Precautions for UV printing coating varnish process

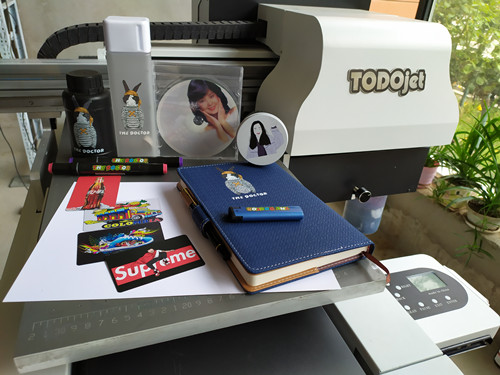

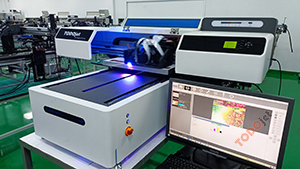

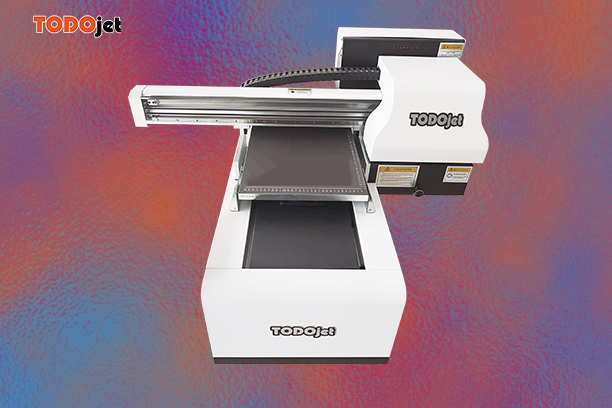

The surface of the uv printing material adopts the printing principle of piezoelectric inkjet. The uv ink is directly sprayed on the surface of the material and cured by ultraviolet light emitted by UV-led. However, in the daily printing production process, because some materials The surface is smooth, with glaze, or the application environment is more demanding, it is necessary to use coating or varnish treatment process to achieve high temperature resistance, waterproof, friction resistance and other characteristics.

So what are the precautions for the uv printing surface coating varnish process?

1. The coating is used to improve the adhesion of uv ink. Different uv inks use different coatings, and different printing materials use different coatings. If you don’t know how to choose a suitable coating, You can contact the manufacturer of the uv flatbed printer.

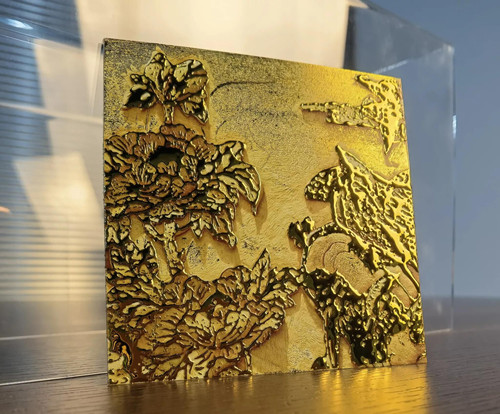

2. The varnish is sprayed on the surface of the pattern after printing the pattern. On the one hand, it presents a highlight effect, and on the other hand, it improves the weather resistance and doubles the storage time of the pattern.

3. The coating is divided into quick-drying coating and baking coating. The former only needs to be wiped directly to print the pattern, and the latter needs to be put in the oven for baking, then take it out and print the pattern. The process must be strictly followed, otherwise the effect of the coating will not be reflected.

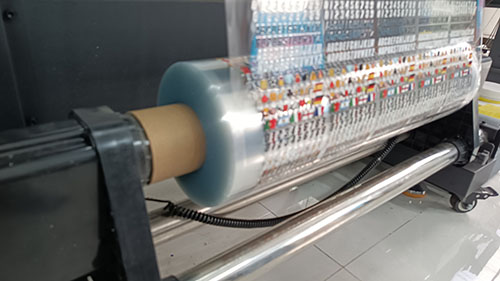

4. There are two ways to use varnish, one is to use electric spray gun, suitable for small batch products. The other is to use a curtain coater, which is suitable for mass products. Both of these are used after uv printing the surface.

5. When the varnish is sprayed on the surface of the UV ink to form a pattern, dissolution, blistering, peeling, etc. appear, indicating that the varnish cannot be compatible with the current UV ink.

6. The storage time of coating and varnish is usually 1 year. If you open the bottle, please use it diligently. Otherwise, after opening the bottle, it will deteriorate if it is not closed for a long time and it will not be usable.