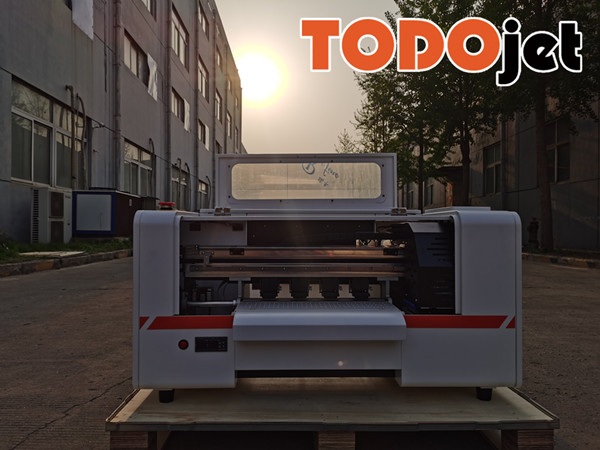

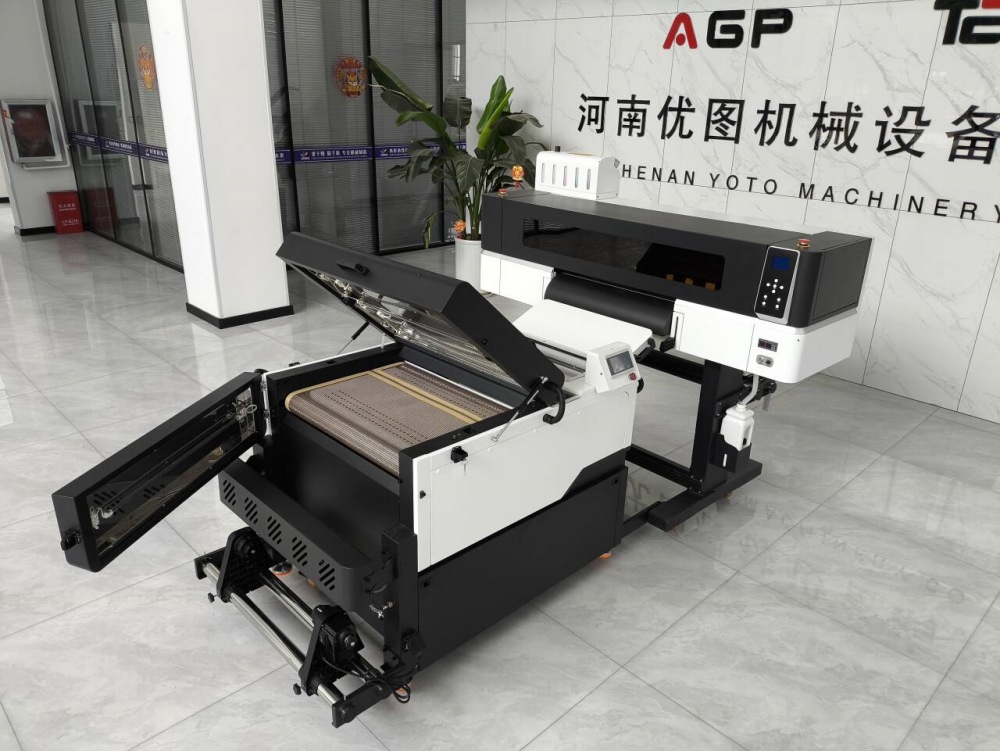

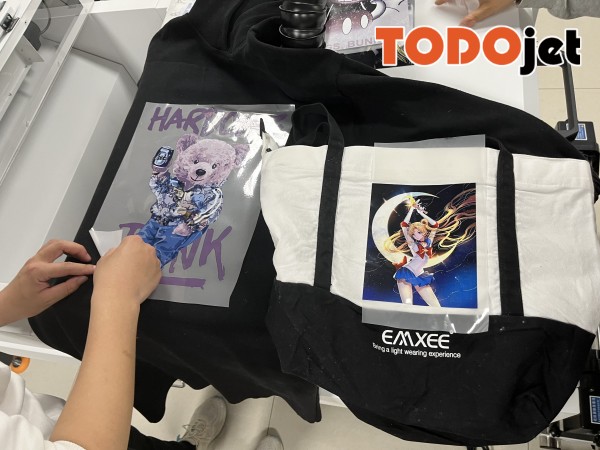

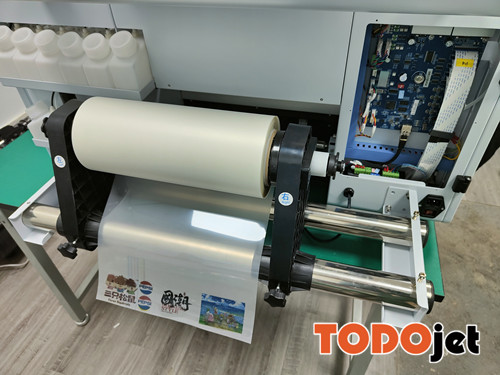

Small Digital A3 A4 30cm DIY Custom Heat Transfer DTF T-shirt Printing Machine PET Film Printer

White ink heat transfer printer is a kind of mechatronics precision equipment, the structure is generally more complex, compared with other external equipment of the computer, the failure rate is also relatively high, heat transfer printer printing disconnection is a common fault, generally caused by the following reasons .

White ink heat transfer printer is a kind of mechatronics precision equipment, the structure is generally more complex, compared with other external equipment of the computer, the failure rate is also relatively high, heat transfer printer printing disconnection is a common fault, generally caused by the following reasons .

1. After installing the new ink, basically only need to clean and print once or twice, the ink line can be normal, and generally it will not be broken during use. The reason for the disconnection is generally that the user did not set the paper feed bracket properly before printing, which caused the paper to be rolled during the paper feeding process, and the line was disconnected after the paper rubbed against the nozzle. The solution is to set the paper feed tray well.

2. The disconnection may also be caused by not replacing the new ink in time when the original ink is almost used up, but leaving the printer in a high temperature environment for a long time. After the ink is installed, it needs to be used up within three months. If the replaced ink is not used frequently, the air tightness will be deteriorated due to the effect of air entering the ink, which will easily make the ink on the nozzle and the viscosity of the ink increase. Thereby causing the failure of the heat transfer printer disconnection. The solution is to replace the ink directly, and then clean the nozzle to solve the problem.

3. The disconnection caused by the replacement of other brands of ink is because the performance of the ink does not meet the parameters required by the original ink of the printer. When replacing the ink of other brands, it is sometimes found that some colors are inked smoothly while some colors can only be released after many times of cleaning, which wastes a lot of ink. This is because the ink produced by such manufacturers may not meet the technical requirements of the original ink, and the problem of unbalanced ink delivery is easy to occur during use. The solution to this problem is to use original ink to solve the problem.