TEXTEX DTF65 Four heads DTF printer–direct to film printer with powder machine

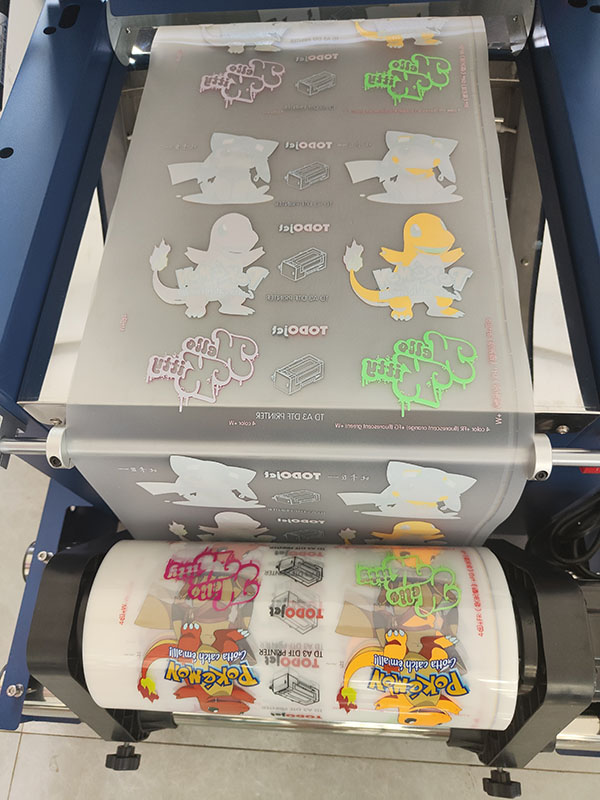

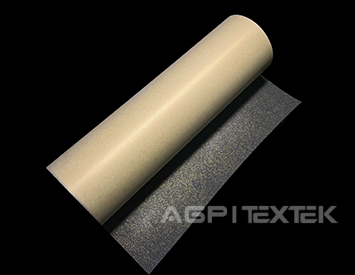

DTF printer usually used together with powder dryer machine,we printing on the PET film first with special pigment ink,and then a powdered glue is applied to the back and then heat cured ready for storage or instant use. Compare to DTG printer, DTF no limit about the non-cotton fabric,and no need pre-treatment, also this way can work out not the mass printing.

DTF printer usually used together with powder dryer machine,we printing on the PET film first with special pigment ink,and then a powdered glue is applied to the back and then heat cured ready for storage or instant use. Compare to DTG printer, DTF no limit about the non-cotton fabric,and no need pre-treatment, also this way can work out not the mass printing.

