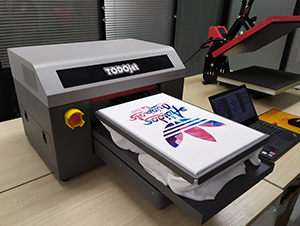

2.Digital Direct Jet Printing (DTG):

The direct injection process was born to solve the defects of heat transfer. The pigment ink is directly printed on the fabric, and then heated to fix the color. Digital direct injection printing is not only rich in colors, but also has a soft feel after printing and is very breathable. Because it does not require an intermediate carrier, it is currently the preferred process for high-end garment printing. The difficulty of direct printing on T-shirts lies in the application of dark fabrics, that is, white ink. The main component of white ink is phthalowhite powder, which is a white inorganic pigment composed of ultrafine particles with a particle size of 79.9nm, which has good whiteness, brightness and hiding power. However, because titanium dioxide has a great volume effect and surface effect, that is, strong adhesion, precipitation is prone to occur under a longterm prohibition; at the same time, the coating ink itself is a suspension liquid, which is not completely dissolved in the aqueous solution, so the white ink Poor fluency is the industry consensus.

3.Offset short board heat transfer