What are the garment printing techniques?

Printing process is the process of printing the pattern on the textile with dye or pigment.Prinints are fabric printing, wool printing and yarn printing.Sool printing is used to make mixed flowers; yarn printing is used to weave colorful fabric.Fabric printing has a long history.The common process includes direct printing, anti-dye printing and undyeing printing.There are other local printing, full-body printing, water-based pigment printing, jelly printing, hot-fixed ink printing, transfer printing, special coating printing, special process printing, etc.

There are other local printing, full-body printing, water-based pigment printing, jelly printing, hot-fixed ink printing, transfer printing, special coating printing, special process printing, etc.

- Anti-dyeing printing

Anti-dye printing is a material that is first printed on the fabric to prevent the dye, and then stained or colored to obtain a pattern on the dyed fabric.

- Dial printing

Printing printing is the printing process of printing the dyeing fabric to eliminate the substance of the dyeing dye and obtain the pattern on the dyeing fabric.

- Direct printing

Direct printing is directly printed on the white or light color fabric first with dye or pigment, and then after steaming and other processing to obtain the pattern, the process is short, widely used.

- Gelatin printing

Pulp printing-the emergence and widespread application after water slurry.Because of its coverage is very good, so that the dark clothes can also be printed on any light color, and have a certain gloss and stereo sense, so it can be quickly popularized.

But because it has a certain hardness, so it is not suitable for large areas of field patterns.So it is better for the combination of water and jelly to solve the problem of large-area printing.

- Hot-solid ink printing

Hot fixed ink printing is suitable for all kinds of fabrics (including chemical fiber), is a more development prospect of printing ink.Because it is suitable for advanced computer design, adapted to the use of modern automatic production, symbol the trend of contemporary technology.Especially in the dark fabric print net pattern, its effect is incomparable to the jelly.

- Transfer prints

Transfer printing mainly has hot melt glue type and deink permeable type two kinds.First use the printing method will be the pigment on the paper, make into transfer printing paper, and then transfer the color through high temperature (heating and pressure on the back of the fabric), generally used in chemical fiber fabrics.

- Local printing

Local printing is to be printed in a small part of the clothes, the parts are mainly: predecessor, back, front and left upper chest, cuff, back priority and lower, etc.

- Print all over

Full prints are cloth prints, cut prints and garment prints.Among them, the full garment full printing needs to be produced by a special clothing printing machine, which currently represents the higher technical equipment level of clothing printing.

- Water-based pigment printing

Waterborne pigment printing, called water slurry, is a kind of water-based slurry.It is printed on the clothes feel is not strong, the coverage force is not strong, only suitable for printing on the light-color fabrics, the price is relatively flat, it belongs to the lower grade printing category.But it also has an advantage, because it will not affect the original texture of the fabric, so it is more suitable for a large area of printing patterns.

