WHEN IS UV PRINTING THE RIGHT CHOICE?

-WHEN ENVIRONMENTAL IMPACT IS A CONCERN

-WHEN IT’S A RUSH JOB

-WHEN A SPECIFIC LOOK IS DESIRED

-WHEN SMUDGING OR ABRASION IS A CONCERN

-WHEN PRINTING ON PLASTIC OR NON-POROUS SUBSTRATES

WHEN IS UV PRINTING THE RIGHT CHOICE?

-

WHEN ENVIRONMENTAL IMPACT IS A CONCERN

Because evaporation is minimized, there are far fewer emissions of volatile organic compounds into the environment compared to other inks.

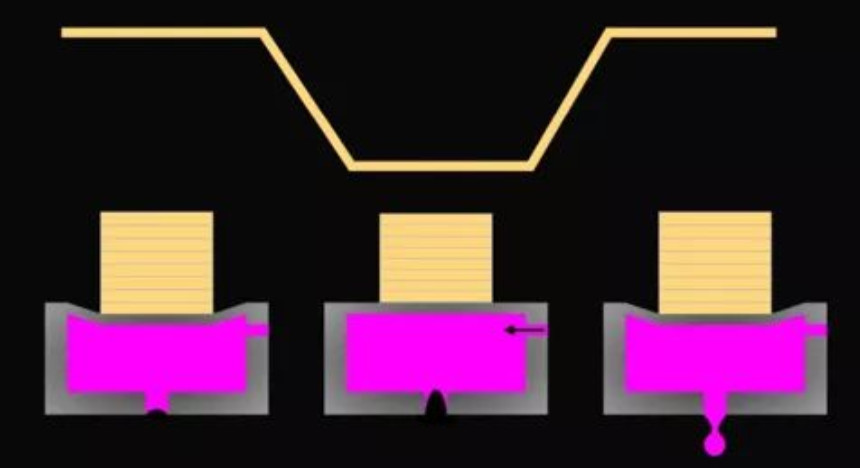

UV printing uses a photomechanical process to cure the ink versus drying through evaporation.

-

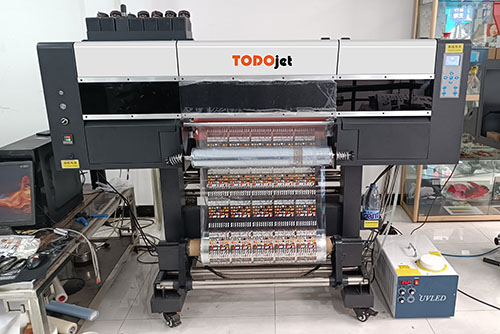

WHEN IT’S A RUSH JOB

Since there is no evaporation process to wait around for, UV inks don’t bring the down times other inks do while they dry. This can save time and get your pieces into the market much more quickly.

-

WHEN A SPECIFIC LOOK IS DESIRED

UV Printing is perfect for projects that need one of two looks:

- A crisp, sharp look on uncoated stock, or

- A satin look on coated stock

Of course, that doesn’t mean other looks can’t be accomplished. Talk to your printing rep to see if UV is right for your project.

-

WHEN SMUDGING OR ABRASION IS A CONCERN

The fact that UV printing dries instantly insures that regardless of how quickly you need the piece in hand, the work won’t be smudged and a UV coating can be applied to prevent abrasions.

-

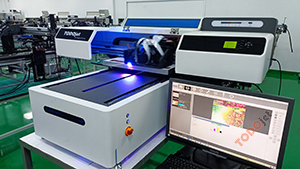

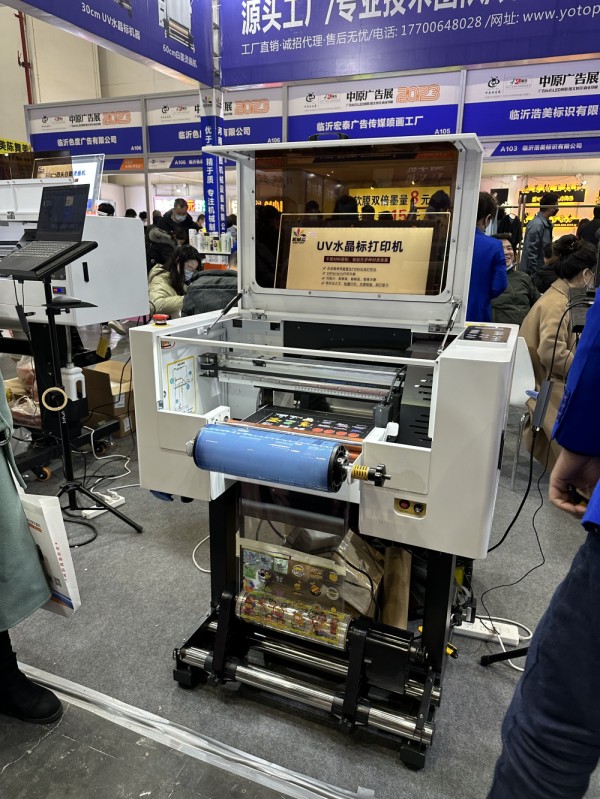

WHEN PRINTING ON PLASTIC OR NON-POROUS SUBSTRATES

UV inks can dry directly on the surface of materials. Since it’s not necessary for the ink solvent to absorb into the stock, UV makes it possible to print on materials that wouldn’t work with traditional inks.