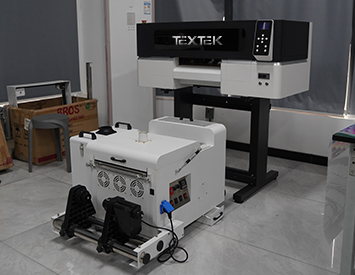

High Speed Small Format Digital Printing Machine Inkjet PET Film Heat Transfer DTF Printer

The digital direct injection process of pure cotton paint, which has been developed for many years, is the most variable in digital printing at present, but its color, fastness and hand feel have been improved to varying degrees. Among them, the most innovative improvement is the combination of The silk screen paste process and the white ink direct injection process, these two process schemes have greatly increased the market share of the coating direct injection process.

The digital direct injection process of pure cotton paint, which has been developed for many years, is the most variable in digital printing at present, but its color, fastness and hand feel have been improved to varying degrees. Among them, the most innovative improvement is the combination of The silk screen paste process and the white ink direct injection process, these two process schemes have greatly increased the market share of the coating direct injection process.

White ink direct injection. In fact, white ink appeared very early, and everyone has high hopes, but the overall progress of its direct injection process is not great. With the development of industry technology and the demand of the market, everyone is looking for a white ink direct injection solution that is more suitable for production. According to the speed of technological development, in the next six months at least, the white ink direct injection solution will become a tuyere in the industry. Whoever stands in the tuyere will fly higher. This is the best time to promote successful counterattacks by small companies and consolidate the status of large companies in the industry.

At present, pure cotton direct-injection corsage printing equipment is mainly based on elliptical machines and treadmill direct-injection machines, which can well meet most of the current printing needs.