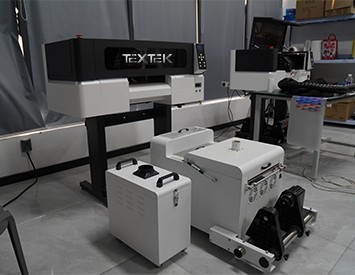

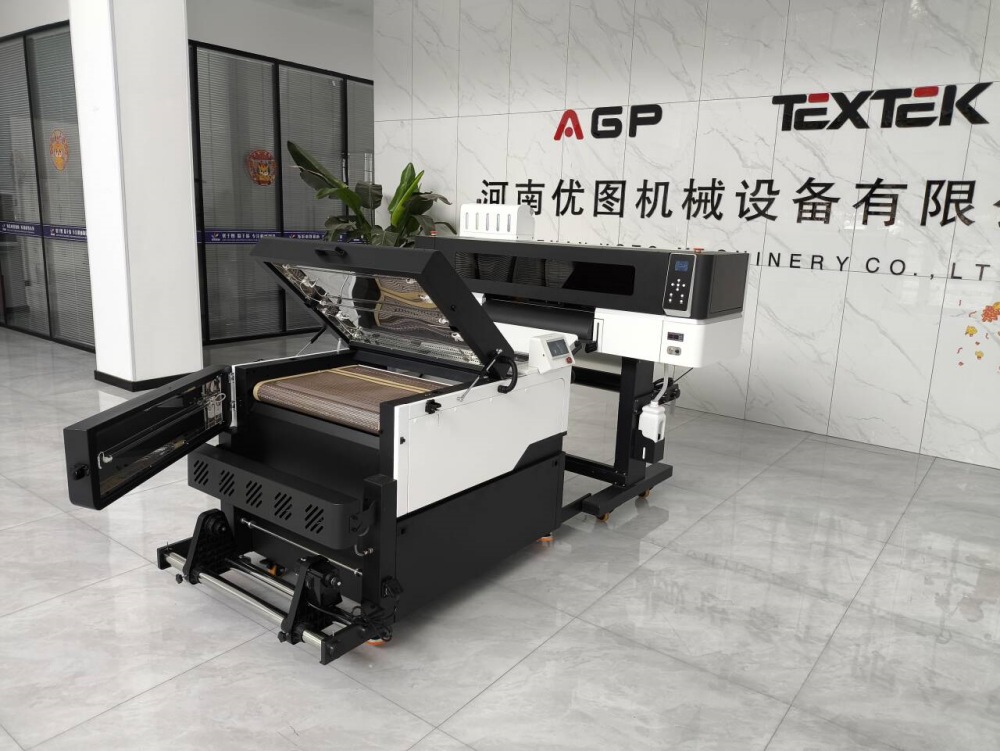

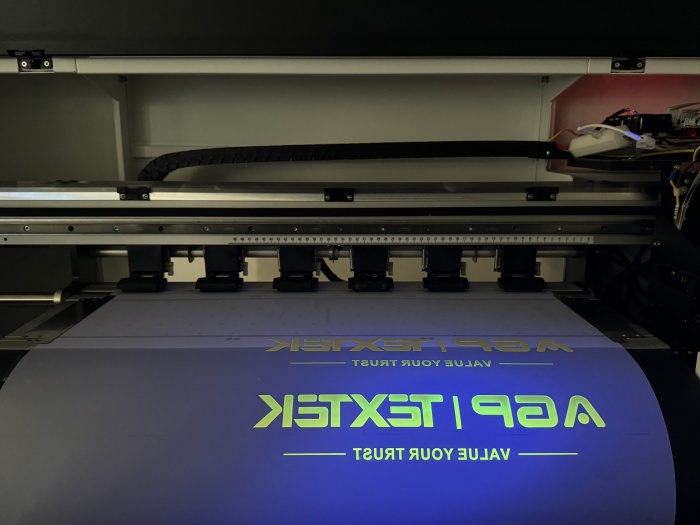

TODOjet A3 DTF Printer – Professional Direct to Film Printer

Differences between DTF, DTG, and White Toner printing

We could say that DTF printing combines DTG printing and white toner. That’s why comparing them can be a little bit confusing. Let’s analyse their differences to help you find the technique that best suits your needs.

Contact US

Get Price

Share:

Content

DTF vs DTG printing

The abbreviations DTF and DTG are very similar, and both techniques use an inkjet printer with white ink. How are they different?

- The investment: DTF printing requires a very low investment compared to the cost of a DTG printer. A DTF kit costs almost one-tenth of the price of a DTG printer.

- Production time: DTF printing starts by printing a design on a film. You must then add DTF powder to it. The printed film will then have to be cured, and the design transferred from the film to the fabric. With DTG printing, the printer prints directly onto the garment, which reduces production time significantly compared to DTF printing.

- Print touch and finish: DTF has a slightly “plastic” finish, very similar to HTV or screen print transfers. However, the inks are very elastic, which prevents the print from cracking when the garment is stretched. With DTG printing, the ink is completely absorbed into the garment, resulting in a much finer finish and better integration with the fabric.

- White intensity and purity: in this case, DTG printing produces a purer and more intense white. In the case of DTF, white isn’t as pure and intense.

- Consumable costs: both techniques have low production costs. Although it may seem that DTF printing is more expensive because it uses more supplies in the printing process, the final cost of a T-shirt printed with this technique is slightly lower than that of a T-shirt printed using DTG printing.

DTF Printing vs White Toner

The similarity here lies in the production process, as you must print the design before transferring it to the T-shirt. The result is also very similar in feel. Let’s analyse the differences between T-shirt personalisation using DTF printing and low-cost white toner.

- The investment: a DTF kit costs less than a laser printer, about half the price of a Uninet or OKI laser printer.

- Printing process: DTF is much simpler than white toner, as the white layer is printed at the same time as the colour layer (compared to low-cost white toner systems).

- Weeding FOREVER NO CUT transfers: with the white toner technique, you will need to press the printed paper A onto paper B to add the adhesive and weed it. This step is the most delicate because the transfer could be damaged and cause expensive production losses if it isn’t done properly. With DTF printing, this step doesn’t exist, saving you time and money.

- Print touch and finish: the finish has almost the same feeling as the touch for both techniques. The main difference is that DTF inks are textile and provide greater elasticity and wear resistance.

- White intensity and purity: in this area, white toner provides a more intense white colour.

- Consumable costs: white toner has much higher printing costs than DTF printing because of the toner and NO CUT transfer papers required for its application. A personalised T-shirt printed with a DTF printer has a 50% lower production cost than a T-shirt printed with white toner.

- Different projects possible: DTF printing is a technique that can be used mainly on textiles, whereas white toner laser printing opens up a wide range of possible projects. In addition to this type of product, it is also possible to personalise rigid objects in colour.

Inquiry

More DTF Printer