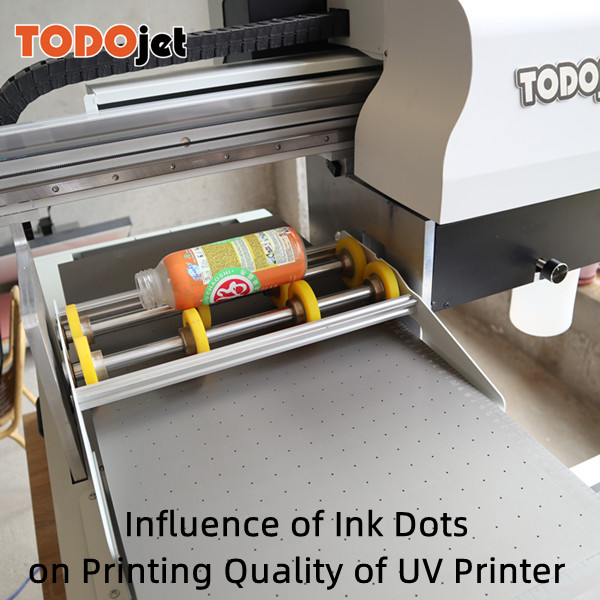

Wholesale DTF mini printing machine A3 XP600 printhead 30cm Roll to Roll DTF Printer

The production of heat transfer clothing is a hot project that has only emerged in recent years, which is heat transfer technology. Thermal transfer heat transfer technology has a wide range of market applications, widely used in clothing, T-shirts, luggage, handbags, shoes and hats, socks, gloves, aprons, handicrafts and other fields. Production of heat transfer, high elasticity, good washing fastness, brilliant color.

Company Profile

Zhengzhou Domax Machinery Company is engaged in R&D, production and sale of digital printers. we specializing in research, manufacture, sale and service of wide-format printer,UV flatbed printer, textile printer,fabric digital inkjet printing machine and related consumables.

By cooperating with world famous printhead manufacturers and software suppliers, we integrate exquisite and practical technology into our products. With 12 years experiences in printing filed, TODOjet can offer you printers with high quality, professional package and good service.Up to now,our printers have exported to many overseas market such as Europe, South America, Southeast Asia and Africa.

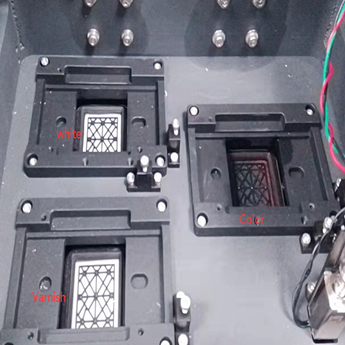

| Print head | 2pcs Epson XP600 heads |

| Print speed | 3-4.5sqm/h |

| Accuracy | 720*720dpi 4pass

720*1080dpi 6pass 720*1440dpi 8pass |

| Ink type | Pigment ink/Transfer film ink |

| Media Maximum Width | 32cm width |

| Media thickness | 1mm adjustable |

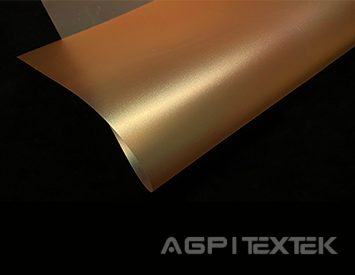

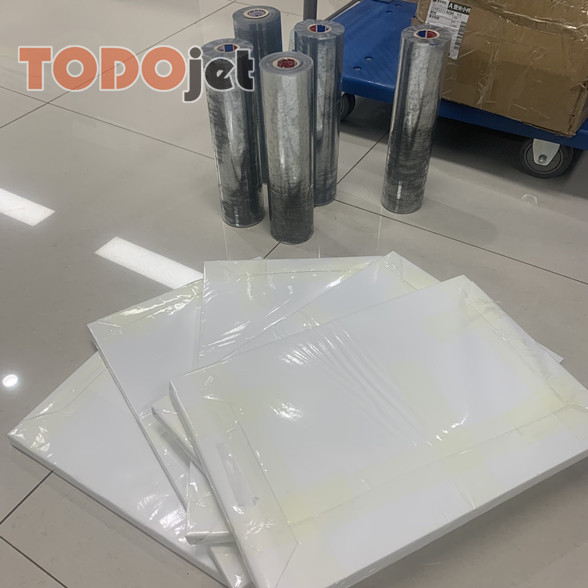

| Media type | PET film A3 size sheet / 30cm width roll |

| Heating system | Auto constant temperature drying system |

| Temperature | 160-170 cold/hot to tear |

| RIP software | Maintop |

| Power | AC110-220V, 50-60Hz, USB2.0, 350W |

| Operation environments | Temperature 20-30℃, Humidity 45%-65% |

| Machine size | 940*500*580mm |

| Packing size | 1000*640*640mm |

| Gross weight | 89kg |

Steps for using garment heat transfer: Adjust the thermostat and timer of the heat transfer machine to the desired temperature and time.

1. Lay the substrate flat on the silicone plate, then place the offset heat transfer drawing on the substrate, and press the handle down firmly until it is completely closed.

2. When the time indicated for hot stamping is up, the buzzer will sound, and the handle will be lifted back to its original position.

3. If it is cold torn, the heat transfer paper should be torn off after cooling; if it is hot torn, the heat transfer paper should be torn off immediately after hot stamping.