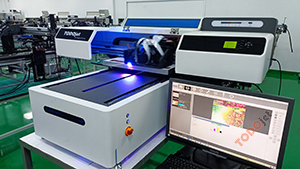

How to solve the UV flatbed printer nozzle surface Accumulated ink ?

When the UV flatbed printer nozzle is used for a long time, it is easy to ink on the surface area. If left alone, after a long time, the nozzle will easily become clogged. There are generally five causes of this phenomenon. Depending on the design of the UV flatbed printer from different manufacturers, there may be 7 or 4 phenomenon, but mastering these five can basically solve more than 90% of the ink accumulation problem.

1. Drip caused by negative pressure being too low

When the negative pressure of the UV flatbed printer is too low, it will cause ink dripping from the print head. This is only necessary to adjust the negative pressure back to the normal range, and the software can also be manual. It should be noted that the negative pressure value of different manufacturers is different. Ask the original equipment manufacturer before adjusting.

2. The print head print too high cause fly ink

The spraying force of different types of nozzles is different. In the production mode, some nozzles have a printing height of 3mm, some have a printing height of 2mm, etc. At this time, the printing height of the UV flatbed printer needs to be reduced.

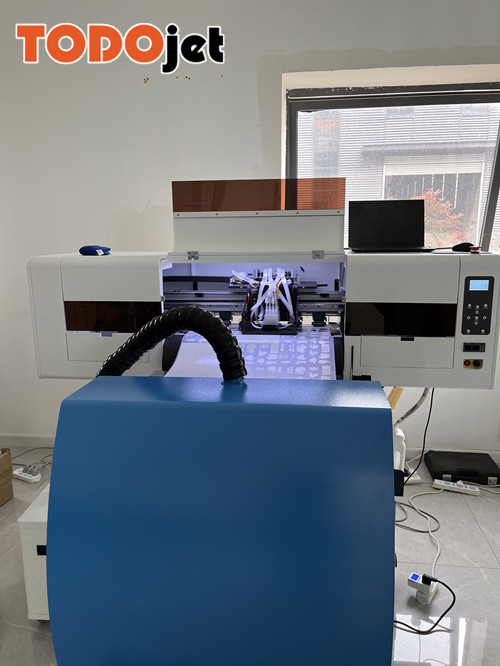

3. Foreign matter on the nozzle surface

Due to dust and other problems in the workshop, some foreign matter may fall on the surface of the UV flatbed printer nozzle. In this case, just wipe it clean.

4. Large ink output

When the amount of ink that the UV flatbed printer chooses to print is very large, a small amount of ink will accumulate on the surface of the print head. After the printing is finished, it can be cleaned.

5. Control software file is damaged

In such cases, if you have a backup, you can restore it again. No UV flatbed printer control software file backup, contact the original manufacturer and send an overlay.