UV printer 6 coating usage methods and storage matters

Although UV printers can print patterns on the surface of hundreds or thousands of materials, due to the characteristics of the surface of different materials, the adhesion of UV ink, flexibility and other performance differences, it will lead to peeling, peeling, etc. on some materials. situation, which requires the use of UV coating to solve this problem.

UV printer 6 coating usage methods and storage matters

Although UV printers can print patterns on the surface of hundreds or thousands of materials, due to the characteristics of the surface of different materials, the adhesion of UV ink, flexibility and other performance differences, it will lead to peeling, peeling, etc. on some materials. situation, which requires the use of UV coating to solve this problem.

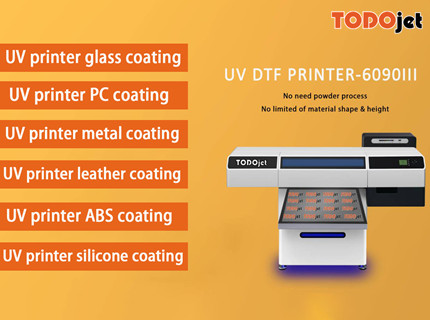

There are 6 types of UV printer coatings commonly found on the market:

1. UV printer glass coating:

It is suitable for plexiglass, tempered glass, glazed tiles, crystal and other glass materials that require special treatment. Currently, there are two types of quick-drying coating and baking. The former can be printed after wiping and standing for 10 minutes, and the latter It needs to be baked in the oven before printing the pattern.

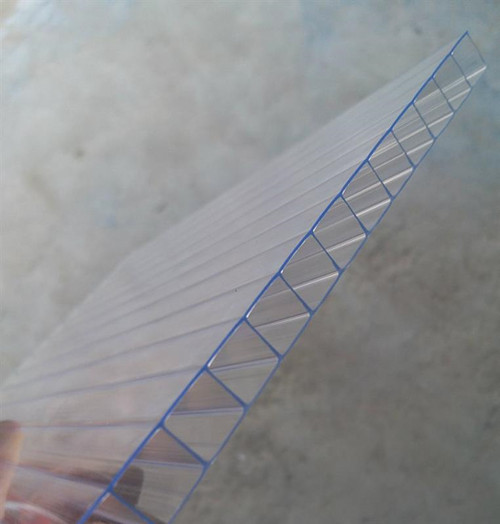

2. UV printer PC coating:

There are some hard PC materials, which usually have poor adhesion! Some PC materials are directly printed without coating! Generally, the imported PVC acrylic sheet needs to be wiped off the PC coating.

3. UV printer metal coating:

Metal coating: suitable for aluminum, copper plate, tinplate, aluminum alloy and other materials, there are two kinds of transparent and white, it needs to be used on the finished product, not before stamping and injection molding, otherwise the effect will be greatly reduced.

4. UV printer leather coating:

It is suitable for leather, leather, PVC leather, PU leather, etc. After spraying on the surface of leather material, wait for it to dry naturally.

5. UV printer ABS coating:

It is suitable for wood, PVC, ABS, gypsum, thickened kraft paper, acrylic, PS PVC and other material surfaces. After wiping the coating, it can be printed naturally after drying.

6. UV printer silicone coating:

![]()

Suitable for silicone, rubber material. Poor surface activity, flame treatment is required, otherwise the adhesion is not enough, flame treatment is based on experience, the surface should not be sprayed too thick, otherwise it will not be easy to dry.

Instructions

1. The formulations required for the coating have a fixed proportion and stirring skills, which must be carried out in accordance with the instructions;

2. Once it is found that the coating has a chemical reaction such as dissolution and foaming with the UV ink, it is necessary to replace the coating with better compatibility;

3. The irritating odor of the coating is generally relatively large, and masks and disposable gloves can be matched during the operation;

4. The types of coatings corresponding to different materials are also different. Do not use one coating to match other materials.

Preservation of the coating

1. Place in a cool and ventilated place with backlight;

2. After use, the bottle cap should be tightened in time;

3. Do not press other materials on it;

4. Do not put the coating liquid on the ground, but choose the shelf.

Usually when a user buys a UV printer, the manufacturer will provide a matching coating, mold or varnish and other process solutions according to the user’s product characteristics.