|

Model

|

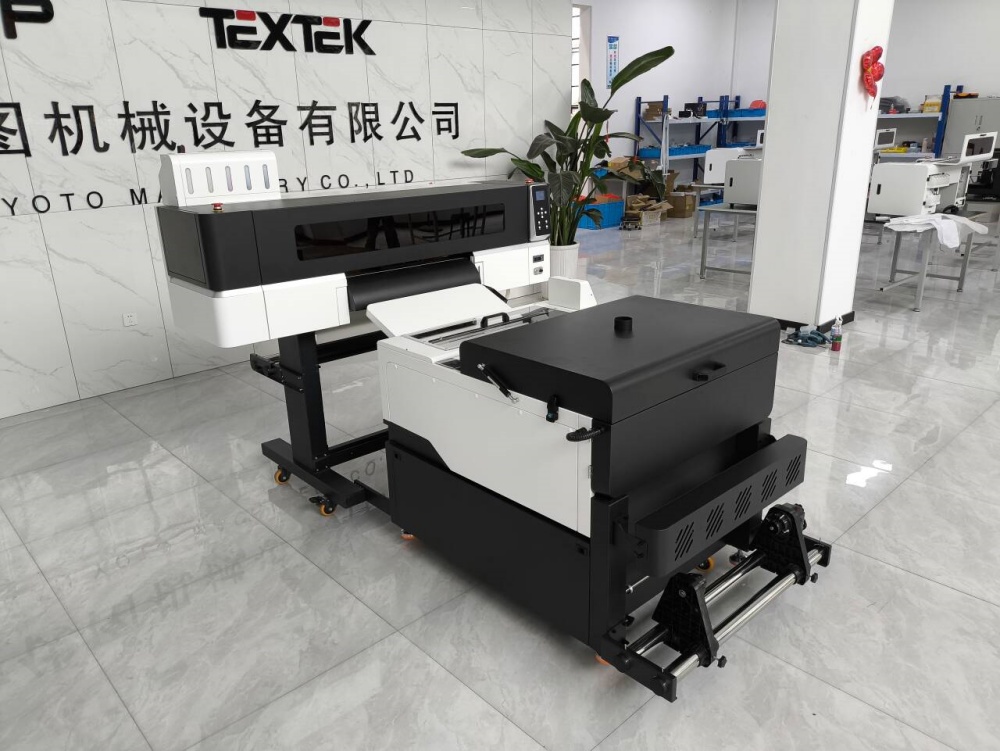

Shake powder machine H650 for dtf digital film printer

|

|

Available width

|

0-600mm

|

|

Applicable media

|

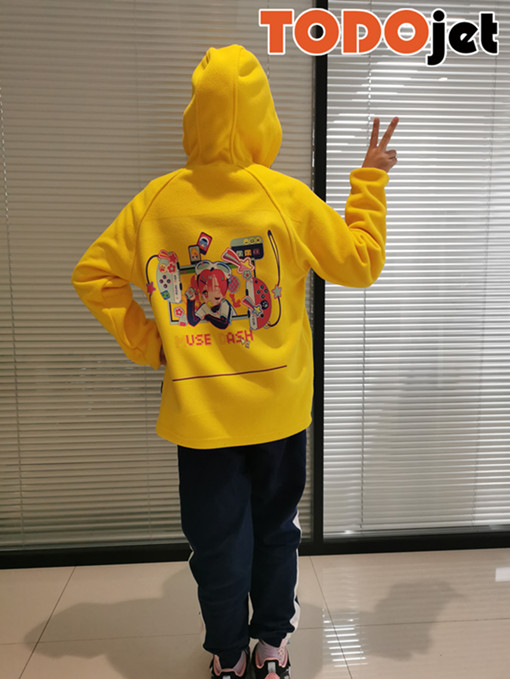

Nylon,chemical fiber,cotton,lether,swimsuit,diving suit,PVC,EVA.etc

|

|

Powder control

|

Powder shake control,powder and amout control.etc

|

|

Heat and dry function

|

Front heat plate,dry fixation,cold funs function

|

|

Take up function

|

Automatic inductive

|

|

Electrical parameters

|

Rated voltage 220v,Rated current 20 A Rated powder3.2KW Energy consumption1KW-2.5KW

|

|

Size&Weight

|

Machine size:1985*1090*1080MM/pacage size:1930*1120*1136MM Weight:260KG / N.W 180KG

|

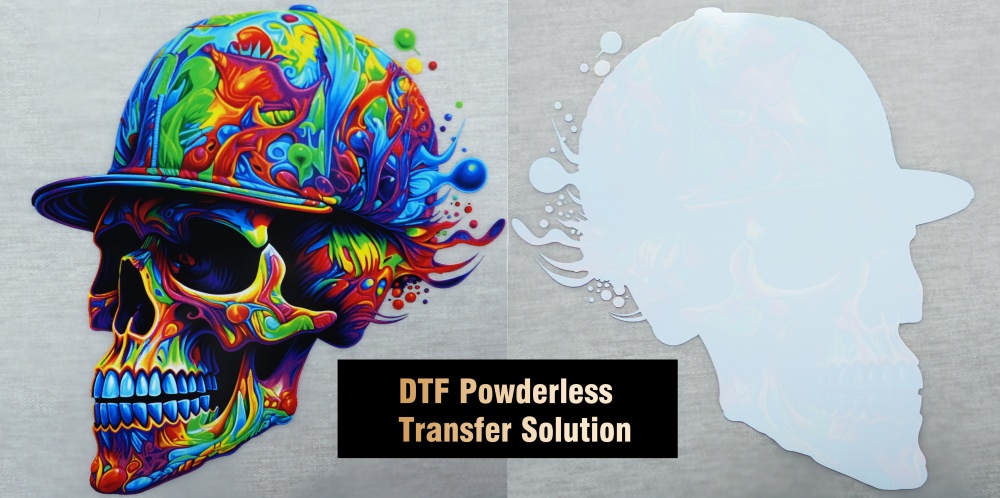

With the popularity of DTF Printer shaking powder machine will enter the line of sight together, simply put is an automatic hot melt powder machine, originally can be manually shaking powder and then heating, but with this shaking powder machine can automatically sprinkle powder, shaking powder, heating, drying, one-stop printing ironing finished products, improve the efficiency.

After the pattern is printed by the DTF Printer, the powder shaking machine is used to evenly shake the hot melt powder on the white ink part, and then heat and dry, and the finished hollow heat transfer can be printed directly. And it can be customized one by one, so it is very suitable for personalized heat transfer clothing customization.