DTF transfer printer with powder shaking machine A3 Epson XP600 heads

This DTF printer Epson XP600 can be used to print PET films and transfer on cotton, polyester,nylon,canvas leather and other fabrics. A3 size DTF printer is very popular in garment industry.T-shirt Printing Machine works with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer.Customers who want to start new business prefer the DTF printer since it don’t need a heavy investment and can get back cost soon.

Parameters of DTF Printer

| Print head | 2pcs Epson XP600 heads |

| Print speed | 3-4.5sqm/h |

| Accuracy | 720*720dpi 4pass

720*1080dpi 6pass 720*1440dpi 8pass |

| Ink type | Pigment ink/Transfer film ink |

| Media Maximum Width | 32cm width |

| Media thickness | 1mm adjustable |

| Media type | PET film A3 size sheet / 30cm width roll |

| Heating system | Auto constant temperature drying system |

| Temperature | 160-170 cold/hot to tear |

| RIP software | Maintop |

| Power | AC110-220V, 50-60Hz, USB2.0, 350W |

| Operation environments | Temperature 20-30℃, Humidity 45%-65% |

| Machine size | 940*500*580mm |

| Packing size | 1000*640*64mm |

| Gross weight | 89kg |

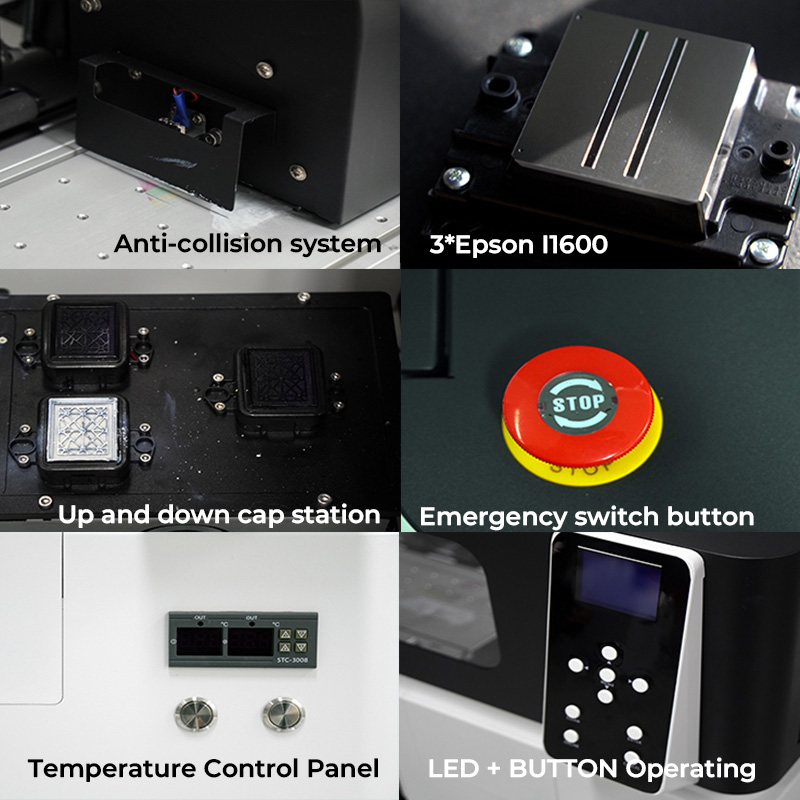

Feature of DTF transfer printer

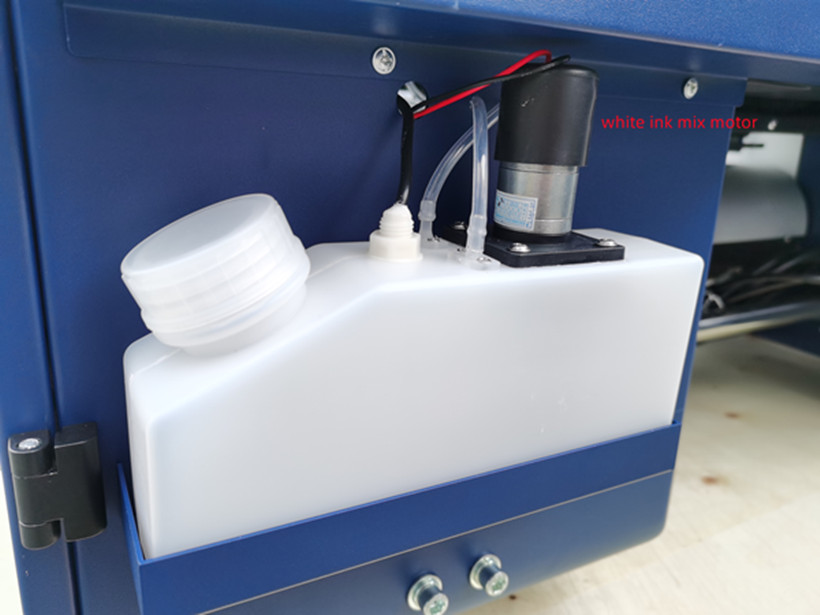

Advanced white ink circulation system:stir the white ink to prevent white ink from clogging.