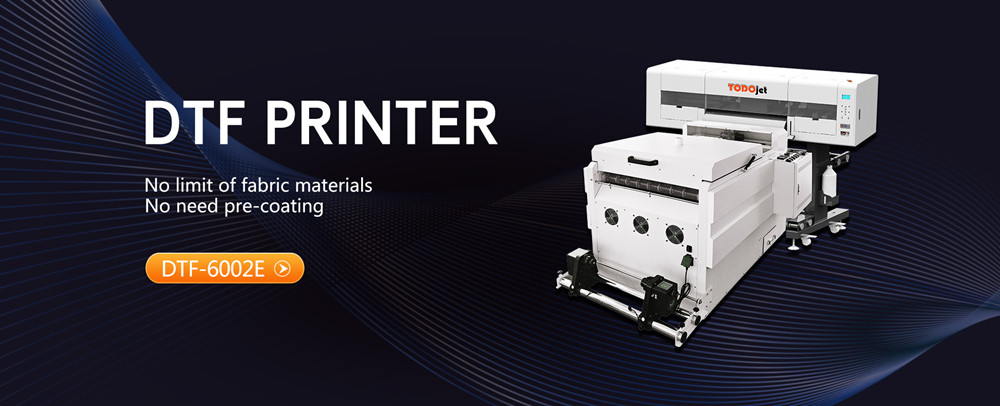

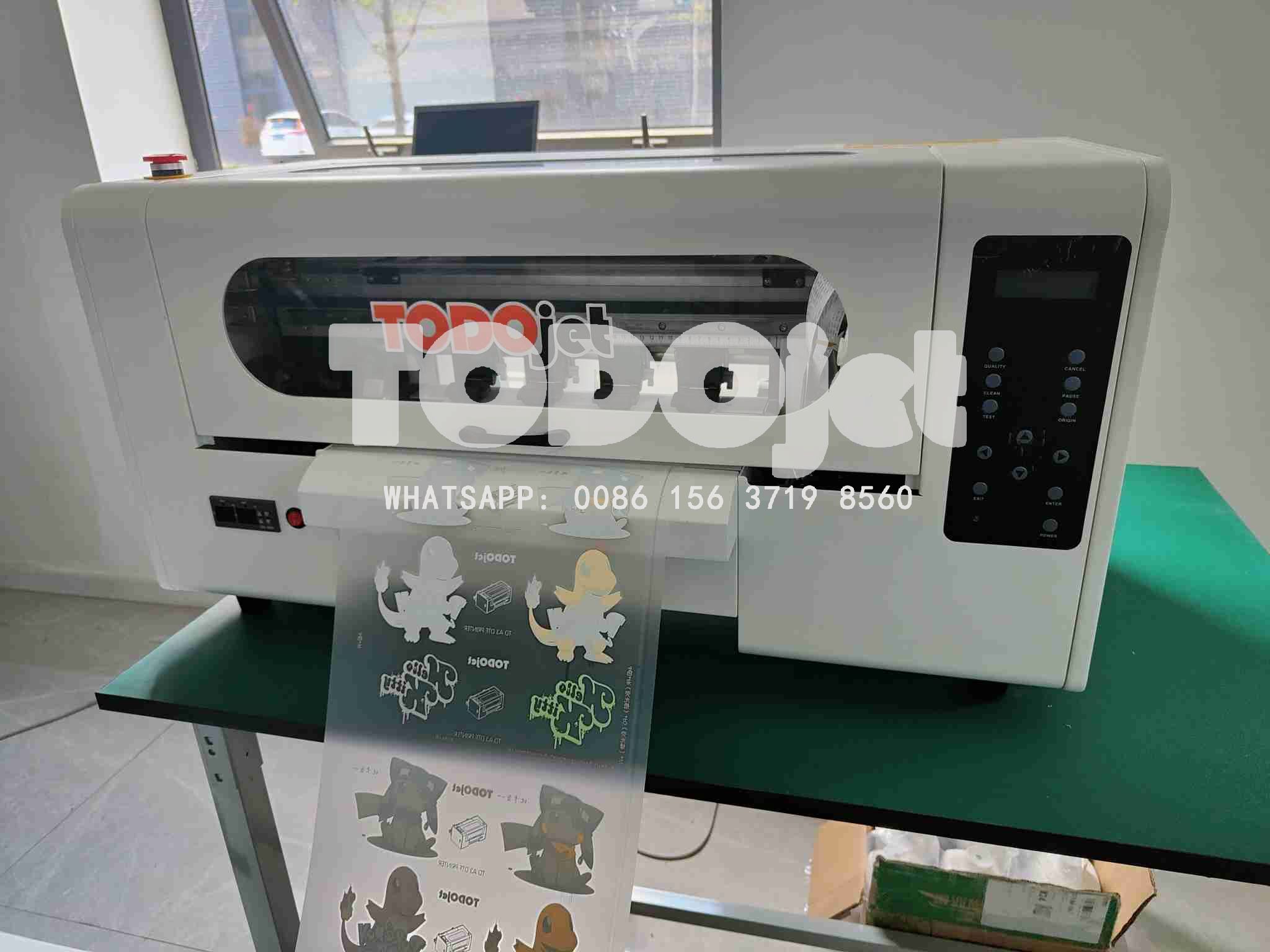

We have DTF printers. That is Dtf Heat Transfer Printer.

A3 DTF printer A1 DTF printer

Advantages:

No limit of fabric materials

No need pre-coating

No need plate making

No need contour cutting

Environment-friendly pigment ink

Small invest, large benefit