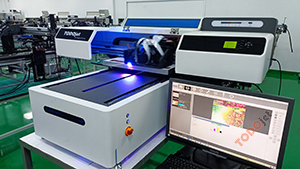

UV flatbed printer installation site requirements

UV flatbed printer installation site requirements mainly include seven aspects, which are light, temperature, airflow, power supply, wiring, ground, and dust requirements. During the installation process, strictly follow the standards to ensure the smooth installation and use of the machine.

1. Ambient light requirements:

UV ink contains UV curing agent. Natural light in the working environment or LED UV light will cause the ink to solidify. In order to extend the life of the print head, UV flat printers need to take measures to avoid natural light exposure on site. Incandescent lamps or LEDs can be used as the light source on site.

2. Environment temperature requirements:

The recommended temperature for the storage and use of UV ink is 15 to 25 degrees Celsius, and the humidity is controlled from 40% to 70%. Avoid fire sources and high heat environments. Pay attention to the safety of the storage and use environment.

3.Environment airflow requirements:

UV ink will have a slightly irritating odor. Please take good ventilation measures in a closed environment. If auxiliary heating or air circulation equipment is on site, the air flow generated by such equipment cannot be directed to the UV flatbed printer table.

4, environmental dust requirements:

Excessive dust and swarf in the working environment of UV flatbed printers may cause board circuit failures and nozzle blockages, which will seriously cause ink dusting, affect printing results and damage the nozzles. Please do on-site cleaning.

5.On-site power requirements:

The uv flatbed printer should provide a standard AC voltage of 220V / 50HZ on site, and the voltage requirement should fluctuate less than 2.5%. The line should include a reliable ground wire and the resistance of the lead to ground should be less than 4 ohms. Need to be equipped with an independent power system, can not be mixed with other equipment.

6. On-site wiring requirements:

Please use wire trunking uniformly for field wiring of uv flatbed printers, and equipment communication and power lines must not be stepped on. If you go to the ground, you need to install a special protective shell on the line to avoid the wire skin from abrasion and leakage after a long time.

7.Ground requirements:

The floor where the UV flatbed printer is installed should be flat, and no landslides, depressions, etc. should occur, which will affect the normal operation of the equipment in the later stage.