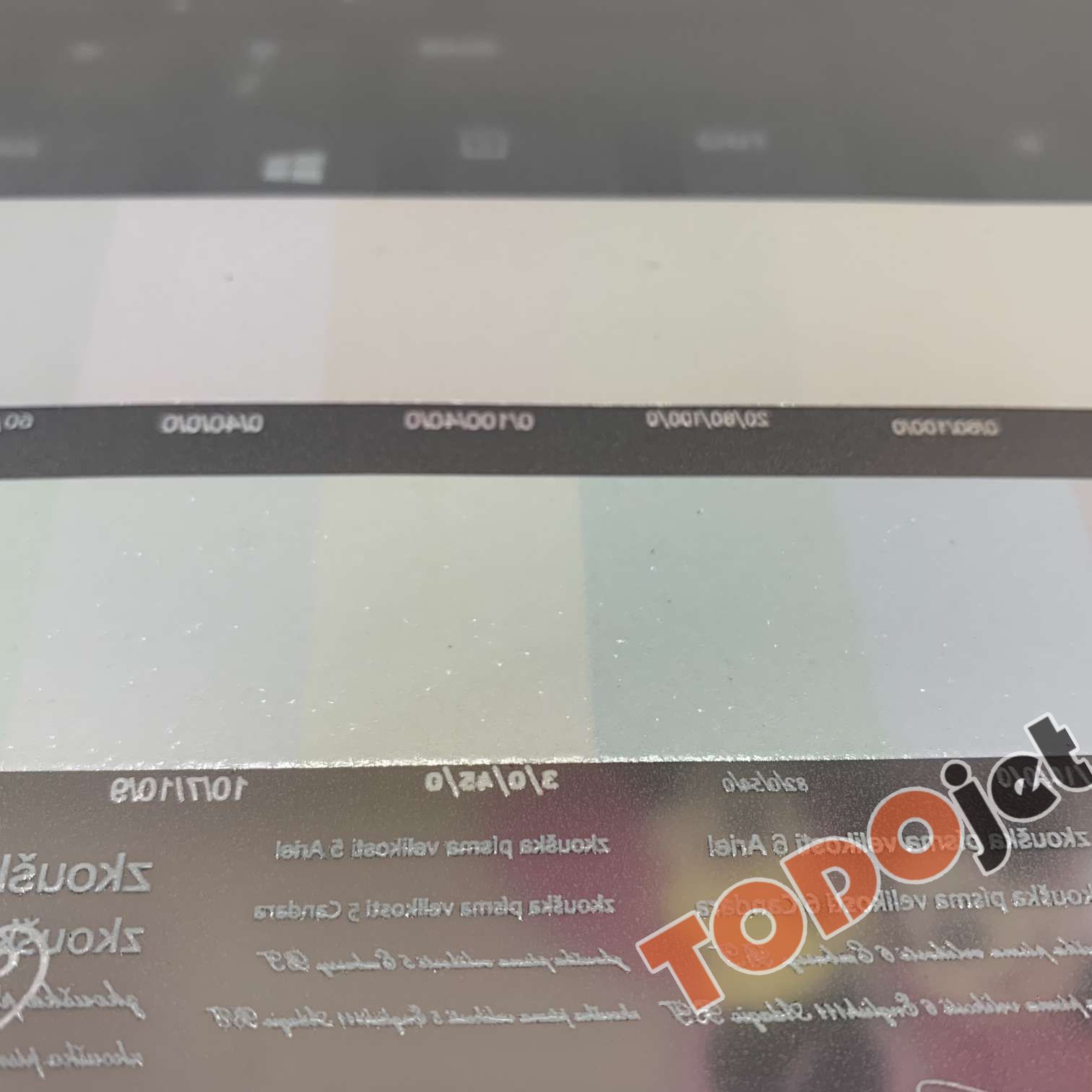

This printer can be configured with XP600 printhead, 4720 printhead or orginal i3200 printhead.Compare to two heads printer, 4 heads with fast speed and you can have more choices about fluorescent color.

No limit on fabric materials

No need pre-coating

CMYK+ White (Fluorescent color for option)

2pcs EPSON i3200-A1 (4 heads for option)

Printing width: 60cm

Printing Speed: 10~15sqm/h

Software: Maintop/Photoprint/RIIN/CAD Link

| Model | DTF-A602 | DTF-A603 | DTF-A604 |

| Printhead | 2*Epson l3200-A1 | 3*Epson 13200-A1 | 4*Epson l3200-A1 |

| Printing Color | 4C+W | 4C+Fr+Fm+Fy+Fg+W | 4C+W |

| Printing Speed | 6PASS 6-10m²/h 8PASS 4-7m²/h |

6PASS 6-10m²/h 8PASS 4-7m²/h |

6PASS 15m²/h 8PASS 13m²/h |

| Printing Size | 600mm | ||

| RIP Software | Riin/Flexiprint/Cadlink/Maintop,etc. | ||

| Media Transfer | Auto feeding and two-motor take-up system | ||

| Heating Method | Front and back independent heating | ||

| Ink System | Auto ink supply,white ink circulation and stirring | ||

| Power Supply | 110V/220V 50-60HZ 350W/4000W | ||

| Work Environment | Temperature:20-30°C Humidity:40-70% | ||

| Package Size/Weight | Printer:189*74*85cm 220kg | ||

| Powder Shaker: 92*73*117cm 127kg | |||