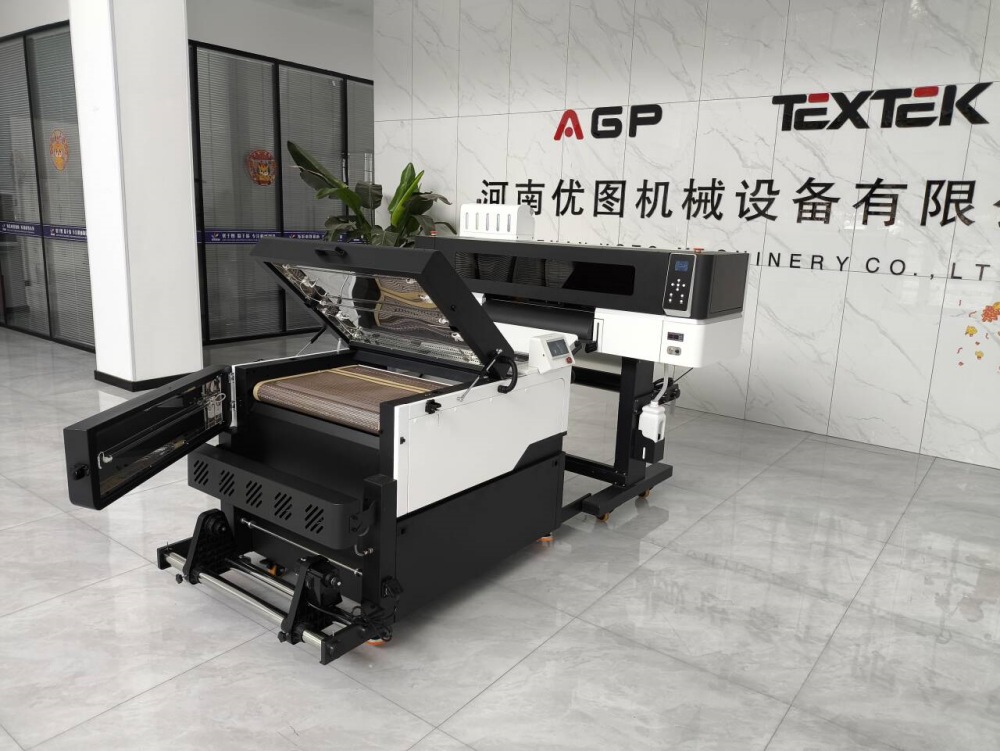

Fast shipping DTF printer any fabric printing a3 dtf printer printing machine 30cm shaker powder machine

1. Automatic powder shaker or oven

Generally speaking, when the cost-effective solution is adopted, the T-shirt printing white ink heat transfer printer, when the white ink direct-injection machine prints the pattern on the PET water-based film, we can cut each one out separately, manually apply the hot melt powder, and then go through After the high temperature of the oven, you can proceed to the next step of pressing; while the fully automatic solution is that the white ink direct-injection transfer machine prints the pattern while the automatic powder shaker automatically shakes the film and melts the powder at high temperature. Rewinding and standby, a series of actions are free of manual intervention. White Ink Heat Transfer Printer

What are the printing steps of the white ink heat transfer process?

1. Automatic powder shaker or oven

Generally speaking, when the cost-effective solution is adopted, the T-shirt printing white ink heat transfer printer, when the white ink direct-injection machine prints the pattern on the PET water-based film, we can cut each one out separately, manually apply the hot melt powder, and then go through After the high temperature of the oven, you can proceed to the next step of pressing; while the fully automatic solution is that the white ink direct-injection transfer machine prints the pattern while the automatic powder shaker automatically shakes the film and melts the powder at high temperature. Rewinding and standby, a series of actions are free of manual intervention. White Ink Heat Transfer Printer

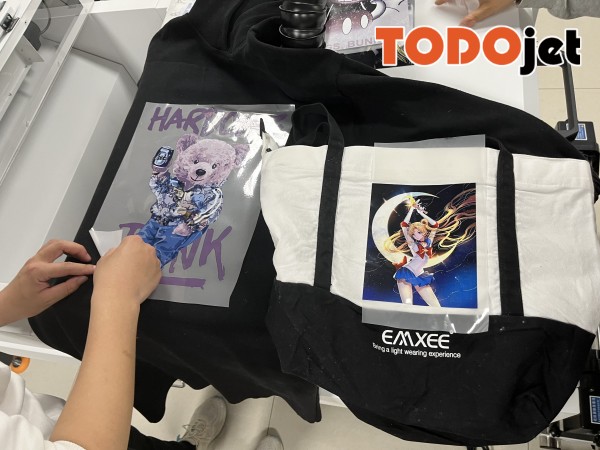

2. Pressing and fixing equipment

After printing out the high-temperature melted powder in the previous step, the Yunfu white ink heat transfer printer can directly place the printed PET film on clothing, T-shirts and other fabrics that need to be printed for high-temperature pressing. After the temperature cools down, slowly tear it off. Drop the film above, you’re done, no engraving white ink heat transfer printer, the whole process is as simple as that;

It can be said that the new white ink direct-injection heat transfer process saves labor under the strict environmental protection requirements. The washing fastness of the finished garment printing reached 3.5 and it is soft and washable. It can be said that this new printing process is still worthy of affirmation and investment. White Ink Heat Transfer Printer