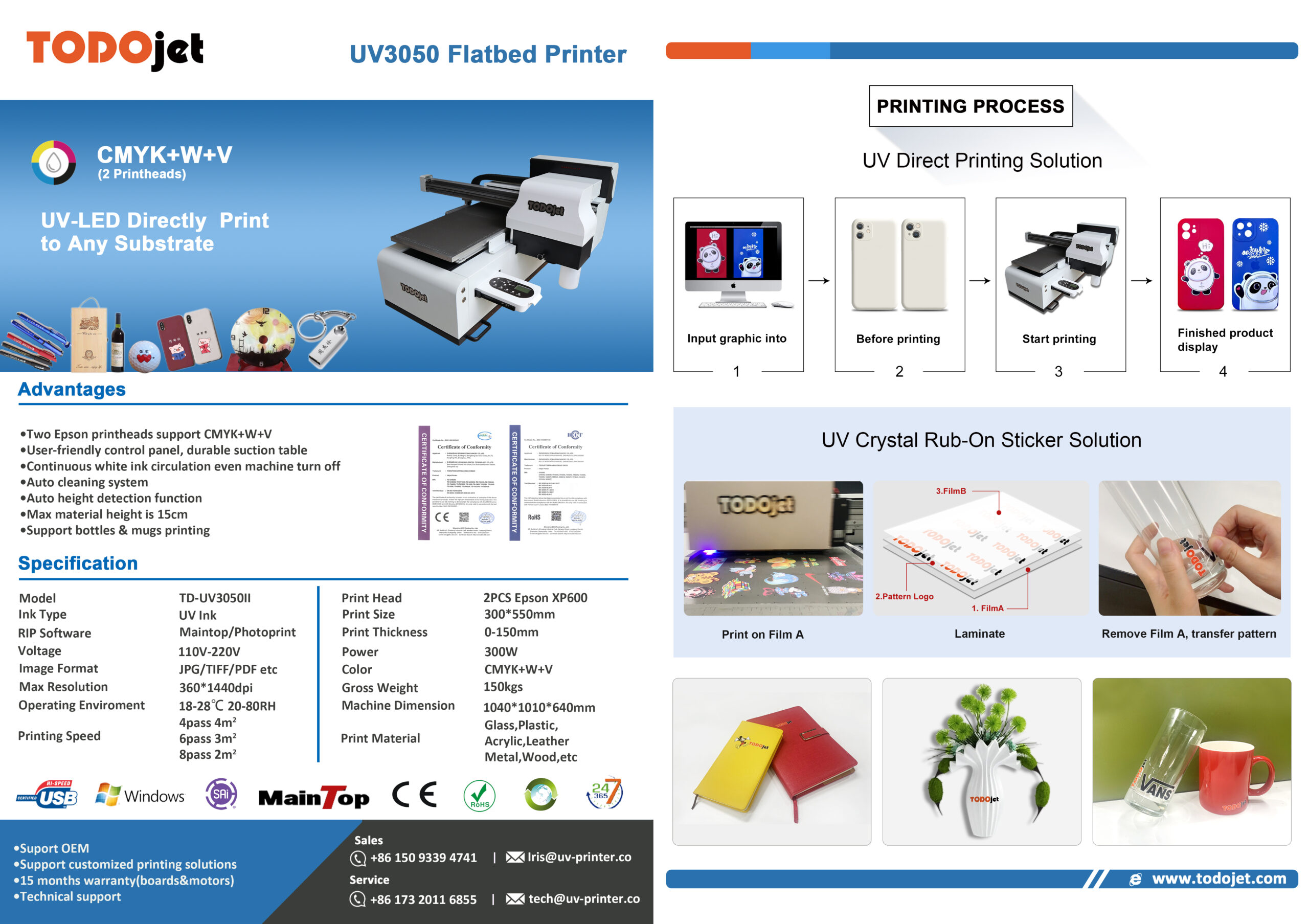

The main advantages of UV TODOjet Crystal Cold Transfer Sticker Digital Inkjet UV Dtf Transfer Film Printer

The main advantage of UV TODOjet Crystal Cold Transfer Sticker Digital Inkjet UV Dtf Transfer Film Printer

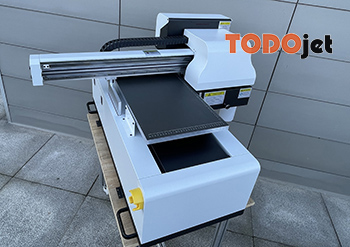

can be printed on almost any materials, surfaces and finished products

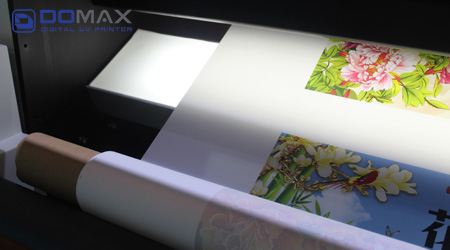

bright colors, high print detail

the ability to print on colored, dark and transparent products without color distortion and loss of brightness

high hiding power

presence of white ink and varnish

the ability to print varnish selectively, creating the desired accents

the ability to print on finished products with a height (thickness) of up to 10 – 15 cm, and sometimes more

the ability to print on cylindrical products (with additional equipment)

high abrasion resistance, high strength of the ink layer

the ability to print on flexible materials such as leather, canvas, eco-leather

no additional post-printing required

products can be used immediately after printing

can be used inside interiors (including ink with appropriate certification)

the cost does not depend on the volume of circulation

direct printing of an image from a computer to a product without the use of intermediate media

short production cycle – a few minutes from launch to print to receipt of the finished product

