How to solve the UV flatbed printer protection bottle flow ink ?

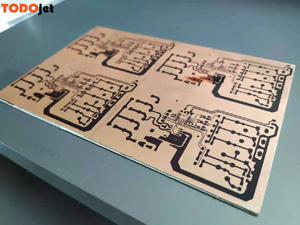

The ink in the protective bottle of the UV flatbed printer will directly lead to the inability to supply ink, and the print head will not be able to print the pattern normally. The occurrence of this kind of failure is usually caused by the negative pressure adjustment being too low, which causes back suction, the secondary ink tank sensor is abnormal, and the ink supply circuit is abnormal.

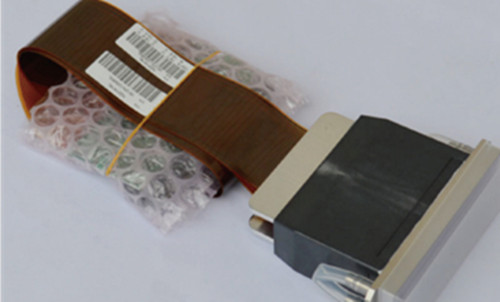

1.Negative pressure adjustment being too low

If the negative pressure value of the ink supply is too low, it will cause the uv ink to suck back. At this time, the ink will not be smoothly supplied to the nozzle. At this time, only the negative pressure value needs to be adjusted to return to normal. If it is manual, it needs to be adjusted manually. It should be noted that the normal value of the negative pressure of different models of UV flatbed printers is different, and there is no same range.

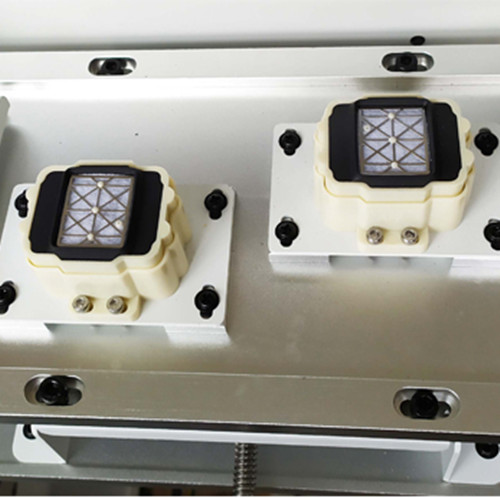

2.The secondary ink tank sensor is abnormal.

The secondary ink tank sensor of the UV flatbed printer is abnormal. You need to check whether the secondary tank sensor is sinking. If it is sinking, just bring it up. If it is repeatedly raised and sinks, it means that it is broken and you need to replace it with a new secondary ink tank.

3.Ink supply circuit is abnormal

Check whether the voltage of the ink supply circuit of the UV flatbed printer is high or low, or if the circuit is burnt out and short-circuited. If the above faults exist, after the device is shut down, repair the circuit