- Hot peel. In order to achieve the effect of quick tearing, the main component of the release layer is wax, which is very unstable, not easy to melt and apply. For example, when we apply a release layer on the pet film, if a large amount of wax is applied, it is difficult to ensure uniformity.

- Cold peel. The release layer is dominated by the chemical component silicon, and the stability is much better than that of wax, which is easier to apply to the film, and the cold tear film is relatively stable. The cold tear film market is very mature, and Korean hot stamping is the principle of cold tear film.

Secondly, Pressing temperature.

- Hot peel . The required pressing temperature is generally between 140-150 ° C.

- Cold peel. The required pressing temperature is higher than that of the hot tear film, generally at 150-170 ° C, which needs to be determined according to the specific situation.

Thirdly, Pressing time.

- Hot peel: the pressing time is about 5-7 seconds.

- Cold peel: The pressing time needs to be determined according to the specific fabric.

Next, tear film time.

- Hot peel: 2-3 seconds can be satisfied to tear.

- Cold peel: It maybe about 30 seconds can tear film.

Then, glossiness.

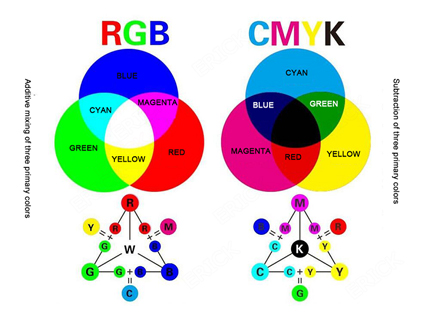

- Hot peel. After the transfer, the color will be more vivid, there are the following two reasons for reference:

(1) Due to the coating, the hot tear film has a strong ability to absorb ink, so the color after transfering is more vivid.

(2) After the hot tear film is cooled, it may cause color to adhere to the membrane, so that the effect is not well.

2.Cold peel. In general, the color of cold tear film is not as vivid as hot tear film.

Meawhile, wash firmness.