Roll to roll A3 DTF XP600 i3200 dtf printer printing machine A3 PET Film 60cm 30cm and shaker oven

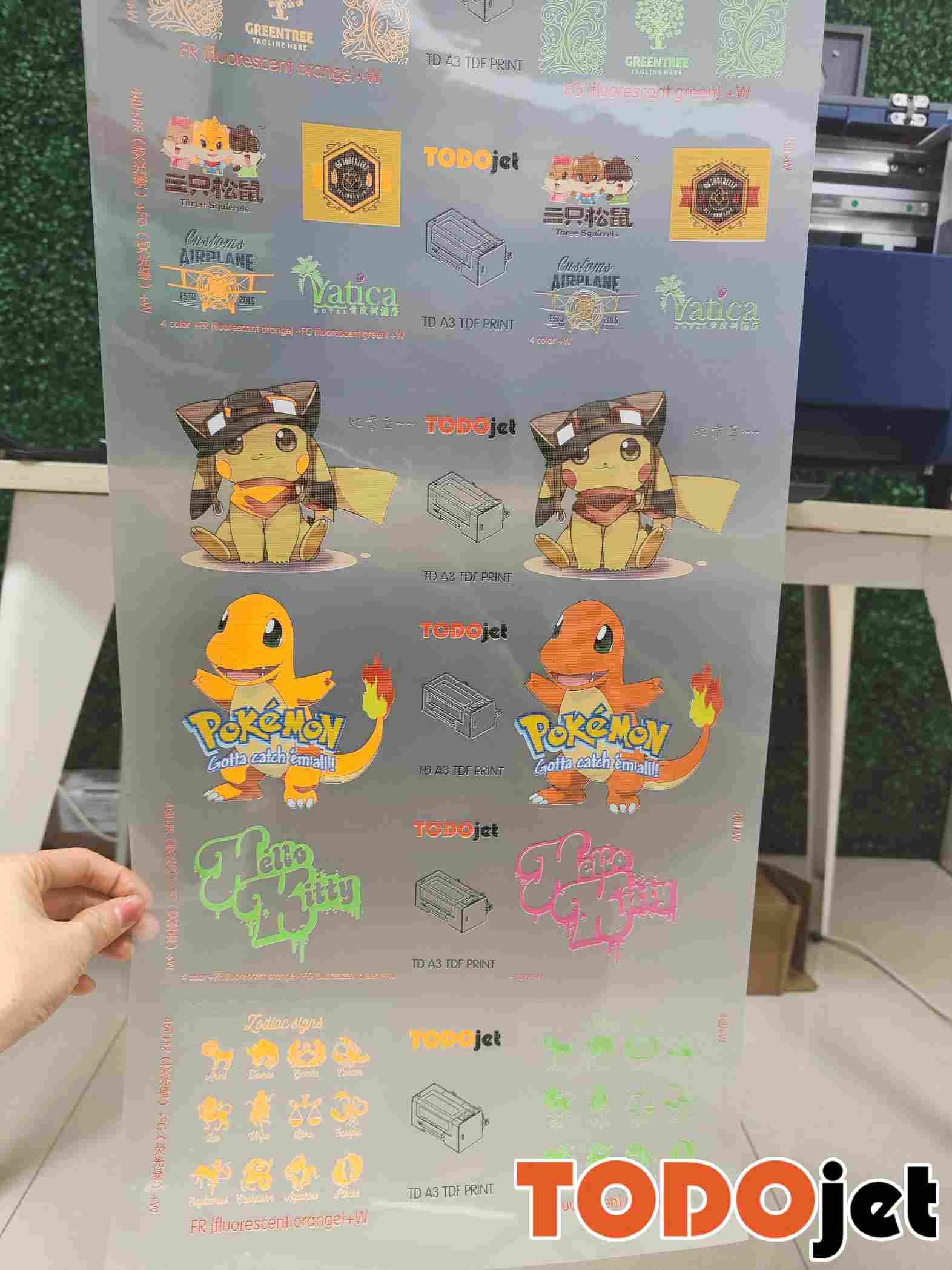

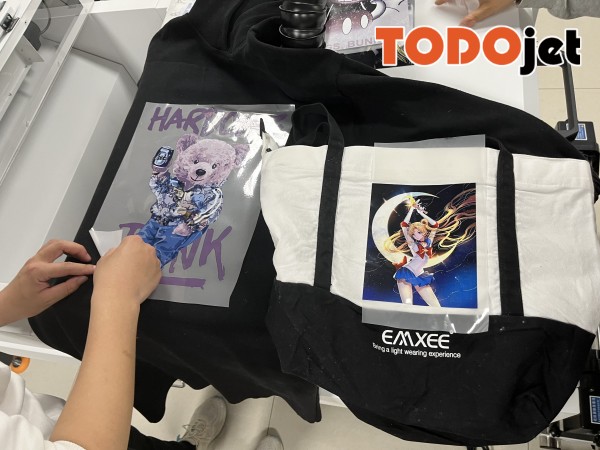

1. White ink and color ink come out with environmental protection paint heat transfer scheme, which is a subversive application technology of clothing heat transfer

2. It solves the problem of being picky about fabrics in the direct printing process, and the new heat transfer process is not limited to material transfer printing

3. No need to worry about color difference and color fastness, what you see is what you get

1. White ink and color ink come out with environmental protection paint heat transfer scheme, which is a subversive application technology of clothing heat transfer

2. It solves the problem of being picky about fabrics in the direct printing process, and the new heat transfer process is not limited to material transfer printing

3. No need to worry about color difference and color fastness, what you see is what you get

4. There is no need to engrave waste discharge and film covering, which effectively improves production efficiency. There are no restrictions on patterns, and the natural hollowing is lighter, thinner and more breathable

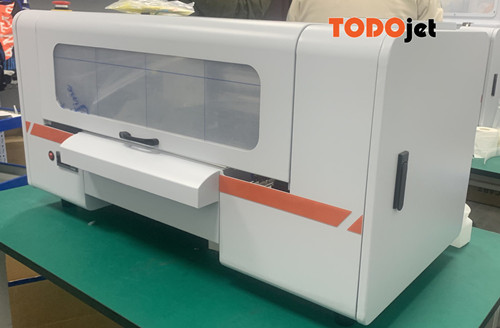

5. Short cycle and fast delivery time, breaking through the limitations of traditional color registration and plate making, digital output does not require plate making, and one piece is ordered

6. High cost performance, no need for high investment in equipment and space, greatly reducing investment costs