Main system and workflow of UV printer

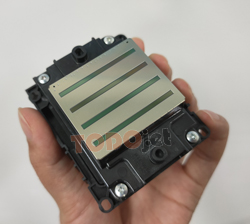

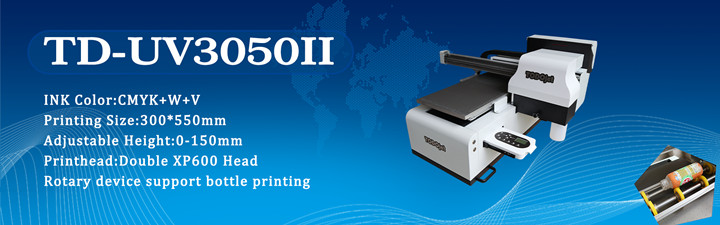

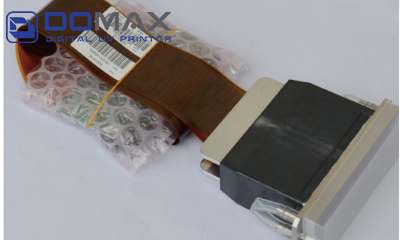

UV printing equipment such as UV flatbed printers, UV rolling and flattening machines, and UV cylinder printers all adopt mainstream drop-on-demand inkjet technology, of which piezoelectric inkjet methods account for more than 90% of the share. Common nozzles on the market include Epson nozzles, Seiko nozzles, Konica nozzles, Ricoh nozzles, Kyocera nozzles and so on.

Main system and workflow of uv flatbed printer

UV flatbed printers, UV roll-to-flat printers, UV cylinder printers and other UV printing equipment all use mainstream drop-on-demand inkjet technology, of which piezoelectric inkjet method accounts for more than 90% of the share. Common nozzles on the market include Epson nozzles, Seiko nozzles, Konica nozzles, Ricoh nozzles, Kyocera nozzles and so on.

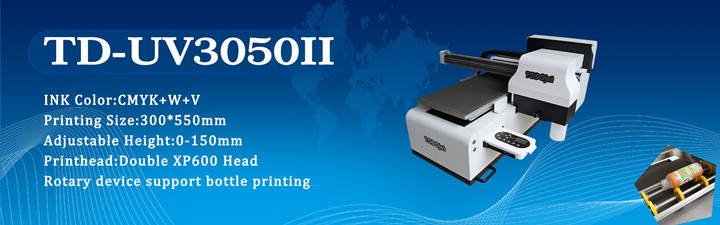

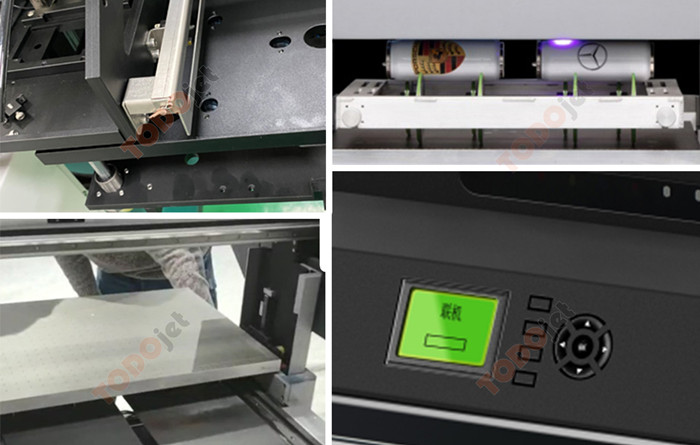

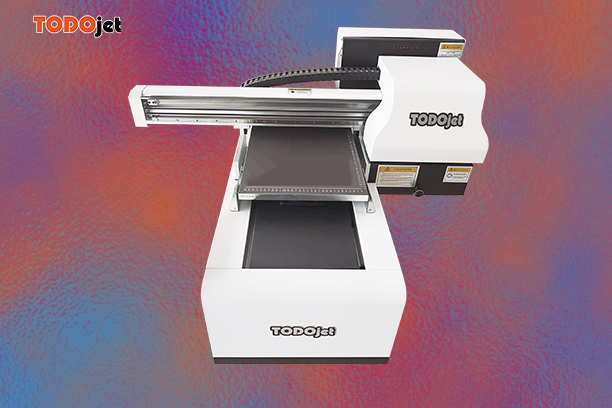

The UV flatbed printing system is mainly composed of an image processing system, a servo motor and a control system, an ink circuit negative pressure control system, a UV curing equipment, a suction vacuum platform, and a cooling system. The main functions of each system are as follows:

1. Image processing system: responsible for pattern editing, drawing, rip, etc. Common software includes photoshop, Monterey, etc.;

2. Servo motor and control system: control the movement of the trolley in the x, y, and z directions;

3. Ink circuit negative pressure control system: responsible for the ink supply of uv ink and ensure normal ink transmission. The negative pressure system currently widely adopts automatic negative pressure adjustment, which avoids the unstable ink supply problem caused by manual price adjustment negative pressure.

4. UV curing equipment: responsible for the curing and drying of UV ink on the surface of the material. The mainstream is UV curing with LED lamps, and a small amount of mercury lamps are used for high temperature baking.

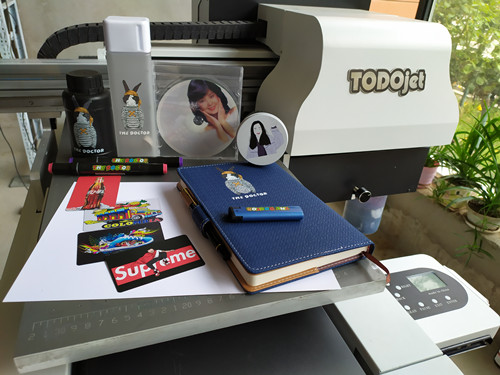

5. Suction vacuum platform: on the one hand, the placement of the substrate, on the other hand, the suction function can fix the soft material well, so as to prevent it from being lifted and scratching the nozzle.

6. Cooling system: It is used to dissipate heat for the core components of the equipment to avoid rapid aging, performance degradation, and unstable operation due to excessive temperature. The common ones are water cooling cycle and air cooling cycle.

In the actual substrate printing process of the uv flatbed printer, the printing quality of the material is realized by the combination of the printing environment, printing speed, feathering or not, the image processing system and the nozzle motion system, which depends on the manufacturer’s training. On the other hand, it comes from the continuous accumulation of experience.