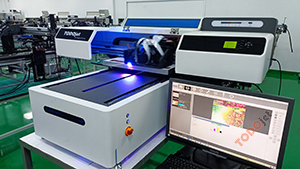

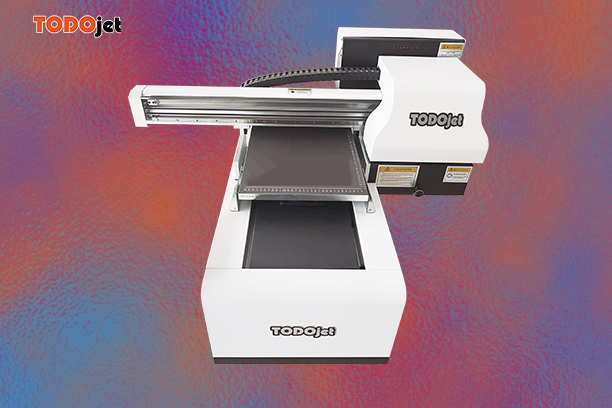

UV flatbed printer safety equipment requirements

UV flatbed printer safety equipment mainly includes three aspects: Electrical connection, ground wire, and mobile machine. Each part must be installed and banned accordingly. It must be strictly observed to prevent safety accidents.

UV flatbed printer safety equipment requirements:

1.UV flat printer is connected to 220V AC power, current 10A, maximum power 750W;

2. It is required that the voltage regulator is suitable for the voltage of the UV flatbed printer: basically refer to the maximum power of the equipment 750W for selection. It can play a regulating role when the unstable voltage is in order to prevent the unstable voltage from causing damage to electronic components in the circuit system;

3.UV flatbed printer must be connected to the ground wire to provide a low-impedance connection between the equipment and the ground body to reduce the risk of personal injury from electric shock;

4. Environmental requirements: Temperature requirements are 15-25℃, humidity requirements are 40% -70%, and there is no dust. When the temperature is lower than 15 degrees, the viscosity of the ink will increase, and the smoothness is not good. When printing, there will be other unknown phenomena such as broken ink, virtual needles and so on. Excessive dust will greatly damage the print head. Excessive humidity will affect the adhesion of the ink;

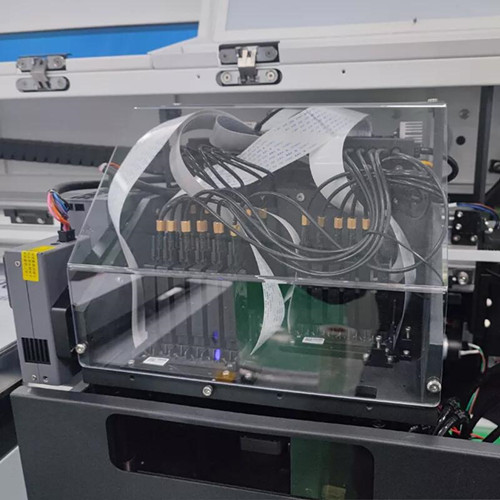

5. The computer is equipped with a mechanical hard disk of more than 500G, running memory of more than 4G, 1G independent display, CPU I3 or I5; if necessary, an additional solid-state hard disk 120G can be added. Ensure that the software and hardware required for UV flatbed printers to run without obstacles to meet the needs of storage and operation;

6. Please remove all external circuits when moving the UV flatbed printer, and make marks and take photos for the retention, remove the external device connection, and make marks and take photos for the retention. After receiving the machine, contact the manufacturer’s technical staff, and refer to the installation Installation, can also be handled by the following methods: telephone guidance, home repairs, etc .;

UV flatbed printer safety equipment prohibition:

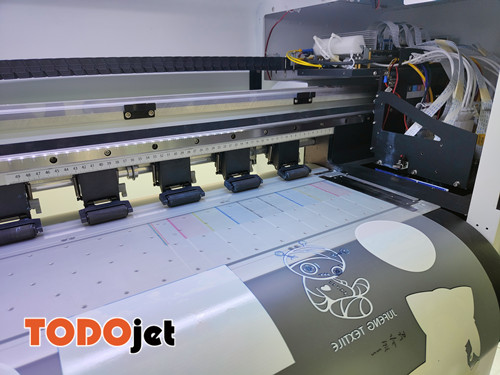

1. It is forbidden to prevent items in the moving part of the carriage board and turn on the print mode: this will cause a strong impact and damage the nozzle;

2. It is forbidden to touch the moving part of the carriage board in the print mode: because this will cause serious accidents and injuries;

3. It is forbidden to prevent articles on the moving part of the beam and enable printing mode: this will cause strong impact and damage the nozzle;

4. It is forbidden to touch the moving part of the beam in the print mode: this will cause serious accidents and injuries;

5. Children are not allowed to play near the device: during the operation or non-operation of the device, the device product has a high-speed movement or standby state. Once the switch is touched, it will cause serious accidents and injuries;

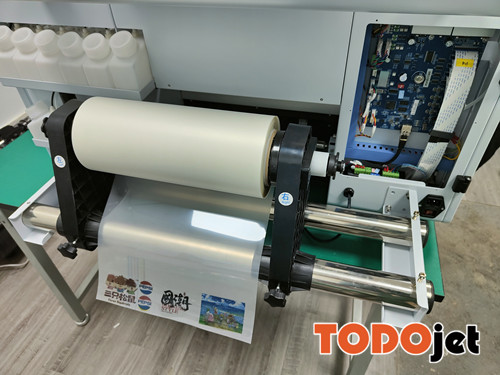

6. It is forbidden to discard waste products containing ink mixtures in consumable lamps. They can be stored uniformly and delivered to the waste recycling processing station for unified processing. Be sure to turn off the secondary cache cartridge after shutdown: otherwise, the next time the device is turned on, a series of Problems, serious failure to boot;

7. It is forbidden to modify or replace other accessories: the modification or replacement of other accessories will cause the UV flatbed printer to fail to operate normally. If the input power supply is not clear, it will lead to accidents, injuries, serious and even fire;

8. It is forbidden to choose different types of consumables for use: replacing consumables of different brands or models will result in improper printing and severely cause nozzle blockage;

9. It is forbidden to use 380V three-phase power access, which will cause all equipment of the equipment to be burned.