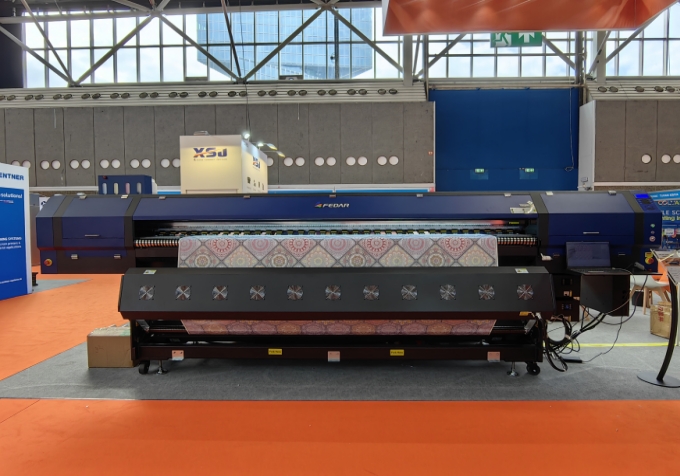

Maintaining Your Digital Printing Machine: Key Tips for Long-Term Performance

Maintaining a digital printer is critical to ensuring its long-term performance and stability. Regular cleaning, inspection, and maintenance are essential to prevent potential problems and ensure optimal print quality. Here are some important maintenance tips to follow:

Maintaining a digital printer is critical to ensuring its long-term performance and stability. Regular cleaning, inspection, and maintenance are essential to prevent potential problems and ensure optimal print quality. Here are some important maintenance tips to follow:

Digital printer environmental requirements:

1. Keep the print room free of dust and avoid placing the machine in environments prone to smoke and dust.

2. Maintain a constant temperature (18℃-30℃) and humidity (35%-65%) to prevent fluctuations that can affect print quality.

3. Avoid placing liquids or objects on the surface of the machine.

4. Make sure the machine is placed on a flat surface to prevent image shifting during printing.

5. Keep the machine away from household appliances, large magnetic fields, and electric fields.

Digital Printing Machine Maintenance Methods:

Grid: Observe if there are dust spots on the screen. If it needs to be cleaned, it is recommended to wipe it with a white cloth dipped in alcohol. The cleanliness and position changes of the grid will affect the movement of the ink carriage and the printing effect.

Filter: Check regularly for clogging and clean or replace as needed.

Ink Stack Cap: Keep it clean at all times because the ink stack cap is an accessory that directly contacts the nozzle.

Squeegee: Keep the ink stack cleaning unit and the squeegee blade clean and undamaged to avoid compromising the squeegee action.

Ink Cartridges and Ink Barrels: Ink cartridges and waste ink barrels are cleaned regularly. After prolonged use, the ink remaining at the bottom of the ink cartridges and waste ink barrels may agglomerate, resulting in poor ink flow. Ink cartridges and waste ink bottles must be cleaned regularly.

Voltage Stabilizer: It is recommended that each machine be equipped with a voltage stabilizer (for printer use only, except for drying), which should not be less than 3000W.

Ink: Make sure the ink cartridge has enough ink to avoid emptying the nozzle, causing nozzle damage or blockage.

Print Platform: Keep the print platform free of foreign objects to avoid scratching and damaging the nozzle.

Nozzle: Periodically check for debris buildup on and around the nozzle mirror and clean it. You can move the carriage to the cleaning position and use a cotton swab dipped in cleaning fluid to clean the ink residue around the nozzle without affecting the cleaning effect.

Ink bag: If the machine is used for a long time, check that the ink bag is not loose.

Transmission Part: Apply grease to the gear part, and add grease regularly to the gear meshing points such as the air expansion shaft gear for retracting and releasing materials, the guide rail slider, and the ink stack lifting mechanism. (It is recommended to add an appropriate amount of grease to the long belt of the cross carriage motor, which can effectively reduce noise).

Circuit Inspection: Check the power cord and receptacle for signs of aging.

Dryer: Periodically check the dryer’s power supply for aging and the internal light tube for damage.

Air Pump: Check the air pump for normal air pressure.

By following these environmental requirements, you can create an optimal printing environment that promotes consistent print quality, extends the life of the printer, and increases overall productivity.

If you’re interested in learning more about sublimation printers, DTF printers, or UV printers, feel free to reach out to us at info@fedar.net or via WhatsApp at +86 19137185989. We’d be happy to provide you with more information and answer any questions you may have.