What do you need for DTF printing?Something about DTF PRINTING FAQ

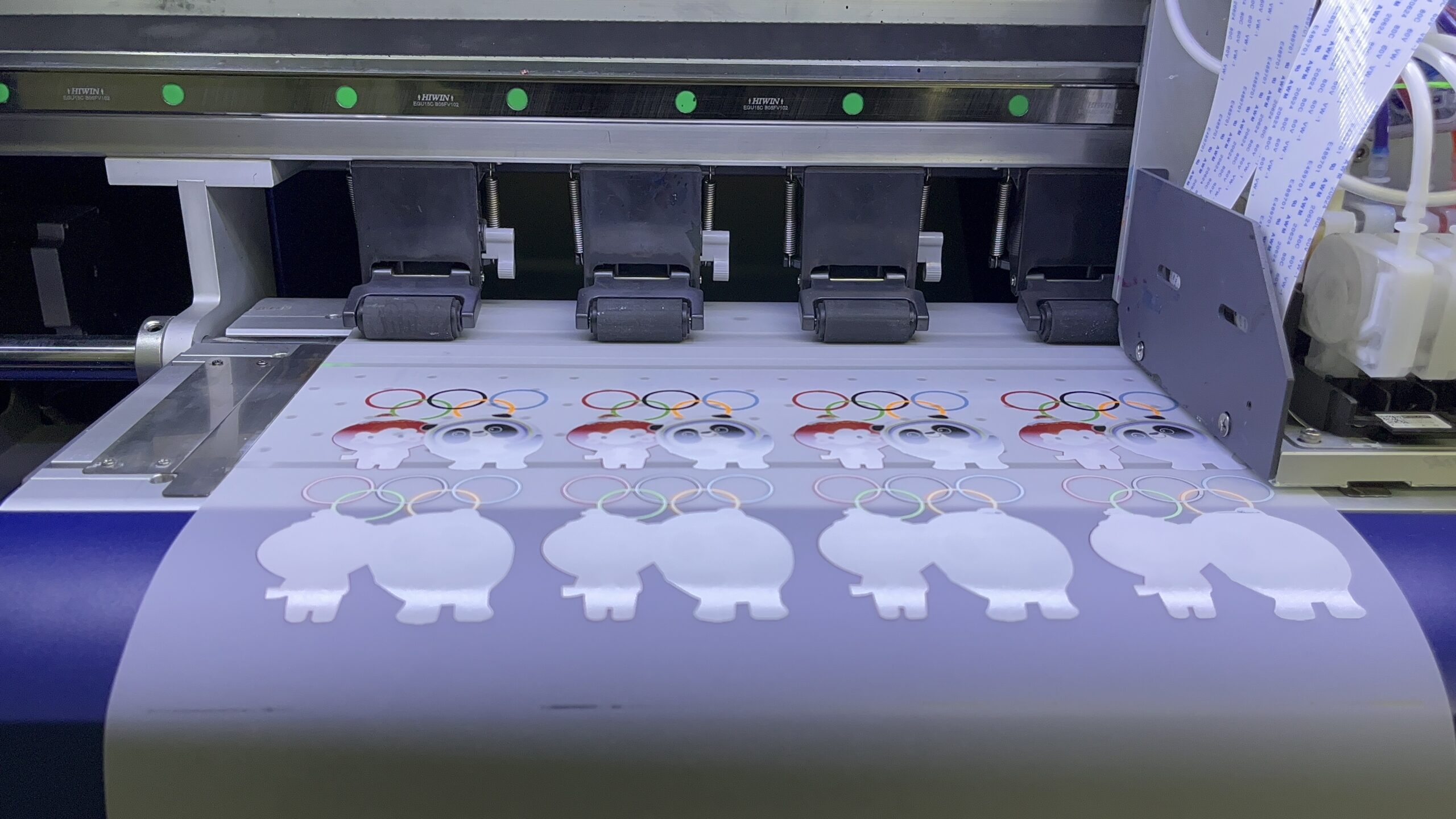

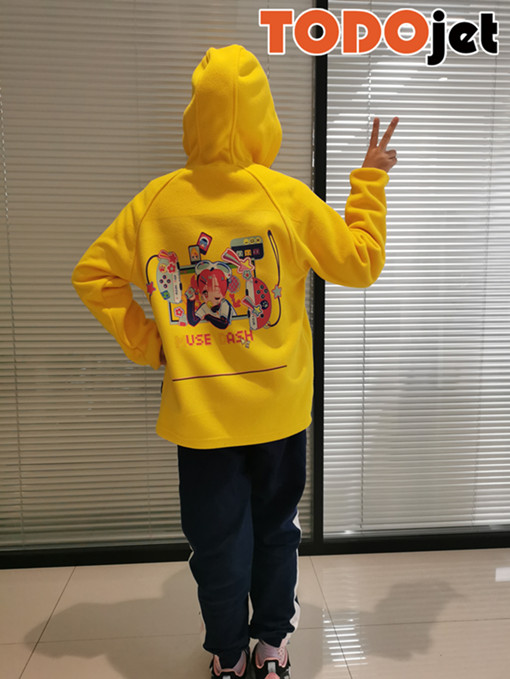

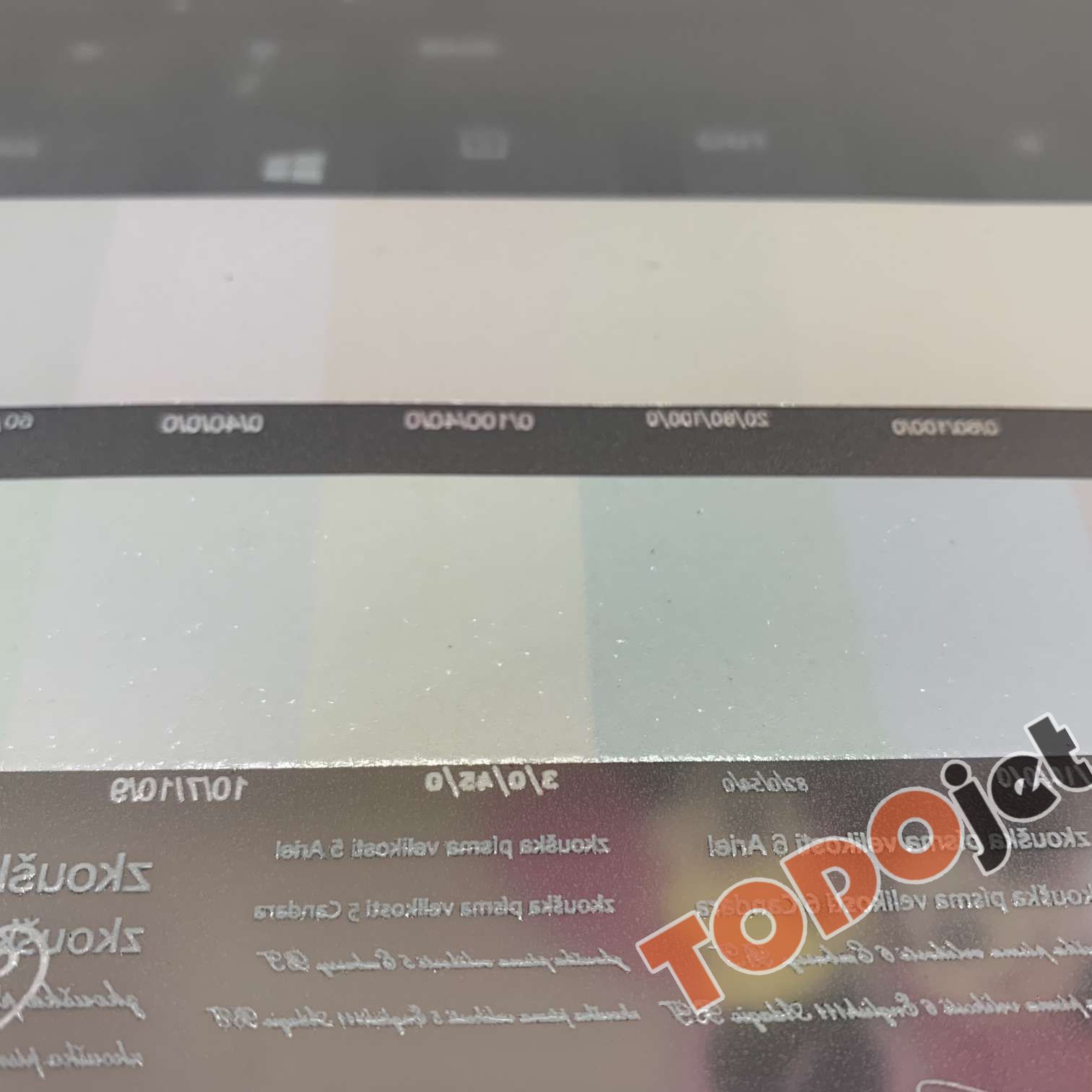

The DTF printing must be printed on a special transfer film, hot melting powder on the back of the PET film, pressed into the clothing and peeled off the film if it is cold. The DTF Printers are so popular. The following is something about DTF Printer you’d better know.

Content:

Pre-requisites for DTF Printing

- Direct to Film Printer. These printers are often called DTF Modified Printers.

- PET films are used in the DTF printing process.

- The software is an important part of the process.

- Hot-melt adhesive Powder.

- DTF Printing Inks.

- Automatic Powder Shaker.

- Curing Oven.

- Heat Press Machine.

Q: Does DTF printing require a lot of printer maintenance?

A:DTF printing still requires the same maintenance that DTG needs. Just not as often. DTG ink does not clog up as bad and when clogs do happen, they are a lot easier to clean. DTF white ink still separates and will need a daily shake. Best form of maintenance is regular printing. If you print every 2 days, all you will need to do is shake the ink and run an automatic printhead clean before printing.

Q:Can I print on DTF film with DTG ink?

A:No, DTF printing requires special DTF ink. Printing with DTG ink on DTF film will make the ink run and mix with white and CMYK.

Q:Can I put DTF ink into my DTG printer?

A:Yes, you can print shirts on your DTG printer using DTF ink. It’s not as good as specialized DTG ink but it will work fine. You will still need to pretreat your garments using your preferred pretreatment solution.

Q:What does DTF feel like?

A:The feel would depend on the type of powder you are using and the thickness of your ink layer. More ink will absorb more powder and make the overall result feel thicker. Our soft and stretchy DTF powder has better hand than traditional vinyl or other types of heat transfer. It’s elastic and soft to the touch. It is not softer than DTG prints however.