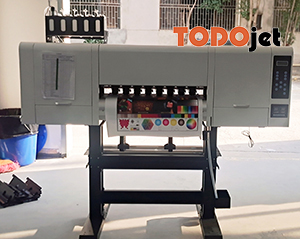

| Print head | 2pcs Epson XP600 heads |

| Print speed | 3-4.5sqm/h |

| Accuracy | 720*720dpi 4pass

720*1080dpi 6pass 720*1440dpi 8pass |

| Ink type | Pigment ink/Transfer film ink |

| Media Maximum Width | 32cm width |

| Media thickness | 1mm adjustable |

| Media type | PET film A3 size sheet / 30cm width roll |

| Heating system | Auto constant temperature drying system |

| Temperature | 160-170 cold/hot to tear |

| RIP software | Maintop |

| Power | AC110-220V, 50-60Hz, USB2.0, 350W |

| Operation environments | Temperature 20-30℃, Humidity 45%-65% |

| Machine size | 940*500*580mm |

| Packing size | 1000*640*640mm |

| Gross weight | 89kg |

| Max media | 30cm width |

| Heating size | 40cm |

| Voltage | 220V/5A |

| Power | 3.4kw |

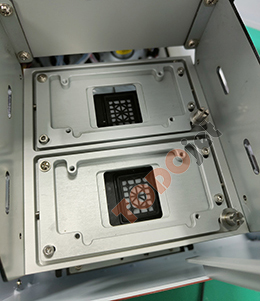

| Media transmission | New belt type |

| Take up function | Automatic inductive |

| Machine size | 850*650*600mm |

| Packing size/Weight | 790*610*710mm/50kg |