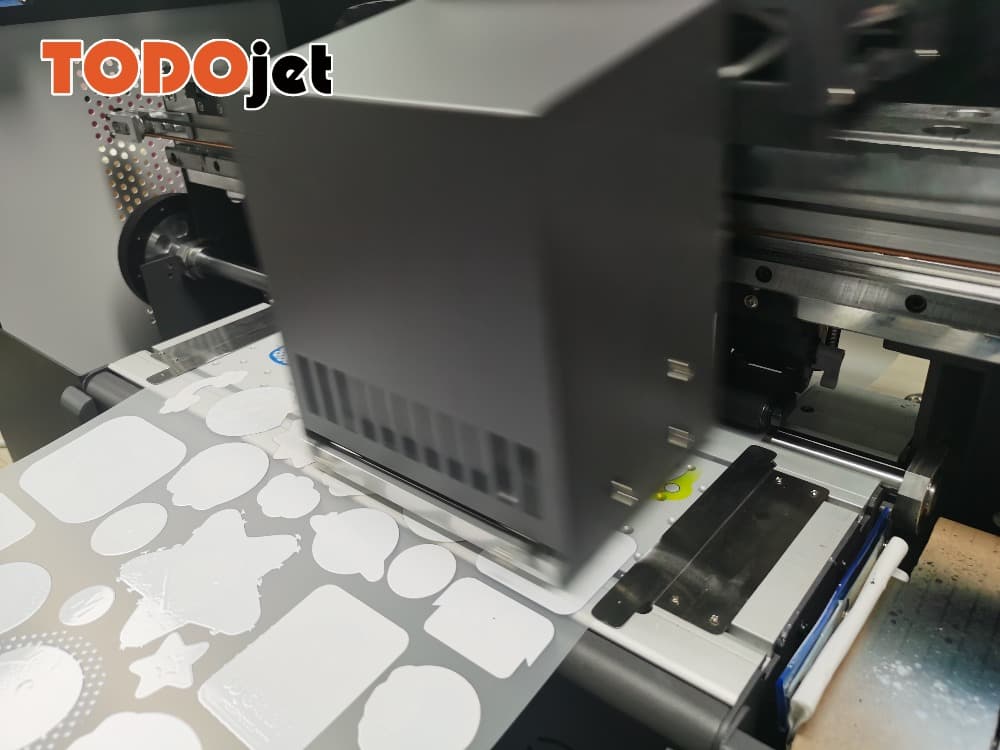

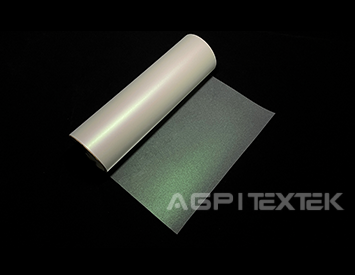

1. Fix the heat transfer film

★ There are slots on both sides of the film feeder to better fix the heat transfer film, making the printing position more stable and not easy to move

2. One-touch inking

★The printer’s manual inking function, one-touch inking, the inking process is simple and fast

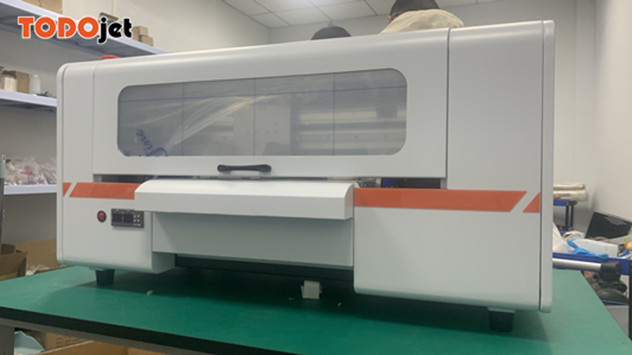

3. Printer cover

★The printer cover effectively reduces noise and provides a quieter working environment

