TODOjet-Our latest direct to film Printers,NEW DIY T-shirt Printing Machine

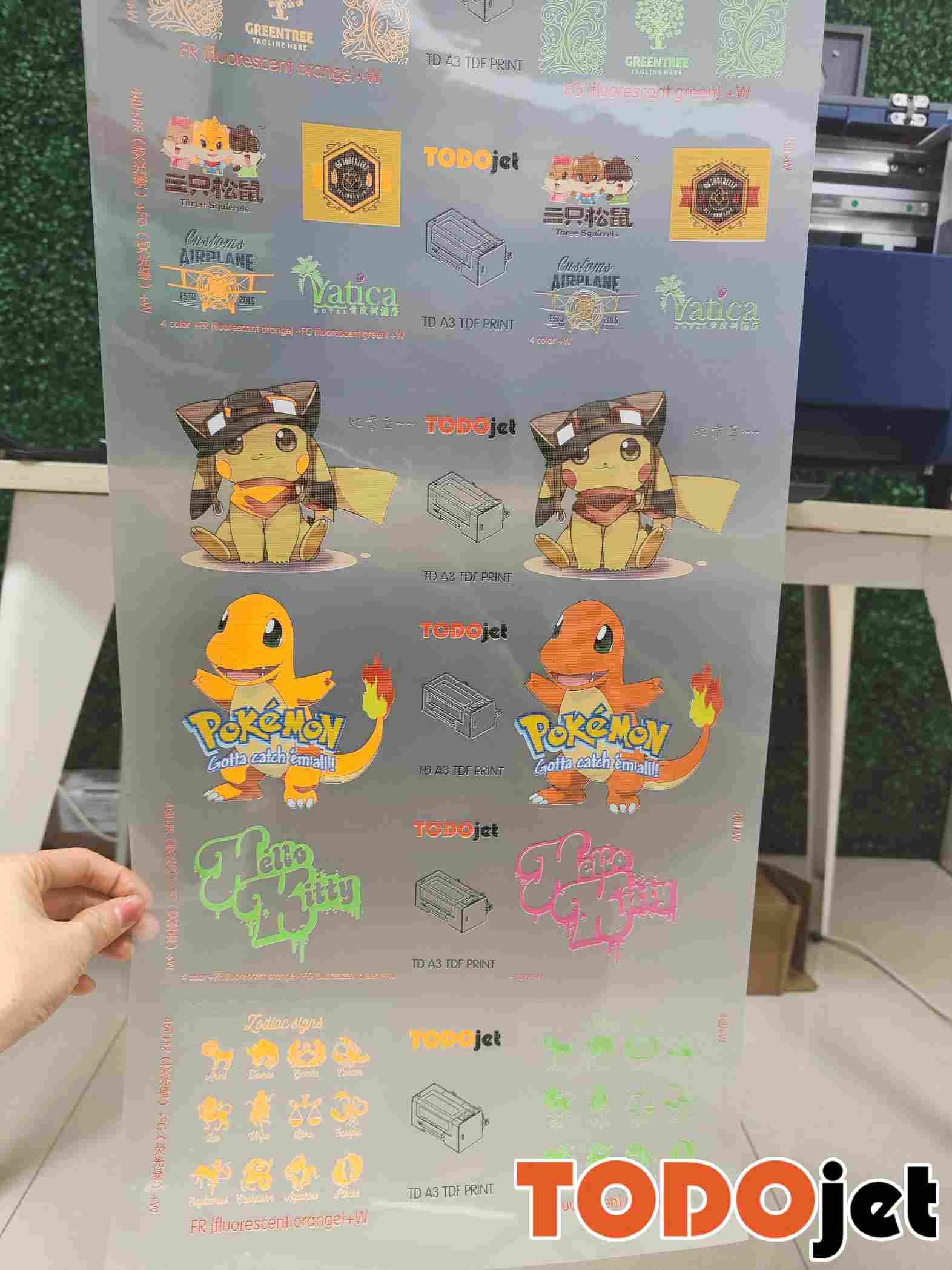

DTF printer is a new innovation technology in garment field. DTF means direct to film.The process of direct to film printer is to print on a film and directly transfer it onto fabric. Very simple and convenient than other traditional printing.DTF printer can be applied to cotton,polyester,linen,nylon,canvas and leather etc.The DTF printing process will work its magic on them.

Pros of Direct to Film Printing

Pros –

1.Works with almost all types of fabrics.

2.Does not require pre-treatment.

3.The process is faster and less tedious than DTG printing.

4.The fabric has a very slight hand touch.

5.4 color CMYK+ 2Fluorescent Color(orange and green) + white

6.No limit of fabric materials.

7.Affordable price to set up your business.

8.Mute guide rail without noise.

The basic step of direct to film Printers

1.Design pattern and use rip to typeset.

2.DTF printer print the image on the PET film.

3.Sprinkle DTF powder on the film by the powder shaker.

4.Transfer the image on the fabrics by the heat press machine.

Packaging photoes