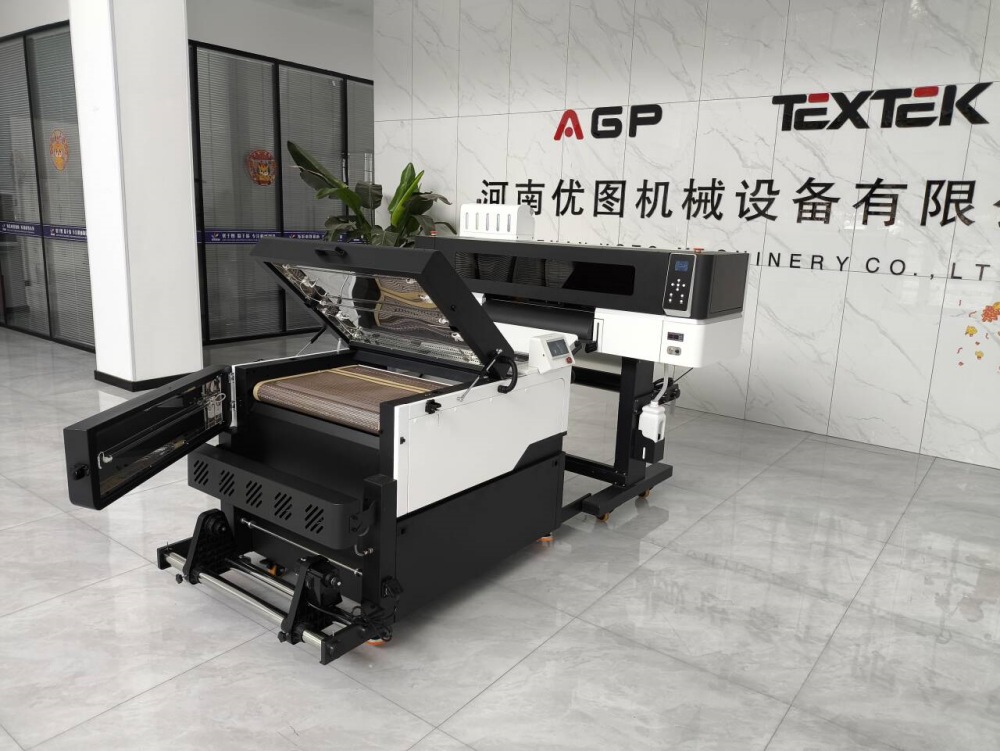

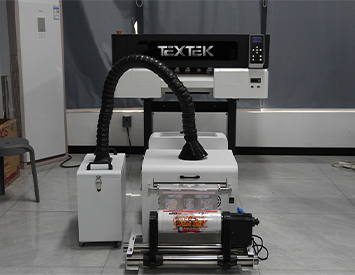

todojet 12″ DTF Printer and Dryer / Shaker Complete System

Be productive with TODOjet DTF printer textile transfers. Cover a wide range of products like t-shirts, polos, bags, pet clothing, and even small logos in specific places (sleeves, pockets, etc.). Gain numerous applications

Multiply your productivity

Avoid pretreatment on polyester and save time. Print multiple small designs on a TODOjet DTF printer transfer film and heat press them on different applications within minutes. Allow your customers to pick and choose between a large variety of ready-to-transfer designs. It’s now simple to reduce your production time!

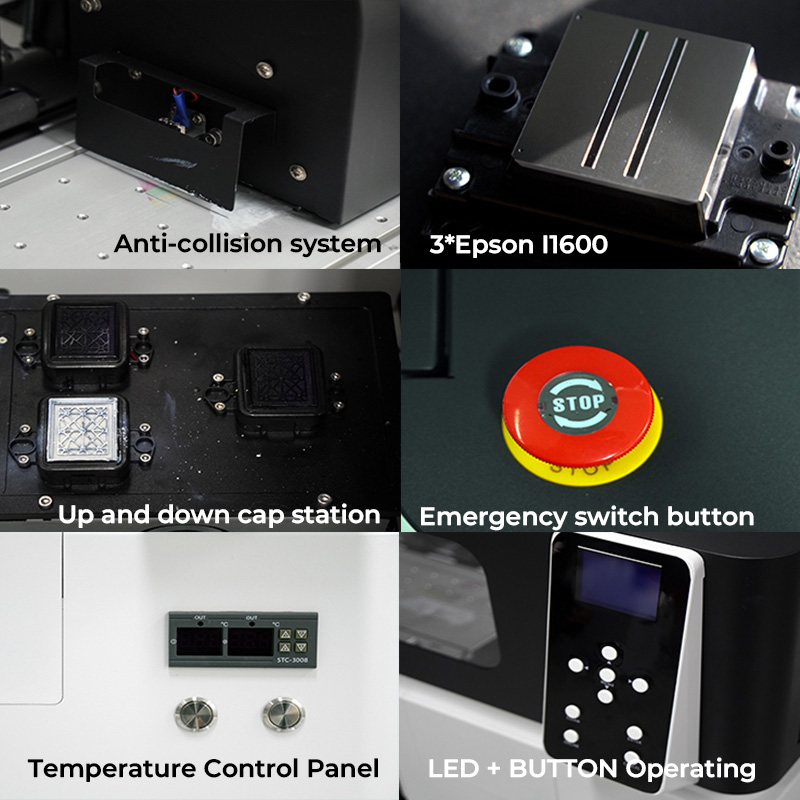

?What are the parts of the DTF printer?

•Ecotank. The container where the ink tanks are located.

•Waste ink tank. Temporary storage for your ink waste.

•Dampers. Cartridges are located above the printhead.

•Printhead. Transfers an image onto the print media.

•Capping station. This is where the printhead flushes the waste ink.

•Wiper blade. Rubber attachment that cleans the head when it comes out of the capping station.

| Print head | 2pcs Epson XP600 heads |

| Print speed | 3-4.5sqm/h |

| Accuracy | 720*720dpi 4pass

720*1080dpi 6pass 720*1440dpi 8pass |

| Ink type | Pigment ink/Transfer film ink |

| Media Maximum Width | 32cm width |

| Media thickness | 1mm adjustable |

| Media type | PET film A3 size sheet / 30cm width roll |

| Heating system | Auto constant temperature drying system |

| Temperature | 160-170 cold/hot to tear |

| RIP software | Maintop |

| Power | AC110-220V, 50-60Hz, USB2.0, 350W |

| Operation environments | Temperature 20-30℃, Humidity 45%-65% |

| Machine size | 940*500*580mm |

| Packing size | 1000*640*640mm |

| Gross weight | 89kg |