Hot sale Mini DTF Oven A3 Size 30cm dtf pet film heating transfer t-shirt logo a4 a3 Sheets

Adjust the thermostat and timer of the heat press machine to the desired temperature and time.

1.Lay the substrate flat on the silicone plate, then place the offset heat transfer drawing on the substrate, and press the handle down firmly until it is completely closed.

2.When the time indicated for hot stamping is up, the buzzer will sound, and the handle will be lifted back to its original position.

3.If it is cold torn, the heat transfer paper should be torn off after cooling; if it is hot torn, the heat transfer paper should be torn off immediately after the hot stamping is completed.

The simple way to test the foaming heat transfer is that if the color of the flower is dark enough, the foaming should be continued.

1. No dark color: especially black, zhi leather, dark brown and other colors, because too much paint will make the foaming heat transfer unable to develop. Therefore, foaming heat transfer products are only suitable for light and medium colors. However, the above purpose can be achieved through the secondary process: that is, the foaming paste is printed first, and then the black, turquoise and dark brown pastes are printed after drying. Printing gold, printing silver, has the effect of icing on the cake and beautiful.

2. Special person operation: even force: it is advisable to cover the surface of the fabric with the foaming heat transfer paste evenly. If the force is too small, the printing will not pass through, and if the force is too large, there will be the disadvantage of blistering on the back.

3. Put it on the next version: the sticking of the plate during strict heat transfer and the sticking phenomenon when hanging and drying will cause all previous efforts to be lost. As a new technology, digital heat transfer has been upgraded on traditional heat transfer.

Clothing heat transfer classification:

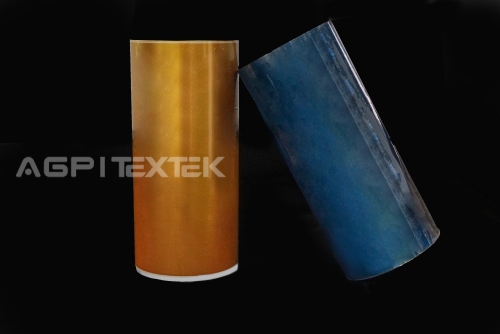

1. Sublimation heat transfer: After heat transfer, the pattern color completely penetrates into the textile fibers. The image is vivid, the air permeability is good, there is no hand feeling, and the color does not fade for a long time. Application: T-shirts, sweatshirts, etc.

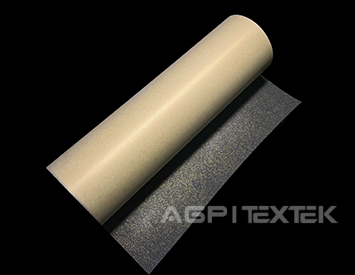

2. Crystal Symphony Heat Transfer: The surface is bright, crystal clear and soft to the touch. Has a strong sense of crystal illusion. Scope of use: advertising shirts, children’s clothing, fashion, etc. 3. Matte heat transfer: It belongs to the cold tear heat transfer process. The heat transfer company adopts a new heat transfer process developed by imported cold tear professional release materials. The edge of the pattern is smooth and has the matte effect of printing and laminating. Soft and natural colors, noble and elegant. Cold tearing technology, suitable for printing factory, garment factory mass hot stamping.

4. Bright surface heat transfer is a kind of color heat transfer process. It belongs to the cold tear heat transfer process. The edge of the pattern is smooth, and it has the bright effect of printing and laminating. The conjunctiva is thick and noble and gorgeous. Cold tearing technology is suitable for large-scale hot stamping in printing factories and garment factories. Digital heat transfer technology is a new technology.

How to make sure the heat transfer is firm? As we all know, heat transfer attaches great importance to its fastness. Most of the current test methods for color fastness of heat transfer are simulated tests or comprehensive tests according to the environment and conditions of the action. color to assess the fastness grade. How to ensure the firmness of heat transfer? Glue quality, clothing fabric, hot stamping process are the main factors. 1. Glue quality of heat transfer: Rubber grade: mainly synthetic rubber as the main raw material, suitable for the screen printing production process of heat transfer heat transfer, and superior to knitted fabric, TC, cotton and other fabrics Fastness. Polyurethane grade: With polyurethane as the main material, it is mainly used in thermal transfer elastic grades and screen printing production processes such as fine-line washing water label heat transfer, etc., and has superior bonding fastness to elastic fabrics, leather and other fabrics.