4. Automatically clean the printhead

★White ink mixing system: When the printer is in standby mode, the printhead will be automatically cleaned every hour, so that the ink will flow smoothly and the life of the printhead will be effectively extended

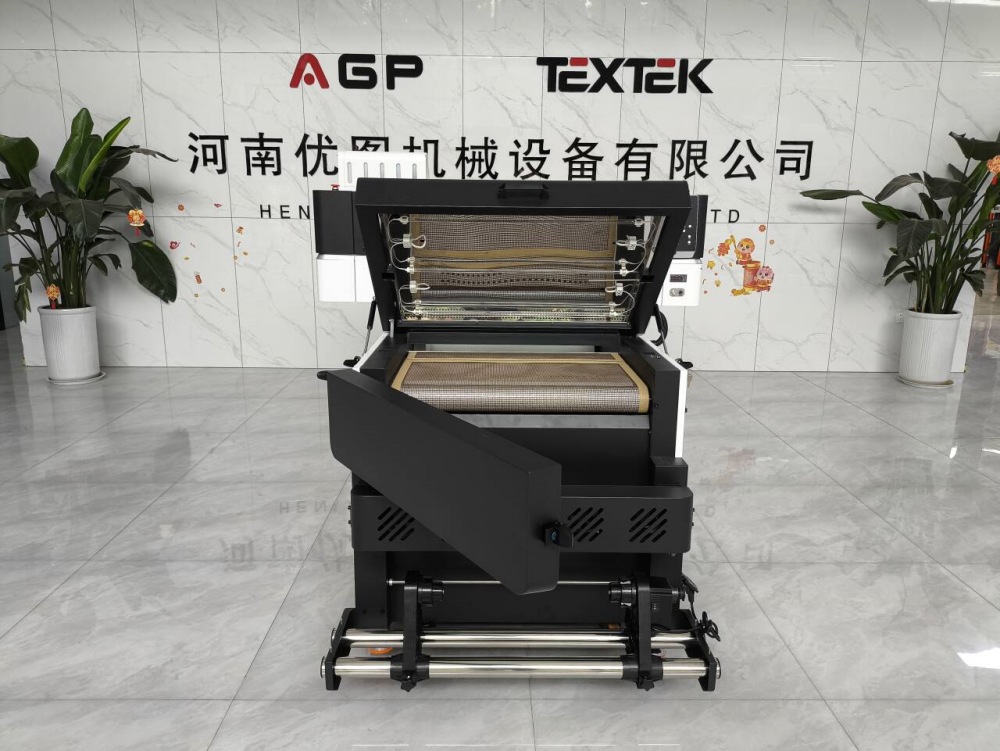

5. Dust cover for powder shaker

★Automatic operation of powder shaker: with dust cover to keep hot melt powder dry and hygienic, and with front heating system to make hot melt powder cover the pattern better

6. Powder shaking machine roller

★ A roller is added to the powder shaking machine, which is pressed on the heat transfer film to make the powder shaking machine spread the powder evenly, saving the cost of hot melt powder and reducing the waste of hot melt powder.

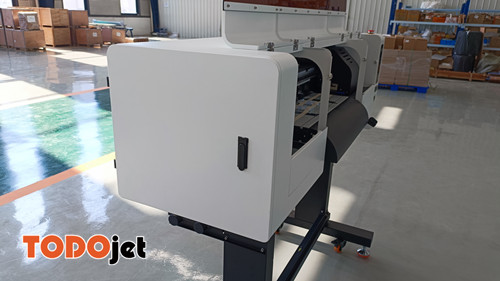

7. Automatic film rolling by powder shaking machine

★Automatic film rolling function of powder shaking machine: turn on the switch, the reel will automatically rotate, collect the printed pattern, and it is easier to store the printed heat transfer film

8. Powder shaking machine drying

★ Powder shaking machine drying system: It uses four lamps to increase the drying area, which is 38*52CM, to achieve the effect of quickly drying patterns and ink.