CMYK+ Fluorescent Orange + Fluorescent Green + White:multi-color printing makes a richer and vivid performance.

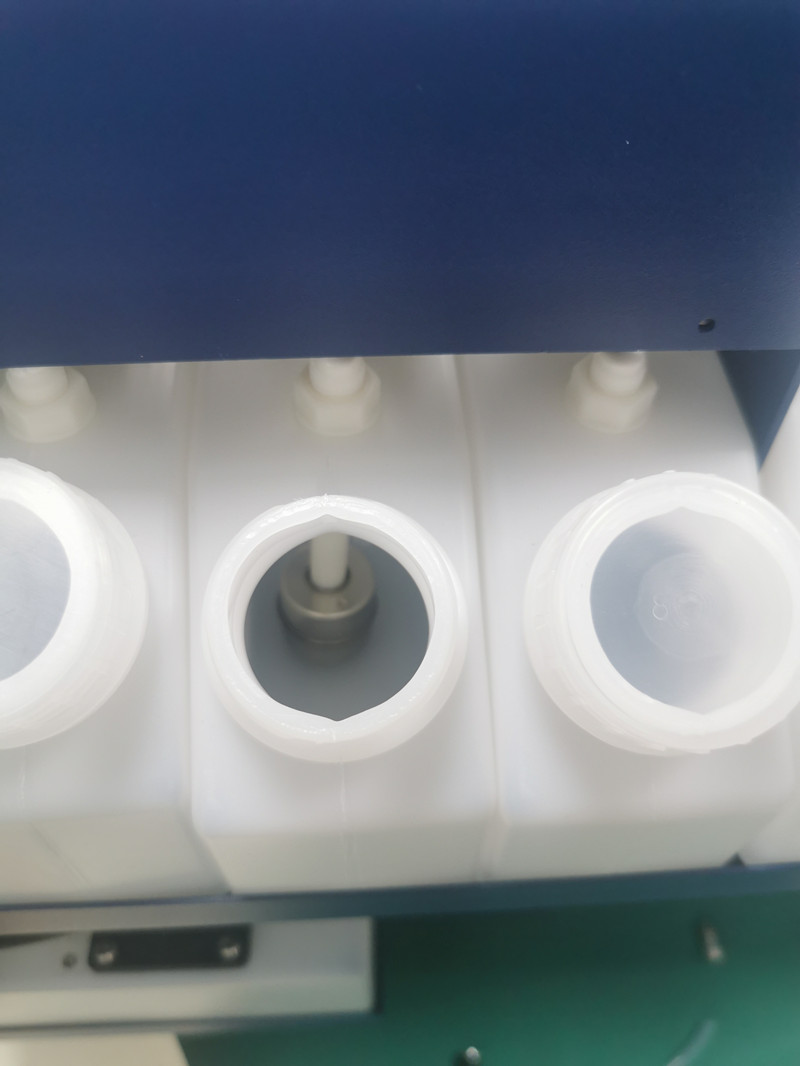

Ink low alarm

The machine is equipped with an ink shortage alarm. When the ink level is lower than a certain level, it will alarm to remind the user to add ink.

The grooves and holes under the scraper are convenient for the discharge of waste ink and ensure cleanliness and no pollution to the greatest extent. Ordinary sponges will have peculiar smell after a long time.

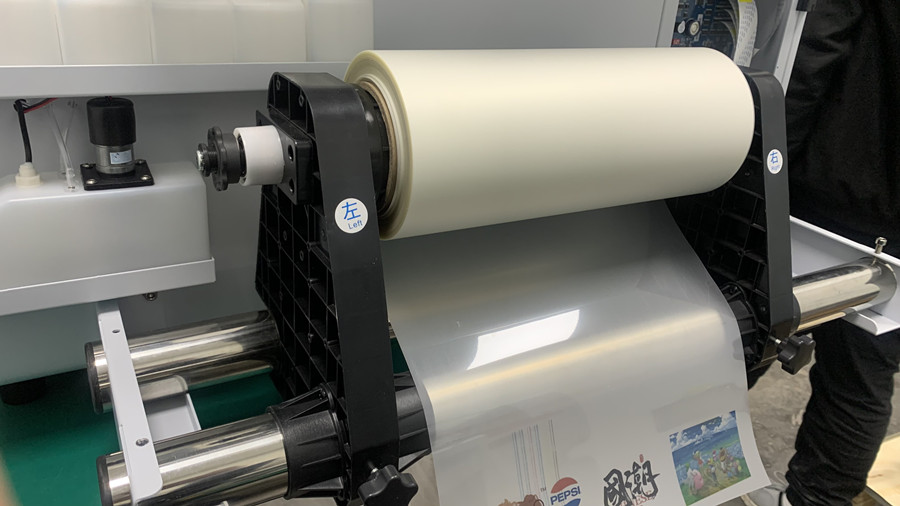

Auto feeding and take up system

Working Process

Design pattern.

Adjust the printer parameters in the RIP software and print the pattern on the PET film.

Sprinkle powder, shake powder, heat PET film, then dry automatically.

Use heat press machine to transfer on garments.