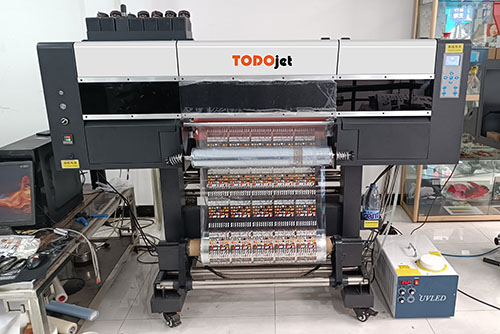

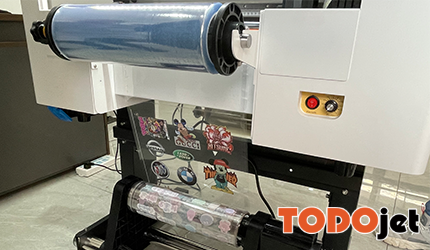

2021 new technology can break the limit of material shape and height, printing on film and transfer on any hard material you want

The main advantage of UV TODOjet Crystal Cold Transfer Sticker Digital Inkjet UV Dtf Transfer Film Printer

- can be printed on almost any materials, surfaces and finished products

- bright colors, high print detail

- the ability to print on colored, dark and transparent products without color distortion and loss of brightness

- high hiding power

- presence of white ink and varnish

- the ability to print varnish selectively, creating the desired accents

- the ability to print on finished products with a height (thickness) of up to 10 – 15 cm, and sometimes more

- the ability to print on cylindrical products (with additional equipment)

- high abrasion resistance, high strength of the ink layer

- the ability to print on flexible materials such as leather, canvas, eco-leather

- no additional post-printing required

- products can be used immediately after printing

- can be used inside interiors (including ink with appropriate certification)

- the cost does not depend on the volume of circulation

- direct printing of an image from a computer to a product without the use of intermediate media

- short production cycle – a few minutes from launch to print to receipt of the finished product

- 2021 new technology can break the limit of material shape and height, printing on film and transfer on any hard material you want

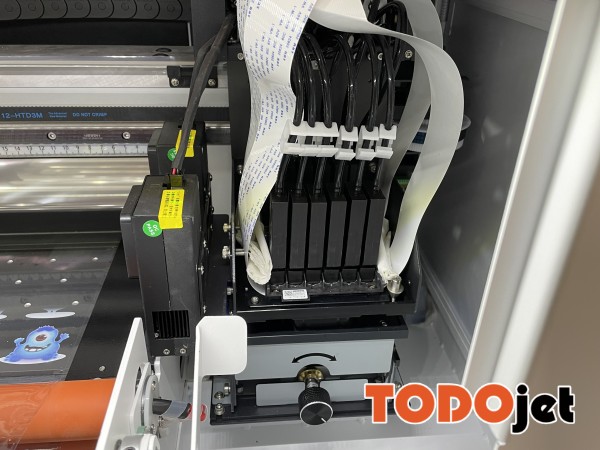

Reasons and Solutions for No Ink from Nozzle of UV Flatbed Printer

There are 8 reasons for the failure of the uv flatbed printer, which will inevitably occur during the use of the equipment. According to the differences in the design of uv flatbed printers from different manufacturers, there may be 10 reasons. There may be 6 different reasons. However, mastering the following 8 types can solve 99% of the failures of the nozzles not producing ink.

1. Negative pressure is not within the working range

The negative pressure value of the uv flatbed printer needs to be adjusted to return to the normal range. (In view of the different fluctuations in the added value range of equipment of different manufacturers, it needs to be recorded in advance for later use), you can choose manual mode or software automatic mode.2. Problem with ink supply

Check whether the uv ink itself is expired, condensed, or has quality problems, which will cause the print head of the uv flatbed printer to not ink. If these phenomena occur, you can replace it with a new one by yourself.3. The ink path and nozzle are blocked

When the ink path and print head are seriously blocked, it needs to be cleaned with a special cleaning solution. It can be judged that the blockage problem has been solved according to the bead-like lines ejected from the print head of the uv flatbed printer. It is recommended to replace the ink tubes with new ones about 6 months .4. The software printhead temperature is missing

Check whether the heating device of the printhead of the uv flatbed printer is normal. If the device itself does not have this device, an external heater, heating fan, etc. can be installed to ensure that the printhead of the printhead is within the normal working range.5. The software printhead voltage is missing

If the printhead is burnt, it needs to be replaced with a new printhead; if the printhead board is faulty, you can contact the original UV flatbed printer manufacturer and ask them to send a new printhead voltage board to replace.6. The nozzle communication is missing and the network cable is loose

Check whether the flat line of the uv flatbed printer nozzle and the position of the interface are loose, broken, etc., and replace it with a new one.7. The nozzle is damaged

You can only replace the new uv flatbed printer nozzle. Remember that the equipment must be grounded, must be independent of the power supply, and must be equipped with a voltage stabilizer.8. Printhead board failure

The failure of the printhead card will cause the UV flat printhead to fail to discharge ink. This situation can be reported to the manufacturer, and the card is within the scope of the warranty.